In today’s fast-paced manufacturing environment, customers expect shorter lead times, tighter tolerances, and consistently high-quality molded parts. At Toolingsun, we understand that achieving these goals is impossible without a well-engineered mold cooling system—the backbone of stable and efficient injection molding. Many manufacturers overlook cooling design when developing new tooling, but for experienced moldmakers like us, cooling strategy is one of the first—and most important—considerations during mold development.

If you are a purchasing manager, product engineer, or mold buyer seeking a high quality, one-stop service factory for injection molds, consider this guide your starting point. Our decades of hands-on experience in mold manufacturing and OEM service allow us to break down cooling concepts in a practical, production-oriented way.

Why Cooling Design Matters in Modern Injection Molding

Cooling is not simply a supporting function—it directly determines your production cost, part quality, and equipment utilization rate. In fact, cooling typically consumes 60–75% of the entire molding cycle, meaning even a small improvement yields significant financial gains.

When molten plastic fills the mold cavity, it must cool at a controlled, consistent rate to solidify into the intended shape. If cooling is uneven, slow, or poorly distributed, problems occur:

- Warping

- Sink marks

- Internal residual stresses

- Dimensional instability

- Poor surface finish

- Larger scrap rate

As a professional factory and OEM service provider, Toolingsun places heavy emphasis on cooling early in the design process. For us—and for top-tier suppliers across the industry—cooling is not an afterthought, but a core engineering discipline.

