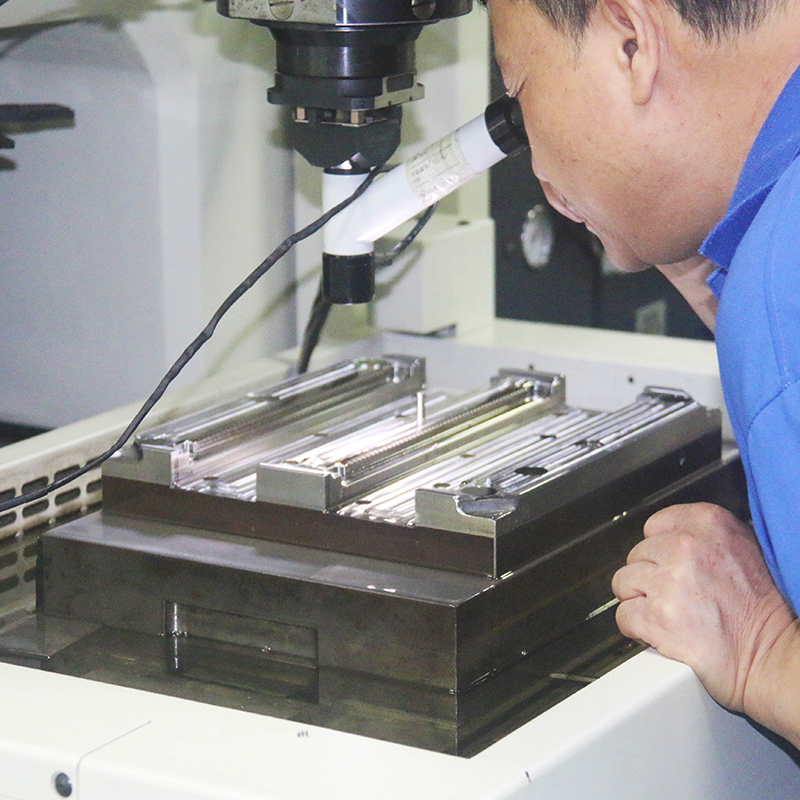

Wire cutting, or Wire EDM (Electrical Discharge Machining), is an advanced precision machining process that uses a thin, electrically charged wire to cut through conductive materials. Unlike traditional cutting methods, Wire EDM is capable of creating intricate, highly detailed parts with tight tolerances, making it a popular choice for industries that require high precision. In this comprehensive guide, we’ll explore the key principles, applications, and advantages of EDM wire cutting, along with how it compares to other cutting methods, and why it’s a go-to solution for manufacturers worldwide.

At Toolingsun, we specialize in providing high-quality wire EDM services, offering solutions tailored to your specific manufacturing needs. Whether you’re designing custom parts for aerospace, automotive, or medical applications, our team is equipped to deliver precise, cost-effective solutions that meet the highest standards of quality.

What Is EDM Wire Cutting and How Does It Work?

