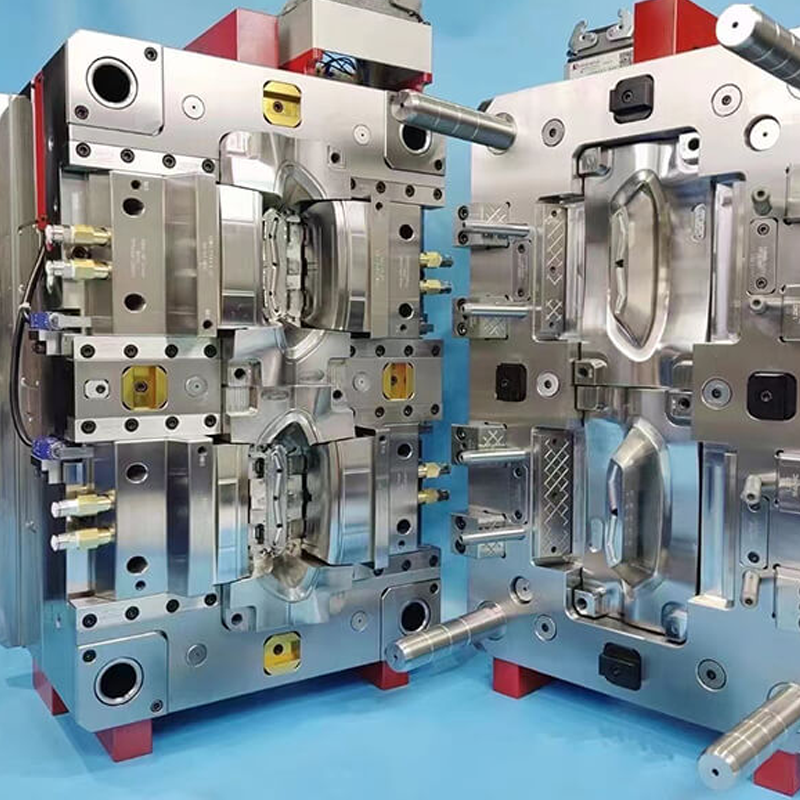

Thanks — great question. If you’ve ever wondered what happens after a part leaves the injection mold, this guide walks you through the practical post-processing steps manufacturers use to turn molded components into finished, assembly-ready parts. At Toolingsun, we integrate these downstream processes into our factory workflows so OEMs get a true one-stop service: design for manufacturability, molding, finishing, testing and packing — all under a single quality system. Below is a professional, production-focused overview you can use to plan for cost, lead time, and part performance.

Why post-processing matters

Injection molding is excellent at producing net-shape geometry quickly, but parts rarely come out of the tool fully finished for end use. Post-processing removes unwanted material (gates, flash), adds functional or decorative surfaces (paint, powder coat, laser marks), and assembles components (heat staking, ultrasonic welding). Deciding which operations to apply early in the design stage lets you optimize material choice, tooling complexity, and unit cost — which is why our engineering teams at Toolingsun collaborate with customers during DFM reviews to define the best post-processing plan.

The six core post-processing operations

1) Gate trimming (degating) and flash removal

What it is: Removing gate vestiges and flash left where the runner meets the cavity or along parting lines.

Why it matters: Ensures appearance, tolerance, and sealing surfaces; prevents assembly interference.

How it’s done:

- Manual trimming — hand tools for prototypes or very low volumes.

- Automated trimming — robotic or machine-mounted cutters and fixtures for high volumes and consistency.

- In-mold degating — hot runner or shear gate designs that minimize secondary work.

Design tip: Specify accessible gate locations during parting-line planning to reduce secondary rework and preserve cosmetic faces.

2) Painting and coating

What it is: Applying decorative or protective coatings including solvent/UV spray, powder coat, and specialty functional coatings (EMI shielding, soft-touch).

Why it matters: Enables premium surface looks and functionality that are difficult or costly to achieve via resin selection alone.

Key steps: surface cleaning, optional plasma treatment for low-energy plastics (PP/PE), primer, top coat, and curing.

Production note: Powder coating and UV curing can be more environmentally friendly and faster than solvent painting for medium to high volumes.

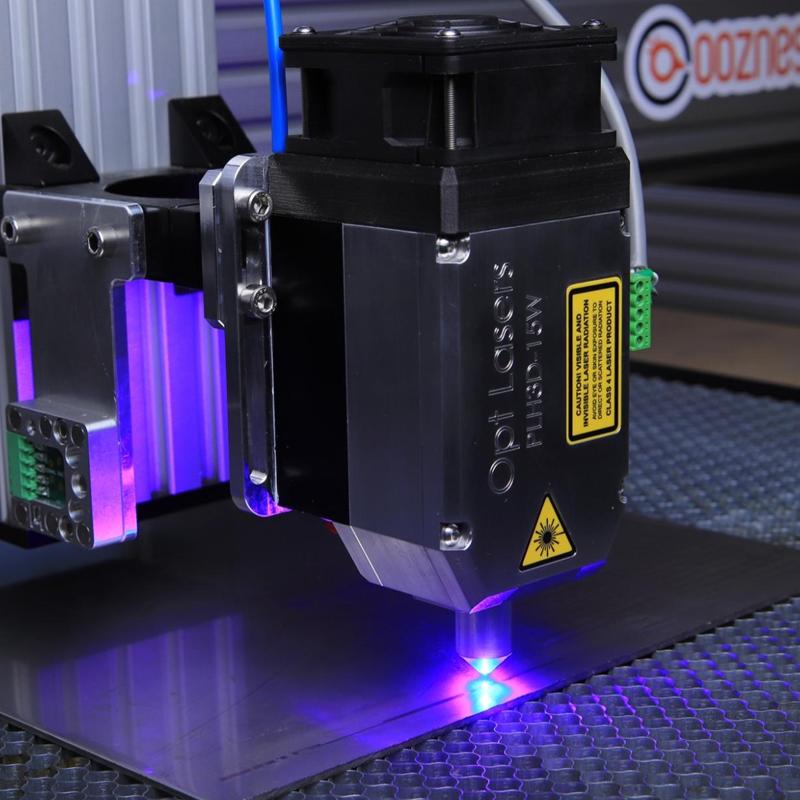

3) Laser marking

What it is: Non-contact, permanent marking of part IDs, barcodes, logos, or traceability data using a laser.

