Overview:

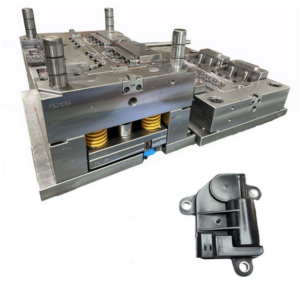

Our Custom Precision Plastic Injection Tooling Mold for New Energy Auto Parts is engineered to meet the stringent requirements of automotive-grade production. Crafted from premium, high-wear tool steels and utilizing advanced manufacturing technologies like high-speed CNC machining and precision EDM, these molds deliver the exceptional dimensional stability, superior surface finish, and long-term durability essential for critical EV components such as battery housings, charging connectors, and interior structural parts, all under a certified IATF 16949 quality system.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material (Core/Cavity) | Tool Steel (e.g., 1.2344/H13, 1.2083/S136, 1.2738/P20+Ni), Hardened Steels |

| Runner System | High-Performance Hot Runner (Valve Gate for precision) / Cold Runner |

| Mold Design Software | UG NX, CATIA, Moldflow (for simulation) |

| Sample | T0 Mold Trial Samples with CMM Report |

| Certification | ISO9001, IATF 16949 |

| Packaging | Reinforced Wooden Case, Weatherproofed |

| MOQ | 1 Set |

| Lead Time | 40-60 Days (Complexity Dependent) |

Surface Treatment & Enhancement Options:

-

Nitriding (Gas/Plasma): Significantly increases surface hardness and wear resistance, reduces sticking, and extends mold life for processing abrasive engineered plastics (e.g., glass-filled materials) common in automotive parts.

-

Hard Chromium Plating: Provides an extremely hard, low-friction surface that improves part release and protects against corrosion from certain high-temperature engineering plastics.

-

High-Gloss Mirror Polishing (SPI A1/A2): Achieves Class-A optical surfaces required for visible interior or exterior components, ensuring flawless aesthetic quality.

-

Specialized Coatings (PVD, DLC): Titanium-based (TiN, TiCN) or Diamond-Like Carbon coatings offer ultra-high hardness and superior anti-stick properties, ideal for challenging resins and maximum longevity in high-volume cycles.

Quality Assurance:

Our quality assurance for automotive molds is an exhaustive, phase-gated process aligned with IATF 16949 standards. It begins with a comprehensive DFM and Moldflow analysis to prevent defects. During machining, in-process CMM inspections validate core/cavity geometries. Post-heat treatment, hardness is verified across critical sections. The final and most critical phase is the mold trial (T0, T1…), where we produce sample parts, conduct full-dimensional CMM inspection, perform functional and assembly tests, and provide detailed reports. This ensures the mold not only meets print specifications but also produces parts that function perfectly in the final vehicle assembly.

Why Choose Us?

-

Automotive-Grade Engineering Expertise: We specialize in molds for the automotive sector, designing for high cavitation, automatic operation, and integration with robotics, ensuring reliability for millions of cycles in a demanding production environment.

-

Advanced Simulation & Precision Manufacturing: We utilize Moldflow simulation to optimize cooling and filling, preventing warpage and sink marks. Our high-precision machining (5-axis CNC, Mirror EDM) guarantees the tight tolerances (±0.005mm) required for part fit and function.

-

Full Compliance & Traceability: Our IATF 16949 certified system ensures strict process control, full material certification, and complete traceability from steel batch to finished mold, meeting all automotive customer PPAP (Production Part Approval Process) requirements.

-

Proven Track Record in New Energy Sector: We have direct experience manufacturing molds for critical EV components, understanding the unique material, safety, and performance demands of battery systems, charging infrastructure, and lightweight structural parts.

Factory Show:

Our mold manufacturing facility is equipped with the specialized machinery required for automotive tooling, including 5-axis high-speed CNC machining centers, large-capacity CNC EDM machines, and deep-hole drilling for conformal cooling channels. We have dedicated heat treatment ovens with precise atmosphere control and an in-house laser welding station for mold repair and texturing. Quality is verified in our temperature-controlled metrology lab using bridge-type CMMs, portable 3D scanners, and surface gloss/roughness testers. Operating under an IATF 16949 certified management system, our entire process—from design to final tryout—is focused on delivering robust, precision molds that meet the zero-defect expectations of the global new energy automotive industry.