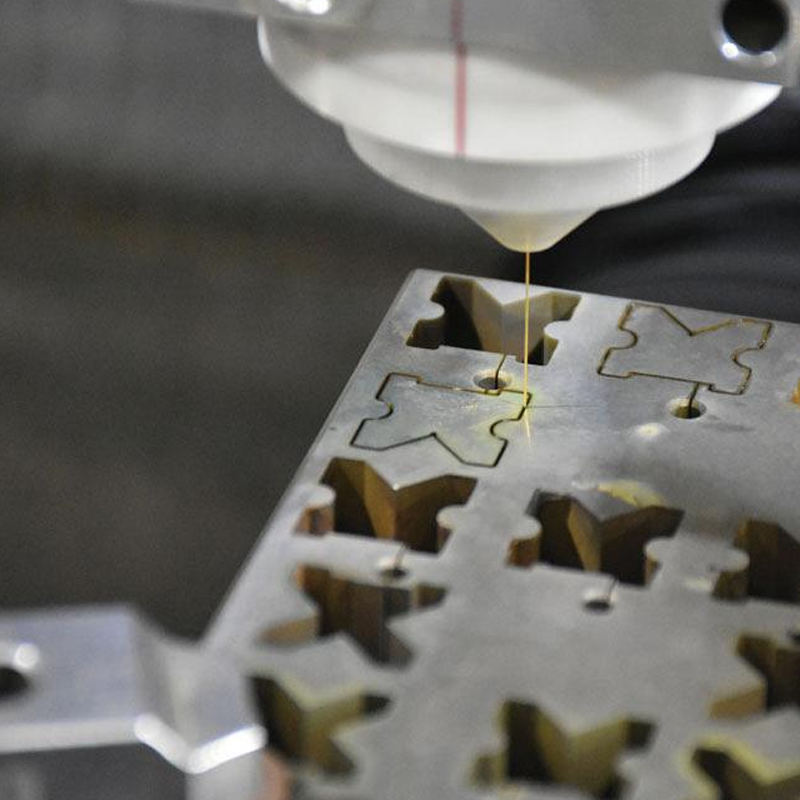

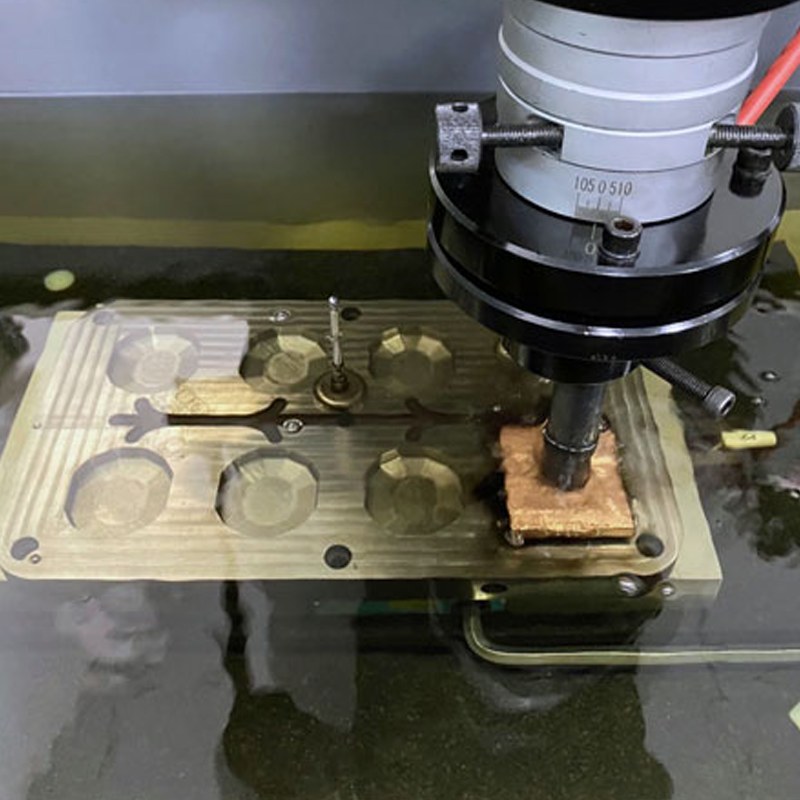

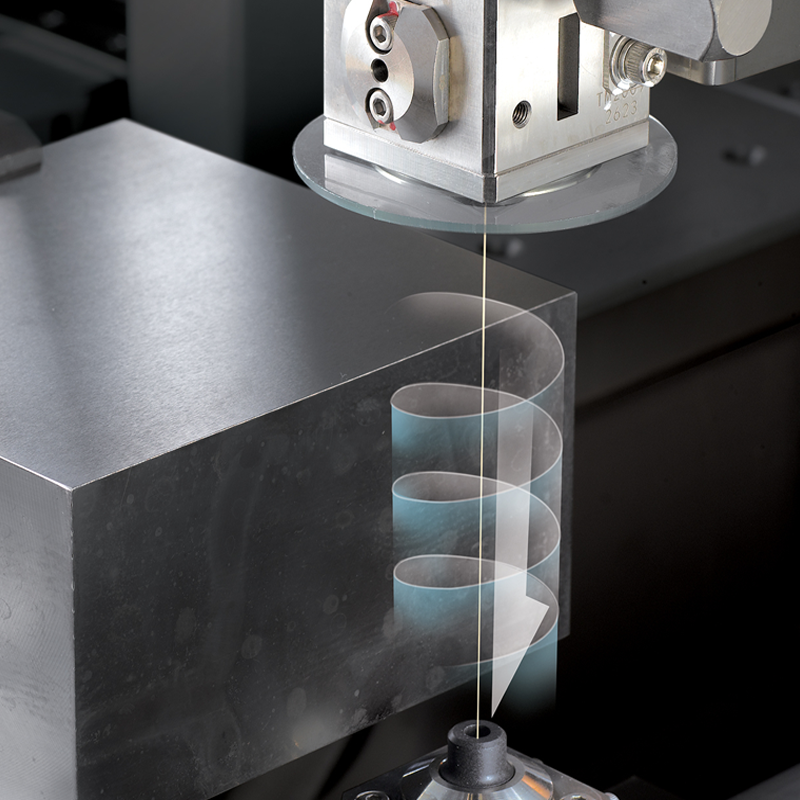

EDM wire cutting utilizes a continuously moving thin metal wire, typically made from materials like molybdenum or copper, as an electrode to cut through a conductive workpiece. This process uses pulsed electric discharges between the wire and the workpiece to remove material, allowing for precise cutting and shaping.

The process begins with the wire, which is connected to the negative terminal of a pulse power supply. The workpiece is connected to the positive terminal. When a pulse voltage is applied, a spark discharge occurs between the wire and the workpiece, reaching temperatures over 10,000°C at the discharge point. This intense heat melts and vaporizes the material, creating small explosions that eject the molten metal, allowing for a highly controlled cutting process.

Types of EDM Wire Cutting:

Wire EDM can be categorized based on the speed of the electrode wire movement:

- High-Speed Wire EDM: Machines with high-speed reciprocating wire movement (8-10 m/s) for rapid cutting.

- Low-Speed Wire EDM: Machines with unidirectional low-speed wire movement (0.2 m/s), ideal for fine details and high precision.

- Medium-Speed Wire EDM: A combination of high-speed wire for roughing and low-speed wire for finishing, offering a balance between speed and precision.

Each of these categories offers distinct advantages depending on the application, from rapid prototyping to highly detailed part production.

Key Characteristics of EDM Wire Cutting

Wire EDM offers several distinct benefits, making it ideal for producing complex parts that require precision and durability:

- High Precision: With accuracy levels as fine as ±0.01mm, EDM wire cutting produces parts with exceptional dimensional accuracy and surface finishes of Rα 1.25-2.5um.

