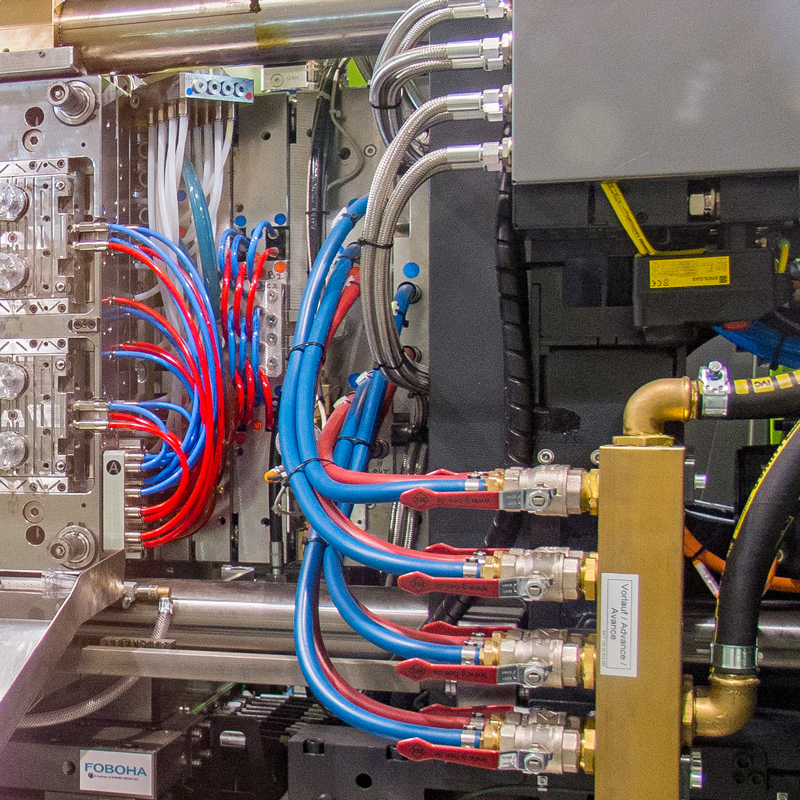

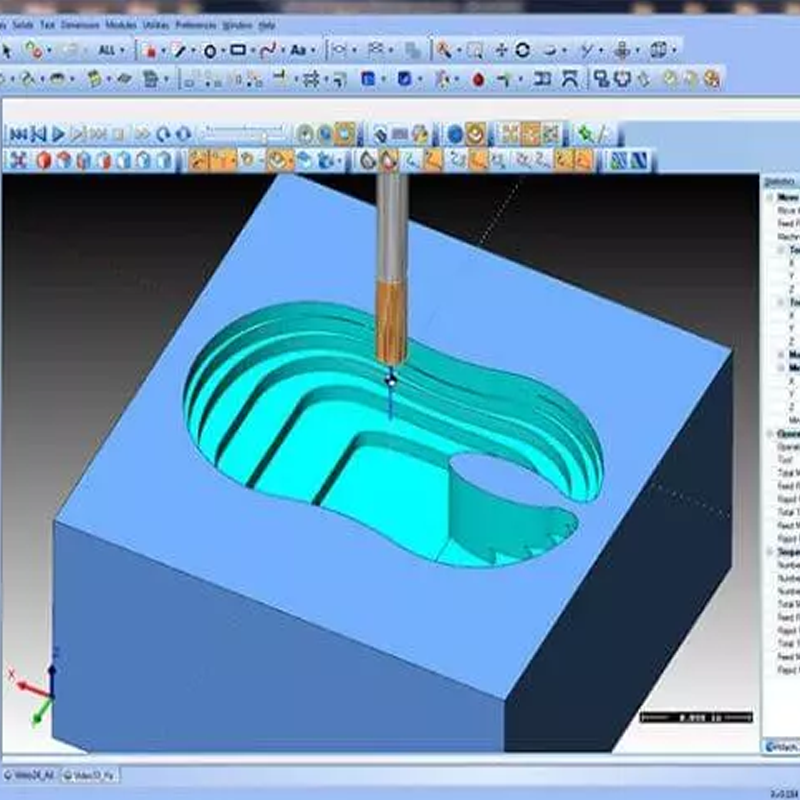

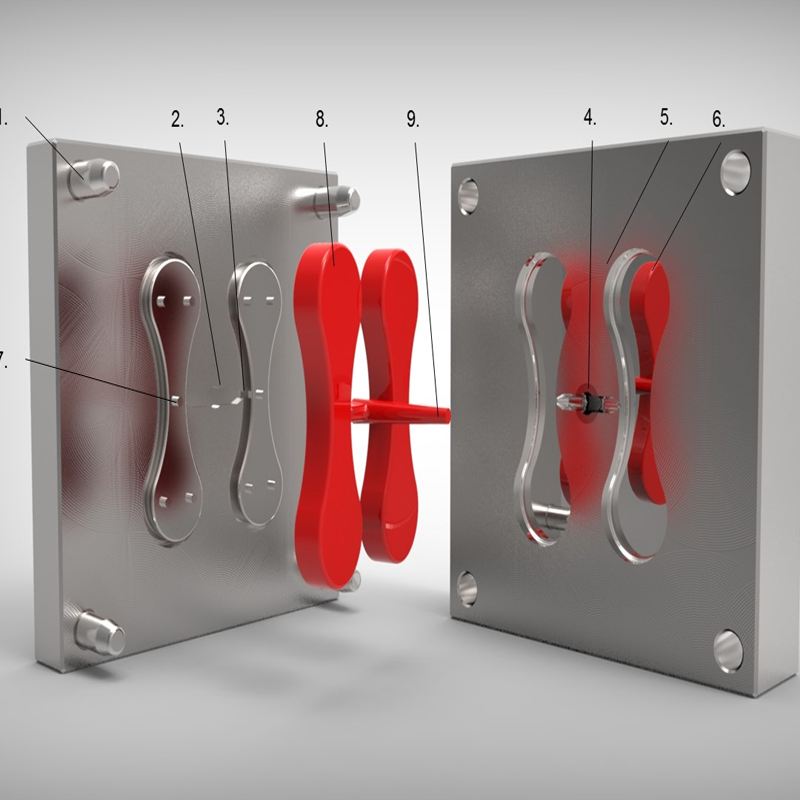

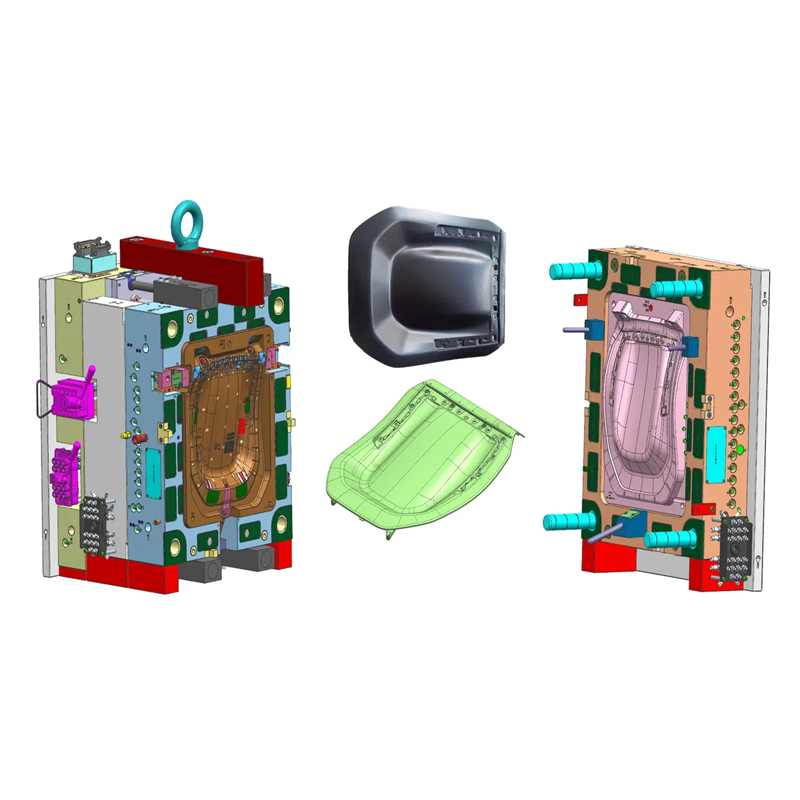

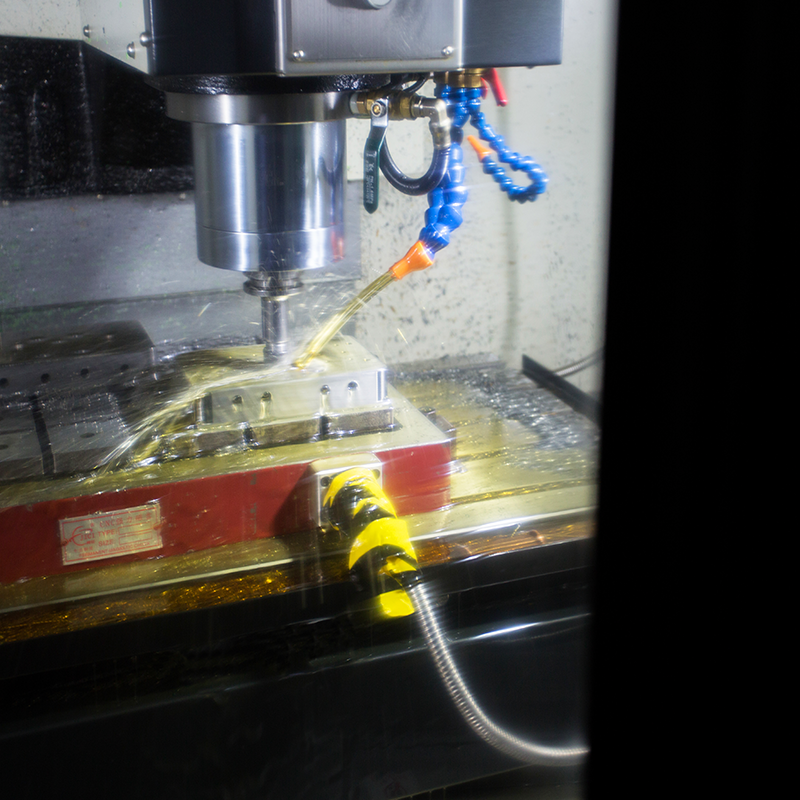

