Overview:

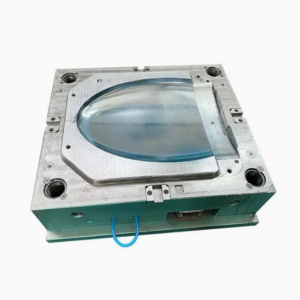

Our factory specializes in crafting high-precision injection molding tools specifically designed for the production of PP/ABS toilet seat cover lids. These molds are engineered for durability and exceptional performance, meeting the demands of high-volume manufacturing with precision and consistency. Using high-quality steel alloys like P20, 718, or NAK80, our molds undergo advanced CNC machining, EDM (Electrical Discharge Machining), and precision surface finishing to achieve unparalleled accuracy. Whether you require single-cavity or multi-cavity molds, our tools are tailored to ensure smooth, defect-free production of toilet seat covers, delivering a high-quality finish and reliable performance over extended production runs. Our one-stop service includes everything from design and prototyping to full-scale manufacturing, all while adhering to strict industry standards.

Basic Information:

| Attribute | Details |

|---|---|

| Mold Type | Injection Mold |

| Mold Material Options | P20, 718, NAK80, S136, 2738 |

| Mold Base Standards | HASCO, DME, MISUMI, LKM, JIS |

| Mold Runner System | Cold Runner / Hot Runner |

| Mold Gate Options | Pin-point Gate, Sub Gate |

| Cavity | Single or Multi-Cavity |

| Design Software Supported | UG, PROE, CAD, SOLIDWORKS |

| Molding Equipment Used | CNC, EDM, Wire Cutting, Milling Machine |

| Compatible Raw Materials | PP, ABS |

| Packaging Method | Wooden Pallet or Carton |

| OEM Services | Available — Please provide 2D/3D files or samples |

| Lead Time | Approximately 30 days |

Surface Coating Options:

- Mirror Polishing:

Provides a glossy, smooth surface that enhances the aesthetic appearance of the toilet seat cover molds, perfect for creating high-quality finishes on the final product. - Textured Etching (Chemical or Laser):

Custom grain or texture patterns applied to the mold surface enhance the functionality of the toilet seat covers, providing better grip or appearance. - Hard Chrome Plating:

Coats the mold surface with a hard, wear-resistant chrome layer, significantly increasing mold life, ideal for high-volume runs of toilet seat lids. - Nitriding Treatment:

Increases the mold surface hardness, providing superior resistance to wear and abrasion while maintaining high dimensional precision over extended cycles.

Benefits of Our Tooling:

- Precision-Matched Tooling Design

Advanced CNC machining and EDM processes ensure micron-level accuracy (±0.005mm), crucial for creating precise geometries in toilet seat cover molds, reducing defects and ensuring smooth part ejection. - Multi-Material Compatibility

Our tooling is optimized to handle both PP and ABS, the most commonly used materials in the manufacturing of toilet seat covers. Enhanced venting systems ensure flawless molding, while temperature-controlled channels guarantee optimal molding conditions. - Extended Tool Lifespan

Hardened steel cores and DLC (Diamond-Like Carbon) coatings or Nickel-PTFE coatings significantly enhance resistance to abrasion, corrosion, and polymer adhesion, enabling the molds to endure high-volume runs with up to 500K+ cycles. - Rapid Cycle Time Optimization

Optimized cooling channels and automated ejection systems are incorporated to reduce cycle times, boosting productivity by up to 30% for high-volume orders without compromising on surface finish or part quality.

Quality Assurance:

Our molds undergo stringent quality assurance procedures that adhere to the highest industry standards. Our ISO 9001 certification ensures consistent and reliable mold production. The molds are subjected to comprehensive dimensional checks using Mitutoyo Coordinate Measuring Machines (CMM) for accuracy. Surface finish analysis is performed with Keyence optical comparators, while material integrity is verified with Rockwell hardness testers. Additionally, we perform mold flow simulations and evaluate the production-grade molds through LSR trial runs to ensure flawless performance. All materials used are traceable with mill certificates, and critical components undergo wear testing using Taber abrasion testers. We also conduct rigorous evaluations for compliance with IATF 16949 and FDA standards, ensuring our tooling solutions are built to last and maintain peak performance in production.

Factory Show:

Our advanced facility is equipped with high-precision CNC machines, EDM, and wire-cutting technologies to ensure superior mold fabrication accuracy. With a fleet of molding machines, including high-speed injection units, we maintain fast cycle times and high-quality production. Each mold is subjected to thorough testing for wear resistance, precision, and operational consistency. Backed by our expert team, we offer world-class tooling solutions tailored to meet the needs of your high-volume manufacturing projects.

This comprehensive tooling approach ensures your Customized Injection Mold Mould Tooling for PP/ABS Toilet Seat Cover Lids is optimized for efficiency, durability, and superior performance in every production cycle.