Fundamentals of Injection Mold Cooling

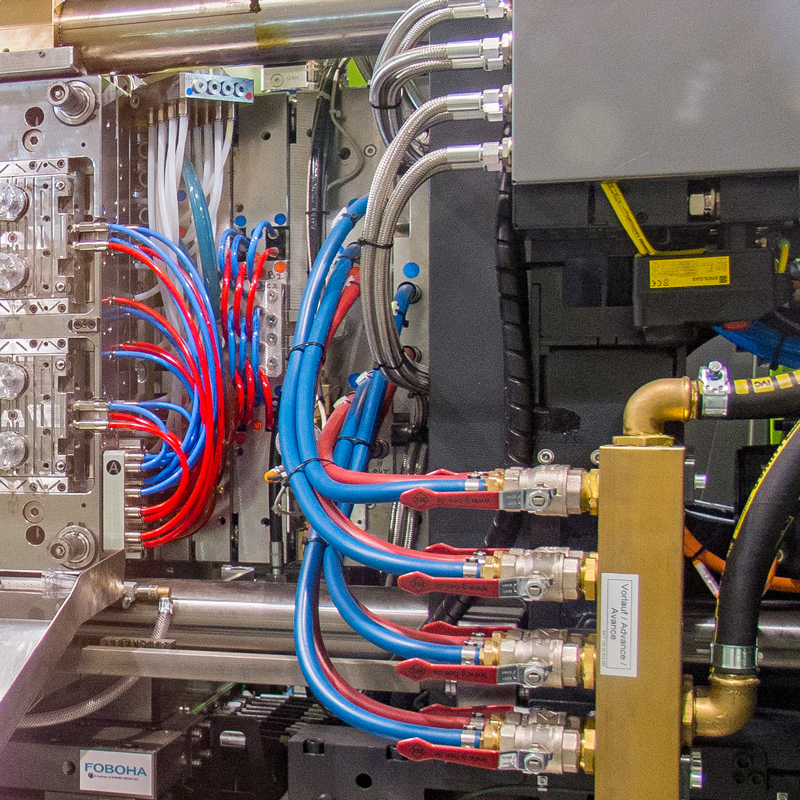

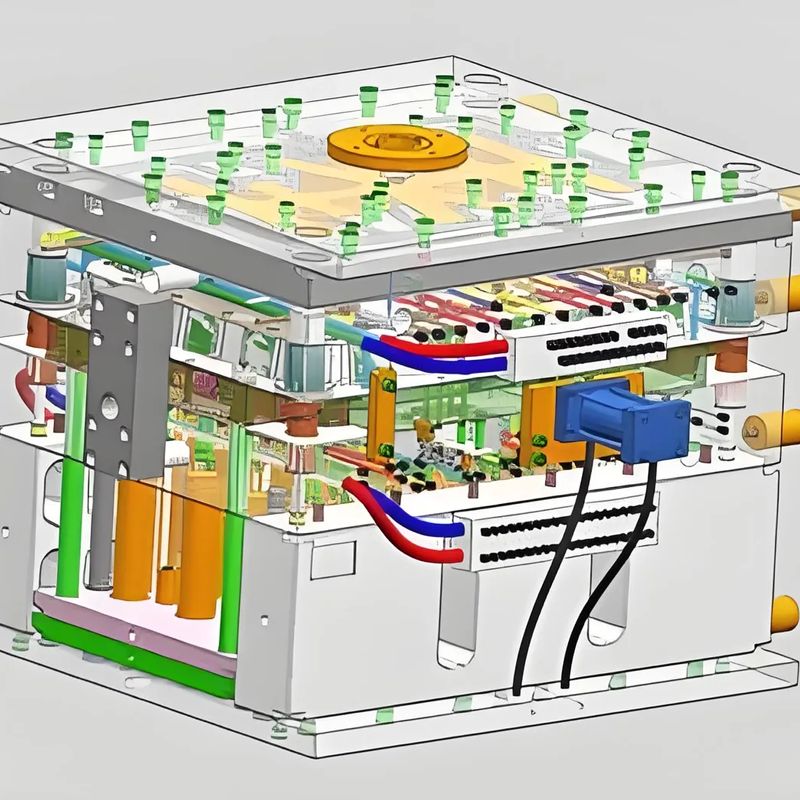

A mold cooling system consists of cooling channels (or cooling lines) that circulate a coolant—usually water—through the mold base and cavity inserts. The coolant absorbs heat from the molded plastic, then transfers it out of the mold through an external temperature control unit.

The efficiency of this system depends largely on:

- Coolant temperature

- Coolant flow rate

- Cooling channel diameter

- Channel spacing and placement

- Mold steel type and thermal conductivity

- Complexity and geometry of the part

At Toolingsun, we integrate all of these variables into our design philosophy to create molds with high quality thermal performance, optimized for long-term stability and productivity.

Air Cooling vs. Water Cooling: Choosing the Right Method

Air Cooling

Air cooling uses fans, blowers, or natural convection to remove heat. It is low-maintenance but provides much lower thermal conductivity.

Advantages

- Simple design

- No risk of rust or scale buildup

- Suitable for lightweight, low-volume, or micro molds

Limitations

- Extremely slow heat transfer

- Poor temperature control

- Not practical for high-volume production

Air cooling is rarely used in professional-grade molds unless geometric constraints prevent water channel installation.

Water Cooling

Water cooling is the industry standard due to its superior heat transfer rate and temperature stability.

A water cooling system commonly includes:

- Temperature control units (TCUs or thermolators)

- Water manifolds

- Filtration systems

- Additives such as biocides and corrosion inhibitors

Toolingsun, like many advanced manufacturers and suppliers, exclusively uses precision water-cooling channel layouts in most molds. Our engineering team uses simulation tools and years of expertise to achieve optimal channel spacing and coolant flow velocity.