- Flexible Shapes: EDM wire cutting excels in creating intricate shapes and parts with sharp corners or tight tolerances, ideal for complicated geometries.

- Minimal Heat Effect: The localized heat generated during the process ensures minimal thermal distortion, making it perfect for heat-sensitive materials.

- Non-Contact Process: Wire EDM is a non-contact process, meaning no mechanical force is applied to the workpiece, which is crucial for parts made from brittle materials or low-stiffness components.

- High Material Utilization: With a narrow cutting width, EDM minimizes material waste, making it an excellent choice for high-cost materials like precious metals.

While the process is known for its precision, it does have its limitations, such as slower cutting speeds and higher costs compared to other methods like laser cutting or water jet cutting. It also requires the material to be conductive, limiting its use to certain applications.

Common Materials for EDM Wire Cutting

Wire EDM can process a wide range of conductive materials, including:

- Carbon Tool Steel: Known for its high hardness after heat treatment, commonly used for molds and dies.

- Alloy Tool Steel: Offers high hardenability and wear resistance, making it ideal for complex molds.

- Cemented Carbide: High hardness and stability, perfect for making intricate and durable molds, though it requires slower cutting speeds.

- Aluminum: Lightweight and durable, with good EDM performance but moderate surface roughness.

- Copper and Brass: Often used in specialized applications like electrical components and precise connectors.

These materials are used extensively in industries like aerospace, automotive, and medical device manufacturing, where precise, high-performance components are required.

Wide Application of EDM Wire Cutting

Wire EDM is used in various industries where high precision is paramount. Some of the key applications include:

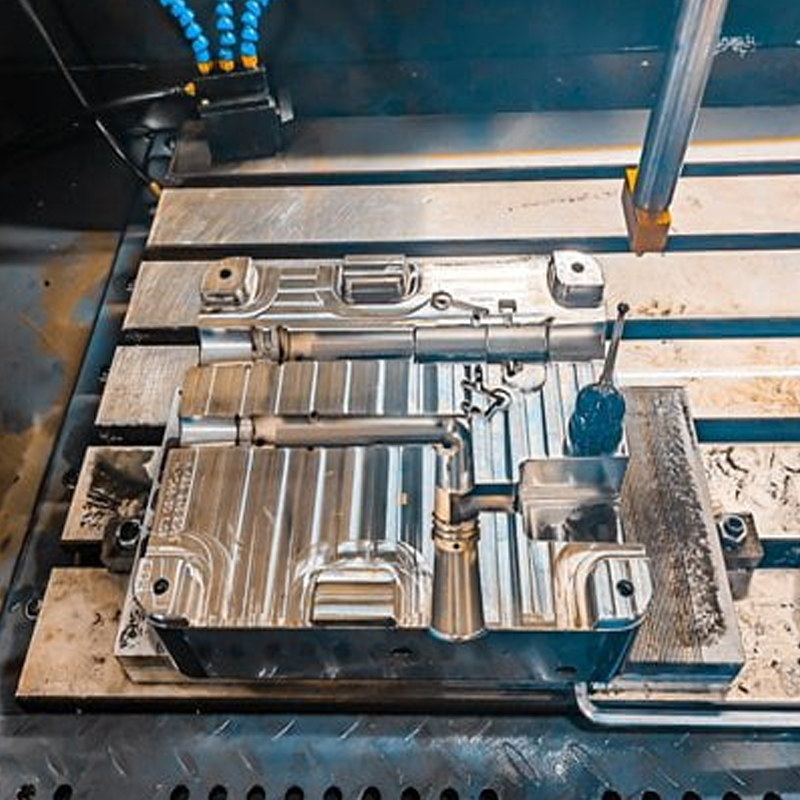

- Mold Processing: Wire EDM is commonly used for processing plastic and stamping molds. It can precisely create cavities and cores for molds, as well as mold bases and clamp plates.

- New Product Trials: In product development, wire EDM allows for quick prototyping of parts, which can significantly reduce development cycles.

- Cutting Hard-to-Process Parts: Wire EDM is ideal for making precision-shaped holes, templates, and narrow slots, especially in materials that are difficult to machine with traditional methods.

- Precious Metal Cutting: Due to its small electrode wire, wire EDM is perfect for cutting precious metals with minimal material waste.

Industries That Benefit from EDM Wire Cutting

EDM wire cutting is widely used across various industries for producing complex, high-precision parts:

- Aerospace and Defense: Wire EDM is essential for making intricate parts like aircraft engine blades, missile components, and other aerospace accessories.

- Automotive: Used for manufacturing complex components such as transmission gears, rocker arms, and crankshafts.

- Medical Devices: EDM wire cutting is commonly used to produce surgical tools, implants, and endoscopes, where precision and reliability are critical.

- Jewelry and Electronics: The technology is also widely used in the jewelry industry for creating fine details and in electronics for making intricate connectors and components.

Electrode Wire Selection: A Critical Component

The choice of electrode wire is crucial in EDM wire cutting. The wire must possess good conductivity, high tensile strength, and erosion resistance. Some of the common wire materials include:

- Tungsten Wire: Known for high tensile strength, typically used for fine cuts.

- Brass Wire: Suitable for slower processes, providing good surface finishes and straightness but with lower tensile strength.

- Molybdenum Wire: Ideal for high-speed cutting, offering excellent tensile strength.

The selection of wire material and diameter depends on the specific requirements of the job, such as cutting thickness, material hardness, and required precision.

Comparison with Other Cutting Methods

Wire EDM offers unique advantages compared to other cutting methods like laser cutting, water jet cutting, and plasma cutting:

- Laser Cutting: Best for materials that can be cut with high precision using a laser beam but lacks the ability to cut metals as thick as wire EDM.

- Water Jet Cutting: Suitable for a wide range of materials, including non-metals, but generally slower than wire EDM.

- Plasma Cutting: Ideal for thicker materials but has lower precision compared to wire EDM.

Wire EDM stands out for its high precision, especially for parts with intricate details or tight tolerances. However, it is generally slower than laser or plasma cutting and may not be as cost-effective for mass production.

Conclusion: Why Choose Toolingsun for EDM Wire Cutting?

At Toolingsun, we understand the importance of high-quality precision machining. Our EDM wire cutting services are designed to meet the most demanding industry standards, ensuring that your parts are manufactured with the utmost precision. With our expertise in wire EDM, we can deliver solutions tailored to your unique needs, whether you require small prototype runs or large-scale production.

Our commitment to providing OEM services, high-quality manufacturing, and custom solutions means you get the best results every time. From aerospace components to intricate medical devices, we have the technology and experience to handle all your wire EDM cutting needs.

Ready to learn more about how EDM wire cutting can enhance your next project? Contact us today to discuss your custom manufacturing requirements, and let Toolingsun help you bring your vision to life with precision and efficiency.