In the world of injection molding, the design and production of plastic toilet cover tooling molds represent a critical and often overlooked process that requires precise planning, careful execution, and a deep understanding of both materials and manufacturing technologies. Whether it’s for residential or commercial toilet covers, the need for high-quality, durable, and cost-effective molds is paramount. At Toolingsun, we specialize in delivering high-precision, custom tooling solutions for the bathroom industry, including the manufacturing of plastic toilet cover molds that ensure seamless production, longevity, and excellent performance.

Introduction to Plastic Toilet Cover Tooling Molds

Plastic toilet covers, a staple in everyday sanitation, are typically manufactured through an injection molding process that requires highly specialized molds. These molds shape the final product, ensuring it meets strict standards for functionality, aesthetics, and durability. Given the nature of the product, it is crucial for manufacturers to focus on high-quality tooling designs that can endure high volumes of production while maintaining the desired specifications.

At Toolingsun, our expertise in mold design and manufacturing processes makes us the ideal partner for your toilet cover tooling needs. With a comprehensive one-stop service, we handle every aspect of the tooling process from the initial design phase through to the final production, ensuring that you receive a product that adheres to the highest industry standards.

The Production Process for Plastic Toilet Cover Tooling Molds

The production of plastic toilet cover molds involves several key steps, each of which requires careful consideration to ensure the highest quality and efficiency. Below is an outline of the critical steps involved in producing a plastic toilet cover tooling mold:

1. Design Phase: Understanding the Product and its Requirements

Before any tooling work begins, it’s essential to understand the product’s functional and aesthetic requirements. For a toilet cover mold, these could include precise dimensional tolerances, strength, ease of use, and, in some cases, additional features like hinges or soft-close mechanisms. This step typically involves a detailed review of the product’s design, materials, and desired features.

At Toolingsun, we emphasize Design for Manufacturability (DFM), which ensures that the mold design is optimized for efficient and cost-effective production. By considering the manufacturing processes early in the design phase, we can identify potential challenges, reduce production time, and prevent costly design alterations later on.

2. Material Selection: Choosing the Right Materials for Durability

The choice of material for the mold is crucial in determining the performance of the plastic toilet cover. Common materials used for the toilet cover mold include ABS (Acrylonitrile Butadiene Styrene), polypropylene, and polyethylene, which offer the necessary balance of strength, flexibility, and cost-effectiveness.

Additionally, the mold material itself, usually steel or aluminum, must be chosen carefully. Steel molds, while more expensive, offer a longer lifespan and are ideal for high-volume production. On the other hand, aluminum molds are cost-effective for lower-volume runs but tend to wear out more quickly. Toolingsun offers a range of material choices to meet your specific production needs and budget.

3. Tooling Design and Manufacturing: The Heart of the Process

Once the materials are chosen and the design parameters are clear, the next step is to design and manufacture the mold itself. This involves the creation of precise CAD (Computer-Aided Design) drawings that detail the intricate features of the mold.

For toilet cover molds, this often includes designing cavities, runners, cooling channels, and ejector systems that ensure smooth material flow during injection molding. Cooling channels are particularly critical in achieving uniform cooling and minimizing defects such as warping or sink marks.