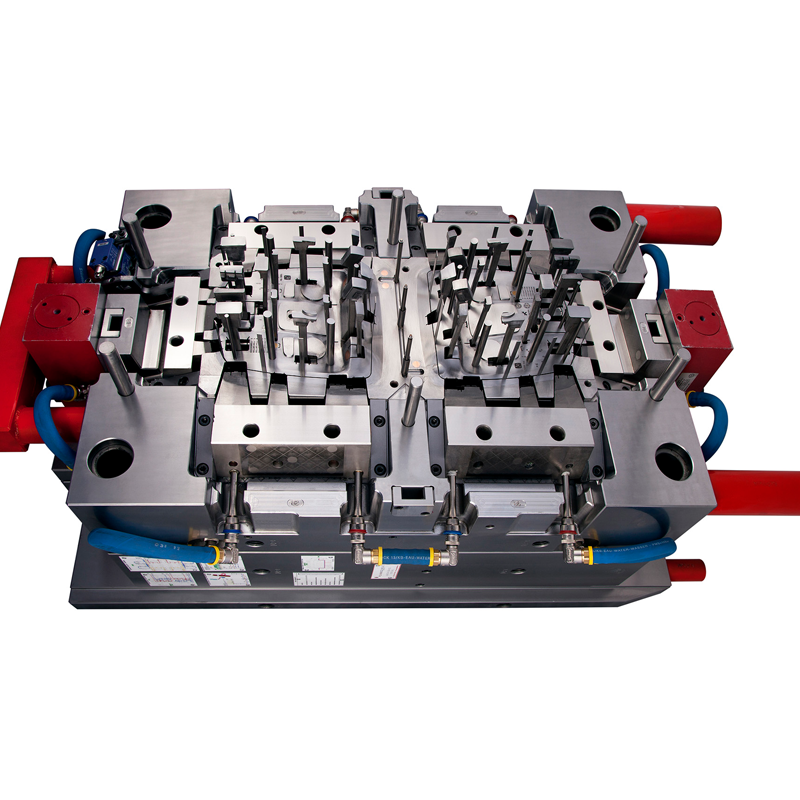

Types of Cooling Channels Used in Professional Moldmaking

1. Straight-Line Cooling

These are drilled channels that run in direct paths through the mold.

Pros

- Easy to manufacture

- Cost-effective

- Reliable

- Suitable for simple parts

Cons

- Cannot follow complex geometries

- Hot spots may develop where coolant cannot reach

This method is ideal for general-purpose molds and high-volume consumer products.

2. Conformal Cooling

Conformal channels are designed to follow the exact contour of the mold cavity. These are typically produced using 3D metal printing (DMLS or SLM).

Benefits

- Powerful reduction in cooling time

- Greatly improved dimensional stability

- More uniform part shrinkage

- Excellent for thick-wall or complex shapes

Although more expensive, Toolingsun’s one-stop service allows us to offer conformal-cooled inserts for customers who need extreme precision or cycle time reduction.

Cooling Aids: Enhancing Thermal Efficiency

Even with optimized channel layouts, certain areas—deep ribs, thick bosses, long cores—may require additional cooling tools. As a professional manufacturer and OEM service supplier, Toolingsun frequently uses the following:

Baffles

Metal plates inserted into channels that divide water flow into two paths.

Advantages

- Forces turbulent flow

- Improves heat transfer

- Ideal for large rectangular inserts

Bubblers

Hollow tubes allowing water to flow into narrow or deep areas.

Advantages

- Perfect for thin, deep cores

- Allows coolant access where drilling is impossible

Thermal Pins

Heat pipe–style inserts that rapidly transfer heat away from hot spots.

Advantages

- Extremely high thermal conductivity

- Great for high-temperature hotspots

Our engineering team chooses the right combination based on part geometry, resin type, and production volume.

Cooling Considerations for Different Mold Cores

Slender Cores (≤3 mm diameter)

- Conventional channels cannot be drilled

- Air cooling or copper-beryllium inserts are used

- Forced air jets are sometimes added during mold opening

Large Cores (≤40 mm diameter)

- Central cooling bores increase cooling coverage

- Copper alloys may be added to improve thermal conductivity

Cylindrical Cores

- Double-helix cooling is preferred

- Eliminates temperature gradients

- Improves roundness and dimensional accuracy

At Toolingsun, our cooling solutions are always tailored to your product requirements—an essential part of the one-stop service experience we provide.

Why Optimized Cooling Saves You Money

Cooling optimization is one of the highest-ROI improvements in injection molding. Benefits include:

- Shorter cycle times (10–40% reduction)

- Higher throughput without buying additional machines

- Lower scrap rates

- More consistent part quality

- Extended mold lifespan

- Reduced energy consumption

Our factory uses advanced simulation tools and decades of moldmaking experience to ensure every mold delivers the maximum cooling efficiency possible.

Conclusion:

A well-engineered cooling system is the difference between slow, inconsistent production and a fast, stable, and profitable molding operation. At Toolingsun, we take pride in providing high quality molds, built with precision, advanced cooling technology, and strict process control. Whether you need traditional cooling channels or cutting-edge conformal cooling, our experienced engineering team delivers tailored solutions as part of our OEM service and one-stop service manufacturing system.

If you’re looking for reliable mold manufacturers, suppliers, or a trusted factory partner who understands cooling optimization at the deepest technical level, we’re here to help.

👉 Contact Toolingsun today to discuss your project, request a design review, or get a customized quotation. Our team is ready to support your next high-performance injection mold with professional cooling expertise that delivers results.