Success in the injection molding industry is not just about having the best equipment or the latest technology—though those certainly help. The real key to achieving manufacturing excellence lies in the alignment between injection molders and toolmakers. At Toolingsun, we understand that the true measure of success is how well these two vital players in the process work together to meet the complex needs of customers. When it comes to custom injection molding for intricate applications, under tight timelines and cost constraints, effective collaboration is paramount.

Having the right tools is important, but it’s the relationship between molders and toolmakers that determines the quality, speed, and cost-effectiveness of the final product. This alignment creates a cohesive team, where both sides share a common vision and collaborate seamlessly to ensure manufacturing success.

Building Strong Partnerships Between Injection Molders and Toolmakers

For custom injection molders like Toolingsun, the collaboration with top-tier toolmakers is more than just a transaction; it’s a partnership rooted in consistent performance, problem-solving, and trust. Over time, through hundreds of projects, a deep understanding develops between these two parties, fostering an environment where both contribute equally to the final product.

Successful injection molding is dependent on precision, efficiency, and the ability to overcome challenges. When molders and toolmakers work together toward a shared goal, they not only ensure that projects are completed on time and within budget, but they also enhance the overall quality of the work. Here’s how this collaboration brings value:

- Sharing Best Practices: As molders and toolmakers work closely together, they exchange valuable insights and practices that lead to the creation of better tools and more efficient manufacturing methods.

- Strategic Capability Expansion: Both parties continuously seek opportunities to expand their capabilities and enhance their processes, ensuring they stay ahead of the curve in a highly competitive industry.

- Fostering Trust: With clear communication and a shared vision, molders and toolmakers develop mutual trust that allows for more creative problem-solving and higher levels of innovation.

At Toolingsun, we believe that these long-term relationships are essential to the success of our custom injection molding projects. We’ve built a network of highly reliable toolmakers who understand our exacting standards, ensuring high-quality tooling and faster production times for our clients.