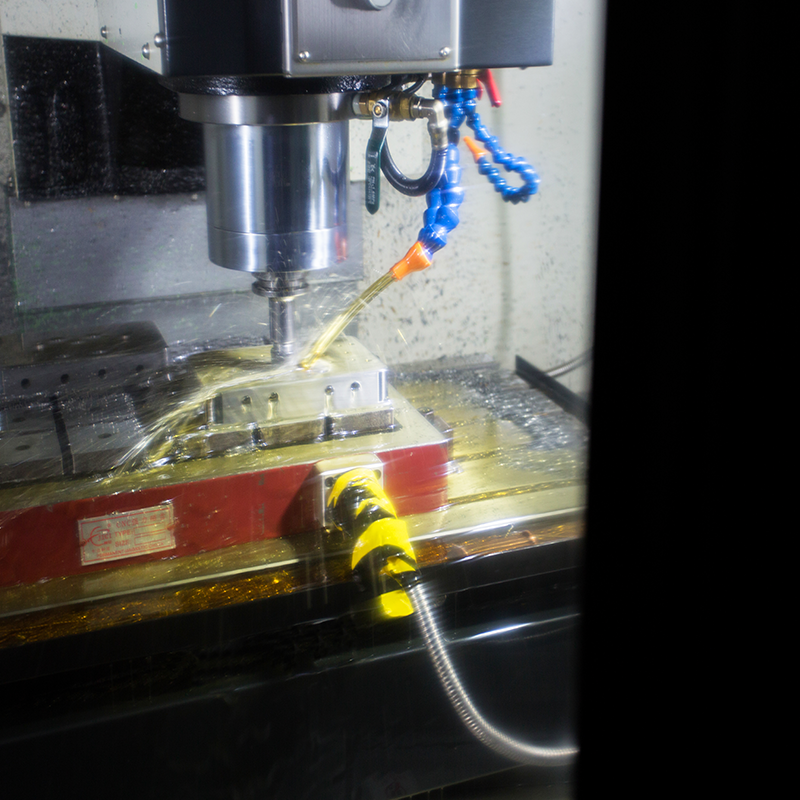

Toolingsun’s team of expert engineers uses advanced CAD/CAM software to develop highly accurate tooling designs. Our state-of-the-art CNC machining technology allows us to manufacture complex mold components with micron-level precision, ensuring consistency and high-quality output in every production run.

4. Prototype and Testing: Ensuring Accuracy Before Full Production

Before committing to full-scale production, it is essential to produce a prototype of the toilet cover mold to test its functionality. This prototype is tested for dimensional accuracy, surface finish, and performance in a simulated production environment.

At Toolingsun, we conduct comprehensive prototype testing to ensure that every mold meets the necessary specifications. We also evaluate the mold’s ability to produce the final product without defects and assess the mold’s durability under different operating conditions. This phase allows us to make any necessary adjustments before moving to mass production.

5. Injection Molding: Production and Quality Control

Once the mold has passed testing, it moves to the production phase. In injection molding, plastic pellets are melted and injected into the mold cavity under high pressure, where they cool and solidify into the shape of the toilet cover.

During this phase, quality control is vital to ensure that the final product meets all dimensional, functional, and aesthetic specifications. At Toolingsun, we employ a strict quality assurance process that includes in-line inspection, testing for defects such as warping, cracks, or uneven surface finish.

6. Post-Processing: Adding Finishing Touches

After the molded toilet covers are ejected from the mold, they may undergo additional post-processing steps such as trimming, surface polishing, or the addition of logos and other markings. Assembly operations, including adding hinges or soft-close components, are also performed at this stage.

Key Design Considerations for Plastic Toilet Cover Tooling Molds

When designing tooling molds for plastic toilet covers, several key factors must be considered to ensure the product’s functionality, cost-effectiveness, and longevity:

1. Part Geometry and Features

Toilet covers often have a complex shape that requires precise mold design to ensure accurate part production. The inclusion of features such as hinges, locking mechanisms, and soft-close systems requires special attention during the design phase to ensure ease of injection and efficient cycle times.

2. Material Flow and Cooling Systems

Effective material flow is essential in ensuring that the molded parts are free from defects such as air pockets, sinks, or surface imperfections. Well-designed cooling channels are crucial for maintaining uniform temperature distribution across the mold and preventing issues such as warping or distortion.

3. Ejection System Design

The ejection system must be designed to safely and efficiently remove the toilet covers from the mold without causing damage. This system is typically equipped with ejector pins or plates that push the cooled part out of the mold cavity. The ejection system must be optimized for each mold to prevent part deformation and ensure smooth removal.

4. Tool Durability and Maintenance

To maximize the efficiency and lifespan of the mold, tool durability is a key consideration. The material used to manufacture the mold should be able to withstand the wear and tear of continuous use without degrading. Regular maintenance of the molds is also essential to prevent downtime and ensure that the tooling remains in peak condition throughout the production process.

Conclusion: Why Choose Toolingsun for Your Plastic Toilet Cover Tooling Needs?

At Toolingsun, we offer a one-stop service for all your plastic toilet cover tooling needs. From custom mold design to high-quality manufacturing and post-production services, we ensure that every step of the process is executed with precision and care. Our team of skilled engineers works closely with you to deliver molds that meet your exact specifications, all while maintaining the highest standards of quality and efficiency.

Whether you’re looking to produce high volumes of toilet covers or require specialized design features, Toolingsun has the expertise and equipment to bring your vision to life. With our custom service, advanced technology, and commitment to excellence, we are your trusted partner in creating the perfect tooling for your plastic toilet covers.

Contact Toolingsun today to learn more about how we can help you achieve the highest-quality molds for your plastic toilet cover production needs!