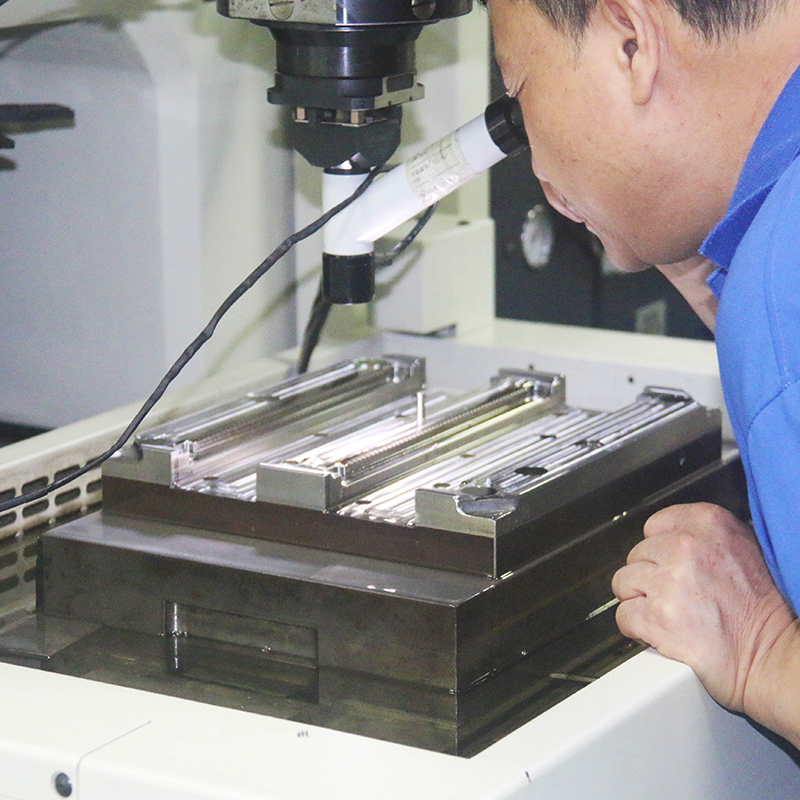

At Toolingsun, a precision-focused manufacturer and factory serving global OEMs and suppliers, we rely on Coordinate Measuring Machine (CMM) inspection every day to guarantee part accuracy and traceability. Whether you’re validating a new prototype or running final inspection on production lots, CMM inspection provides the reliable, traceable measurements engineers need to control quality and accelerate time […]