Tailoring Tooling Solutions for Diverse Needs

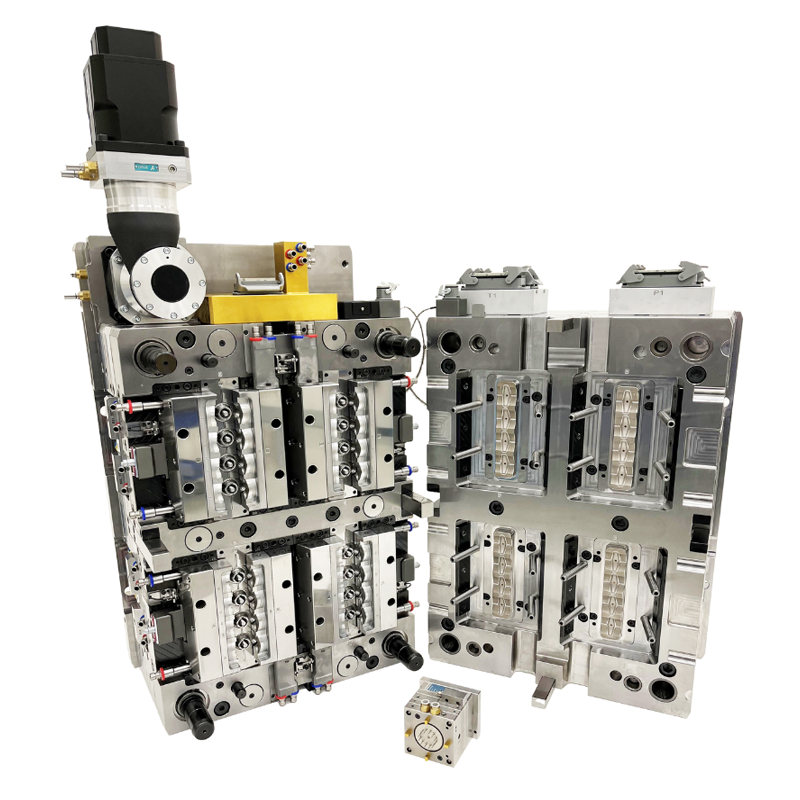

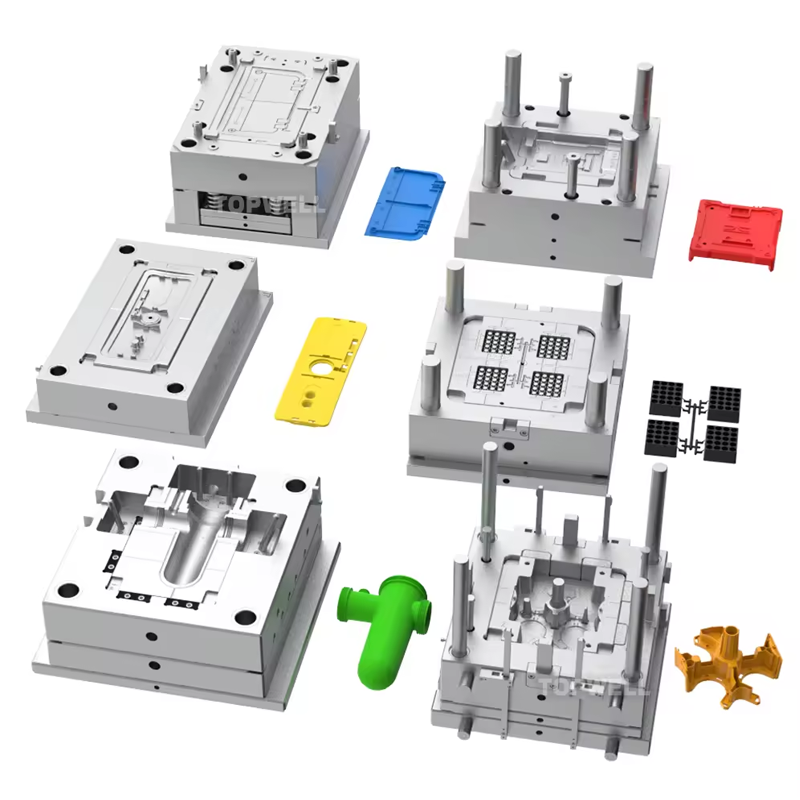

Not all tooling needs are the same. In fact, different projects demand different approaches, and having the right tooling partner can make all the difference. Toolingsun has built a trusted network of “go-to” toolmakers who are skilled in producing both basic, low-cost tools and more complex, multi-cavity or multi-sized tools. Here’s how the right tooling partner adds value:

- Accurate Tool Quoting: Toolmakers with a deep understanding of our design and build standards are able to provide accurate quotes for tooling projects, ensuring the project can be completed in the shortest time possible at the lowest cost.

- Collaborative Tool Design: The tooling process begins with a collaboration on material selection, design analysis, and addressing potential design flaws that could cause defects in the final product.

- Efficient Secondary Operations: Toolmakers work with us to streamline secondary operations, like polishing and texture application, that further enhance the final part.

At Toolingsun, we pride ourselves on building long-term relationships with trusted tooling suppliers who not only meet but exceed our customers’ expectations for quality and efficiency.

The Role of Communication in Tooling Success

In any successful partnership, communication is key, and that is especially true when it comes to the alignment between injection molders and toolmakers. Toolingsun takes a proactive approach to stay connected with our toolmaking partners, ensuring that we are all on the same page when it comes to project goals and expectations.

Effective communication involves more than just regular meetings. At Toolingsun, we use various channels, including phone calls, video conferencing, and sometimes even on-site visits, to establish the design approach, review tool designs, and ensure that everything is progressing as expected. This level of communication helps us:

- Approve tool designs quickly

- Resolve any design issues before production begins

- Stay ahead of any potential delays

- Streamline the tool approval process

We also extend this communication to our network of vendors who support the tool-making process, such as polishers, welders, jig grinders, and texture houses. By maintaining a reliable network, Toolingsun can offer fast response times and consistent quality for our clients.

Streamlining Manufacturing Processes with Tooling Partnerships

Working with trusted tooling partners also means that manufacturers can take advantage of cost-saving measures that lead to better bottom-line results. When using advanced tooling manufacturing techniques, like design for manufacturability (DFM), we are able to anticipate any potential production issues before they arise. This foresight not only reduces delays but also ensures that our tooling designs are optimized for efficient production.

DFM allows us to assess how easy a part is to manufacture, optimizing the design process to eliminate any unnecessary steps that could lead to higher costs. By integrating DFM early in the design phase, Toolingsun helps clients avoid costly mistakes and ensures that the parts are made exactly as intended. This process plays a crucial role in ensuring that tooling is manufactured correctly, leading to greater efficiency and reduced rework.

The Benefits of Effective Toolmaker Alignment

When injection molders and toolmakers align themselves with the same set of goals and expectations, the results speak for themselves. Here are some key benefits of a strong partnership:

- Enhanced Efficiency: With clear communication and a shared vision, projects can be completed faster, helping customers meet their deadlines and reduce lead times.

- Improved Quality: By working together, injection molders and toolmakers can identify potential issues and design flaws early in the process, resulting in higher-quality products.

- Lower Costs: By streamlining the process, reducing errors, and improving production speed, the overall cost of manufacturing is lowered. This helps clients save money while maintaining top-tier quality.

- Long-Term Relationships: Building a trusted relationship between injection molders and toolmakers creates a solid foundation for future projects, making it easier to scale up production or develop new products.

At Toolingsun, we understand the importance of these partnerships. Our focus on providing high-quality custom service and a one-stop solution ensures that our clients receive the best possible tooling and injection molding services.

Conclusion

Successful custom injection molding is more than just about having the best machinery; it’s about aligning your team with reliable and skilled toolmakers. At Toolingsun, we’ve built long-lasting relationships with top-tier toolmakers to ensure that your products are manufactured efficiently, cost-effectively, and with the highest quality.

By focusing on design for manufacturability (DFM), optimizing our toolmaking process, and maintaining clear communication, we help our customers bring their products to life faster and more efficiently. Whether you need simple tooling or complex multi-cavity molds, Toolingsun offers a comprehensive solution designed to meet your unique needs. Contact us today to discuss how our custom tooling solutions can elevate your manufacturing process.