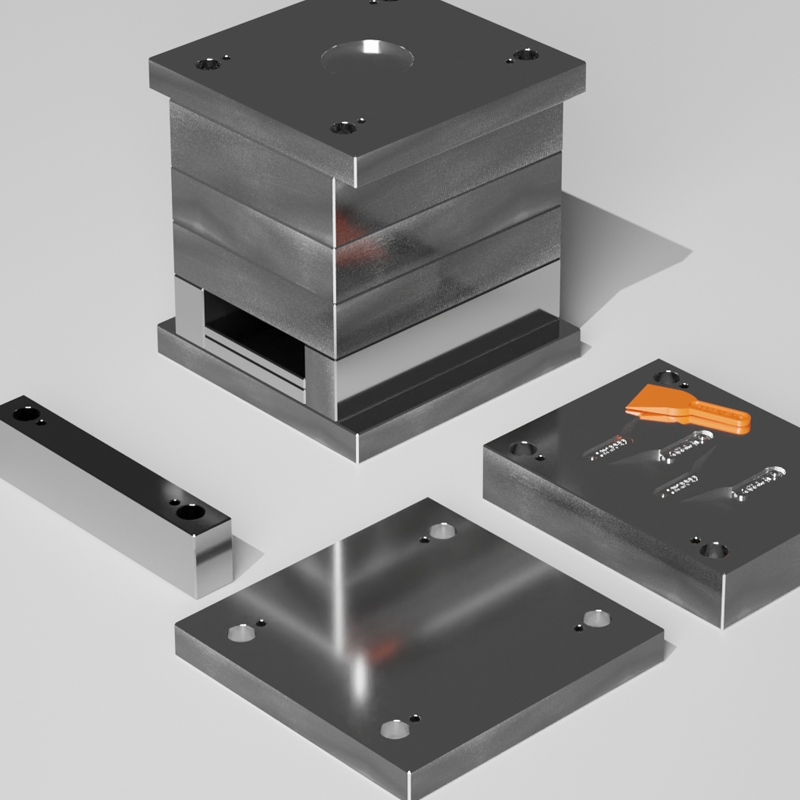

In today’s fast-paced manufacturing environment, customers expect shorter lead times, tighter tolerances, and consistently high-quality molded parts. At Toolingsun, we understand that achieving these goals is impossible without a well-engineered mold cooling system—the backbone of stable and efficient injection molding. Many manufacturers overlook cooling design when developing new tooling, but for experienced moldmakers like us, […]