Why it matters: High resolution, durable marks for regulatory tracking and anti-counterfeit needs.

Methods & effects: color change (carbonization), foaming (raised light mark), or ablation (etch).

Material advice: Some polymers need additives or pigments to achieve good contrast — discuss material selection with your suppliers early.

4) Pad printing (and screen/silk printing)

What it is: Transfer of graphics onto 3D surfaces using a silicone pad (pad printing) or mesh screen (screen printing).

Why it matters: Ideal for multicolor logos, instrument faces, and controls on curved or irregular surfaces.

Best practice: Confirm flatness radii and print registers in the drawing; design reliefs to act as printing windows where possible.

5) Heat staking (thermoplastic staking)

What it is: Creating a permanent mechanical capture by melting and reforming a thermoplastic boss to retain a metal insert or other part.

Why it matters: Securely fixes nuts, standoffs, and components without adhesives or secondary fasteners.

Process control: Correct stake tool temperature, dwell time, and forging shape are critical to avoid over-flow or weak heads.

6) Ultrasonic welding

What it is: Joining two thermoplastic components with high-frequency vibration to generate localized heat and fuse the interface.

Why it matters: Fast, clean, solvent-free assembly method ideal for housings, medical devices, and sealed enclosures.

Design tip: Add energy directors (small triangular ribs) at the joint and plan fixture location to ensure consistent weld strength.

Planning: integrate post-processing in product development

Post-processing should be part of the earliest product decisions. Key planning actions we recommend at Toolingsun:

- DFM review for finishing — specify which faces need cosmetic quality, where marks/logos will go, and whether in-mold labeling (IML) or secondary printing is preferred.

- Material selection with finishing in mind — pigments, fillers and polymer choice affect paint adhesion and laserability.

- Tooling features — add register bosses, energy directors, and gate positions that minimize secondary operations.

- Cycle time & throughput — map process flow (molding → trim → paint → cure → assembly) so takt rates match demand.

- QA planning — define inspections (dimensional, adhesion, hardness, mark contrast) and sampling frequency up front.

Typical decision criteria: paint vs pigment vs in-mold finish

- Color through the material (pigmented resin): lowest per-part cost at very high volumes and resilient to scratches.

- Painting/coating: best for metallic effects, soft-touch, or color variety without new tooling. Preferable when total volumes don’t justify expensive pigment tooling.

- In-mold labeling (IML) or overmolding: highest initial tool cost but delivers premium, scratch-resistant finishes if volumes and design justify it.

Frequently asked practical questions

Q — Will post-processing always increase unit cost?

Yes — added steps mean added time and labor/ equipment. But smart use of post processes can be more economical than expensive resins, complex tooling, or rework down the line.

Q — Can every plastic be laser-marked?

Not automatically. Success depends on polymer chemistry and dye load. Engineering plastics like ABS, PC, and some nylons mark well; polyolefins often require surface additives or pre-treatment.

Q — How to choose between heat staking and ultrasonic welding?

Use heat staking when inserting fasteners or joining dissimilar materials (metal inserts). Use ultrasonic welding for fast, clean plastic-to-plastic assembly with short cycle times.

Q — How important is surface prep before painting?

Critical — inadequate cleaning or lack of plasma/Corona treatment on low-energy plastics leads to poor adhesion and early coating failure.

Quality, traceability and supplier coordination

As an OEM service provider and manufacturer, Toolingsun emphasizes traceability and documented process control. For each project we:

- maintain incoming material certificates from suppliers;

- log process parameters for molding, painting, and welding;

- perform incoming and inline QC checks (adhesion tests, durometer, dimensional checks, visual accept/reject criteria);

- provide serialization/marking options for full traceability.

This approach reduces surprises during scale-up and ensures the “finished” part you receive meets the same spec as your initial approval sample.

Practical checklist for customers before tooling approval

- Identify critical cosmetic surfaces and tolerance-critical features.

- State required markings (logos, UID, 2D codes) and whether they must be laser permanent.

- Decide if you prefer in-mold or post-mold decoration.

- Confirm whether inserts will be installed (heat stake) and how many assembly cycles the part must withstand.

- Ask your supplier for a full process flow diagram and Cpk data for critical steps.

Conclusion

If you’re evaluating suppliers, the difference between a mold-only vendor and a full one-stop service provider shows up during post-processing. At Toolingsun, we deliver OEM service through tightly integrated workflows: engineering, tooling, molding, finishing and assembly — backed by supplier networks and factory QA. That means fewer handoffs, clearer accountability, and faster time to market.

If you’d like, we can review a sample CAD file and outline the post-processing flows we’d apply (trimming, marking, paint/coat options, and assembly) along with cost and lead-time estimates. Send the file to our engineering team and we’ll prepare an actionable plan that aligns with your quality and budget targets.