Overview:

The Custom Premium Hot Runner Silicone Ketchup and Salad Bottle Cap Valve Seal Mold Tooling is a highly engineered solution designed for the production of silicone valve seals for condiment bottle caps, including ketchup and salad dressing containers. These molds are constructed from premium materials such as steel or aluminum alloys, ensuring superior durability and precision. Utilizing advanced hot runner technology and injection molding processes, our molds guarantee flawless component production, delivering superior sealing performance for high-volume food packaging applications. Ideal for OEMs in the food industry, our molds offer custom-tailored solutions, ensuring leak-proof, high-performance seals that meet rigorous food safety standards. With adherence to international certifications like ISO 9001 and IATF 16949, our molds deliver consistency, reliability, and extended service life.

![]()

![]()

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Steel, Aluminum Alloy |

| Runner System | Hot Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD |

| Sample | Available |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom |

| MOQ | According to your requirement |

| Lead Time | Approximately 25-30 days |

Surface Treatment Options:

- Nickel Plating: Enhances corrosion resistance, ensuring durability in food-grade environments and significantly extending the mold’s service life under continuous use.

- Hard Anodizing: Increases surface hardness and wear resistance, providing better protection against abrasion, which is crucial for precision molds used in high-volume silicone molding applications.

- Chromium Plating: Offers superior wear resistance and corrosion protection, ideal for molds exposed to food-grade silicone and other challenging materials in condiment packaging.

- Polishing: Refines the surface of the mold to minimize friction during the molding process, enhancing the smoothness and finish of the molded valve seals, thereby improving sealing efficiency.

Quality Assurance:

Our quality assurance process is integral to producing the highest-quality Custom Premium Hot Runner Silicone Ketchup and Salad Bottle Cap Valve Seal Mold Tooling. With ISO 9001 and IATF 16949 certifications, we adhere to global standards in quality management. Our comprehensive testing includes first-article evaluations, in-process quality checks, and final product assessments. To guarantee precision, we utilize advanced tools such as coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers. Automated vision systems and rigorous material testing ensure each mold meets exact specifications for durability, precision, and reliability in demanding food packaging environments.

Application and Benefits:

- Precision Silicone Valve Seals: Ensures a perfect fit for ketchup, salad, and condiment bottle caps, creating an airtight, leak-proof seal.

- Food-Grade Safety: Molds are designed to meet strict food safety and hygiene standards, ensuring consumer safety and compliance with regulations.

- High-Volume Production: Hot runner systems reduce cycle times, enabling high-volume production with uniform, defect-free results.

- Durability: The premium steel or aluminum alloy construction, combined with surface treatments, ensures long mold life even under continuous use.

Customization and Services:

- Tailored Design: Our molds are customized to meet specific customer requirements, ensuring a perfect fit for the desired valve seal dimensions and material properties.

- Prototyping: We offer rapid prototyping services to test and validate mold designs before full-scale production.

- Mold Flow Analysis: Advanced mold flow simulation tools ensure optimal material flow, minimizing defects and enhancing production efficiency.

- Post-Production Inspection: Each mold undergoes comprehensive testing for dimensional accuracy, surface finish, and operational integrity before delivery.

Our Custom Premium Hot Runner Silicone Ketchup and Salad Bottle Cap Valve Seal Mold Tooling offers unmatched precision, performance, and durability, making it the ideal solution for high-quality condiment packaging.

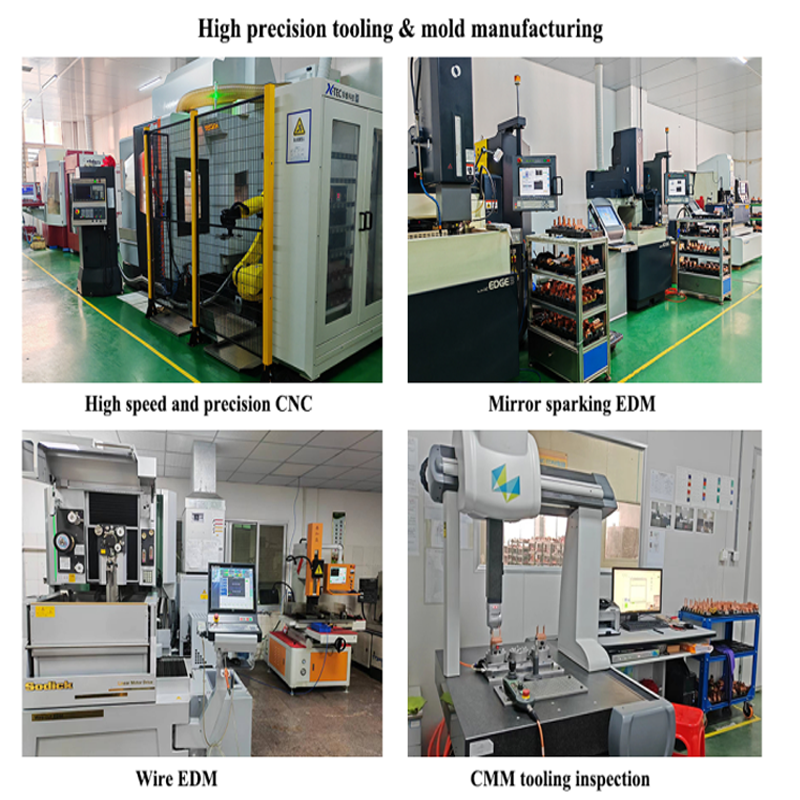

Factory Show:

Our facility is equipped with cutting-edge manufacturing technologies, including CNC machining, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC), enabling the production of molds with micron-level accuracy. With a fleet of rubber compression molding presses and LSR injection molding machines, we efficiently handle both small and large-scale production runs while maintaining consistent quality. Our ISO 9001 and IATF 16949-certified quality control systems include 3D projectors, sealing testers, durometers, and elasticity gauges to verify mold performance and material integrity at each stage. Automated systems, such as AutoDryers, high-speed doming machines, and precision die-cutting technology, enhance our production efficiency, ensuring rapid delivery and exceptional mold quality.