Overview:

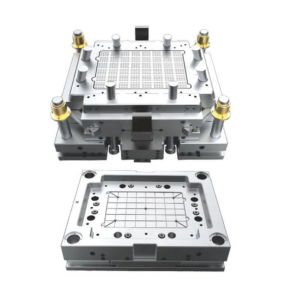

Our factory specializes in manufacturing Personalized P20 Blow Press Casting Punching and Stamping Tooling Molds, engineered for professional industrial applications across automotive, aerospace, packaging, and heavy machinery sectors. Built from premium-grade P20 tool steel and alternative high-performance alloys, these molds are designed to deliver superior strength, dimensional stability, and extended operational life under high-pressure forming and stamping conditions. By integrating advanced CNC machining, precision EDM, heat treatment, and surface grinding technologies, we ensure ultra-tight tolerances, mirror-level finishes, and consistent mold performance for high-volume production. With full OEM customization, we provide complete support from design, prototyping, and mold trials to mass production, delivering cost-effective and high-precision solutions tailored to your exact specifications.

Basic Information:

| Specification | Details |

|---|---|

| Material Options | P20 Tool Steel (standard), H13, SKD11, Stainless Steel, or Alloy Steels |

| Sample Lead Time | 10–20 days |

| Production Lead Time | 4–6 weeks |

| Process | CNC Machining, Heat Treatment, Mirror EDM, Precision Grinding, Wire EDM |

| Surface Finish | Polished, Textured, or Custom (Ra ≤ 0.6 μm) |

| Customization | Full OEM Service (Design to Production), Personalized Industrial Use |

| Certifications | ISO 9001, IATF 16949, RoHS Compliance |

| Application | Blow Press, Casting, Punching, and Industrial Stamping |

Benefits of Our Mold:

- Durable P20 Steel Core

Optimized hardness (28–32 HRC) ensures high machinability with outstanding wear resistance, providing a long-lasting balance between toughness and performance. - Precision Forming and Stamping Performance

Multi-axis CNC and EDM machining achieve dimensional tolerances of ±0.005 mm, ensuring accurate fit and repeatability for complex industrial applications. - Enhanced Surface Treatment

Polishing and nitriding deliver smooth, wear-resistant mold cavities, minimizing sticking, improving part release, and extending tool life in high-cycle operations. - High-Pressure & Thermal Stability

Designed for blow press and casting operations, molds withstand up to 2,500 bar forming pressure and operating temperatures up to 350°C without deformation.

Quality Assurance:

Every P20 Blow Press Casting and Stamping Tooling Mold undergoes strict quality control at every stage. Raw materials are validated using spectrometry analysis for chemical composition. Precision measurements are verified with Mitutoyo CMM systems and Keyence 3D scanners to ensure dimensional accuracy within ±0.003 mm. Surface hardness is tested post-treatment (Rockwell & Vickers scales), while simulated production trials validate cycle consistency under industrial conditions. Our QA framework complies with ISO 9001:2015, IATF 16949, and global tooling standards, ensuring reliable, repeatable, and safe mold performance for professional applications.

Surface Treatment Options:

- Nitriding: Enhances hardness and wear resistance for longer mold life.

- Polishing & Mirror EDM Finish: Achieves smooth cavity surfaces for better part release.

- Chrome Plating: Provides corrosion resistance and reduced friction in high-cycle runs.

- PVD/CrN Coating: Improves surface hardness and thermal stability for demanding environments.

Our Factory:

Our advanced facility is equipped with 25–300 ton punch presses, multi-axis CNC machining centers, high-speed Mirror EDM and Wire EDM machines, and automated grinding/polishing systems to guarantee precision and repeatability. We integrate full in-house processes, including heat treatment, nitriding, plating, and surface finishing, enabling a complete one-stop mold manufacturing solution. With ISO 9001 and IATF 16949 certifications, every mold is produced under strict process control and rigorous testing. Supported by advanced inspection equipment such as 3D optical scanners, CMMs, and AOI systems, we ensure each mold exceeds industrial benchmarks for durability, consistency, and performance.