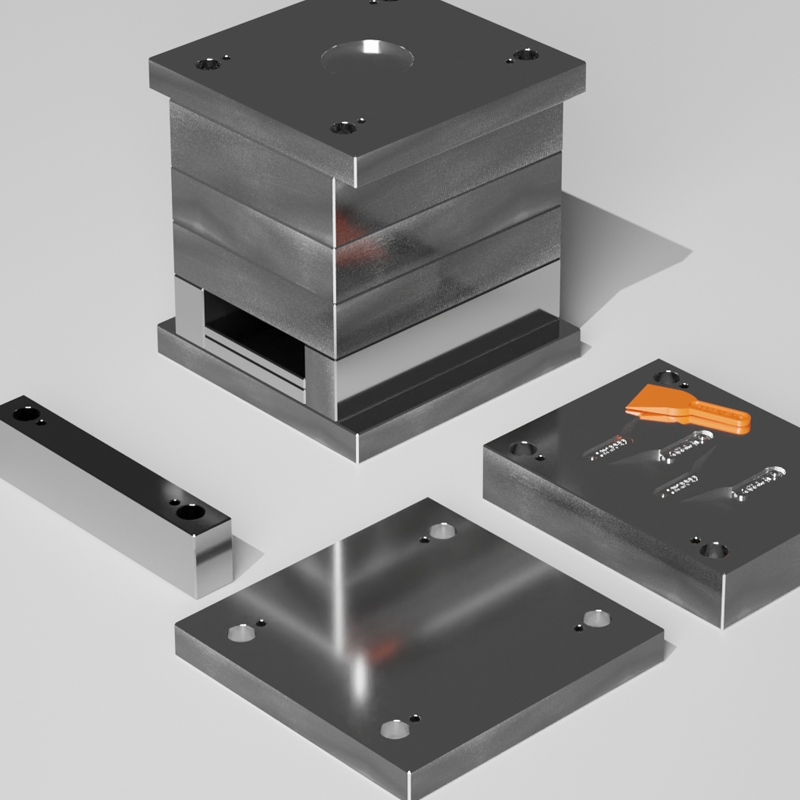

Success in the injection molding industry is not just about having the best equipment or the latest technology—though those certainly help. The real key to achieving manufacturing excellence lies in the alignment between injection molders and toolmakers. At Toolingsun, we understand that the true measure of success is how well these two vital players in […]