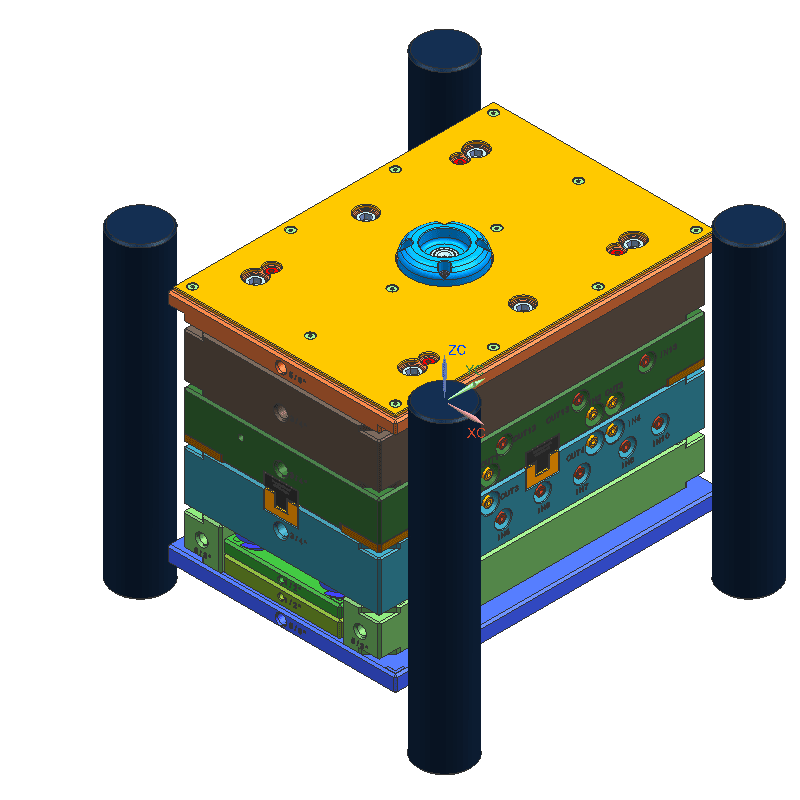

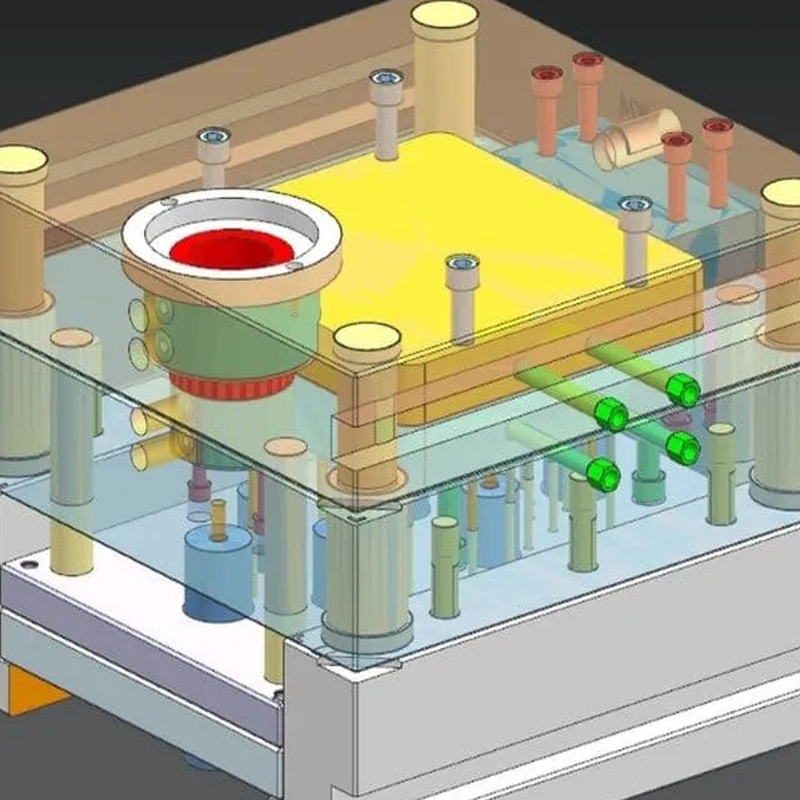

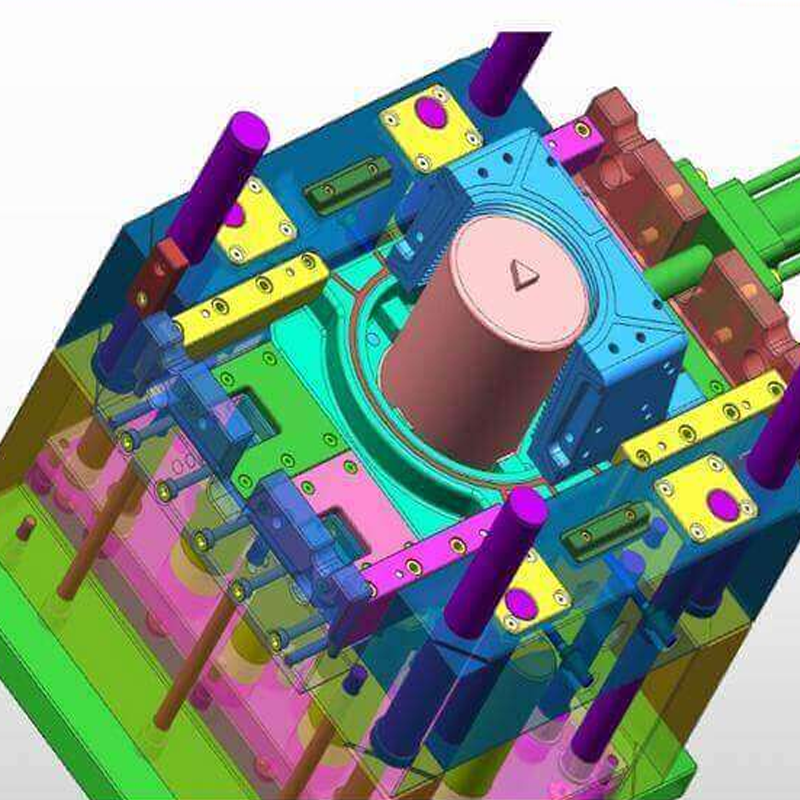

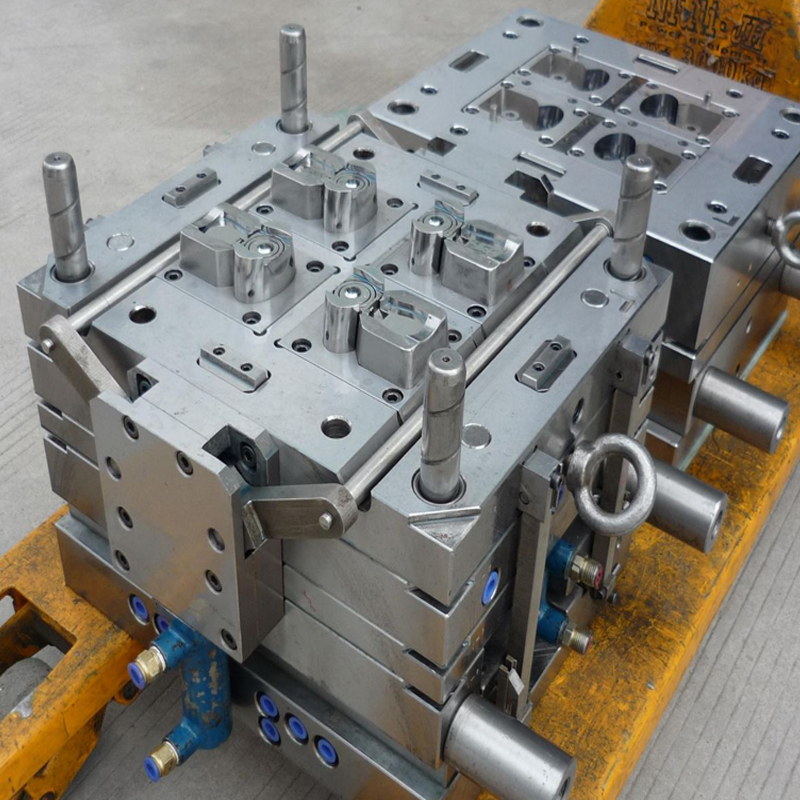

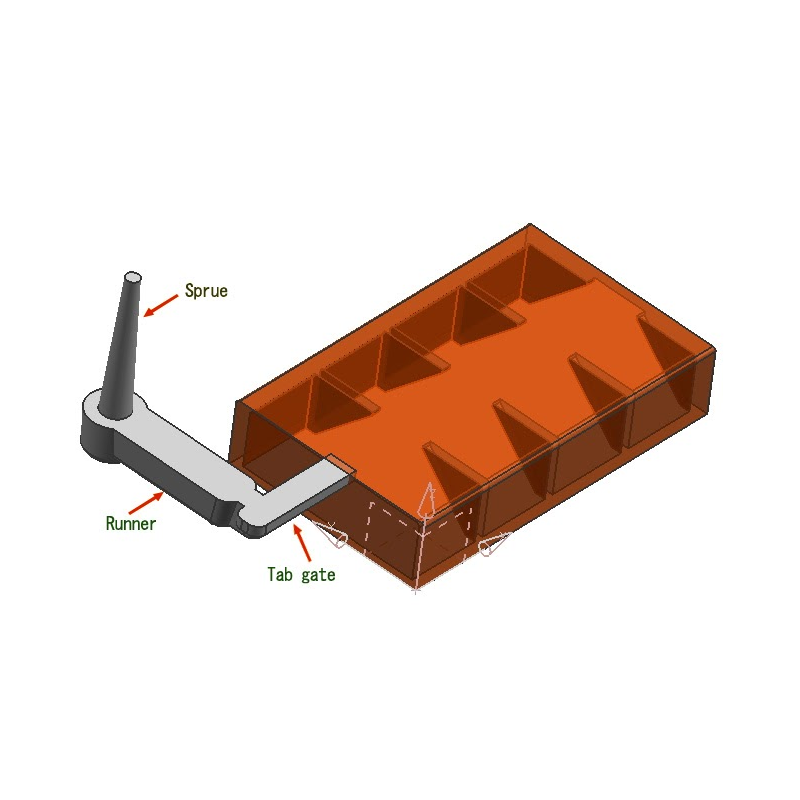

At Toolingsun, we understand the crucial role that Design for Manufacturing (DFM) plays in achieving production efficiency, cost reduction, and high-quality outcomes in plastic injection molding. No matter the size of the project, incorporating DFM principles from the earliest stages can significantly improve the overall design and manufacturing process. Our expertise in DFM enables us […]