Plastic containers are integral components used across various industries, essential in applications ranging from packaging and storage to consumer goods. These versatile products have become the preferred choice for packaging solutions, offering advantages over traditional materials like glass and metal. With their lightweight, durable, and cost-effective nature, plastic containers meet the diverse needs of modern consumers, from food and beverage packaging to household storage and industrial transport solutions.

As demand for sustainable and innovative packaging continues to rise, understanding the principles behind plastic container mold design and manufacturing is becoming increasingly crucial. In this blog, we will explore the key stages involved in the development of plastic container molds, from conceptual design to the precision fabrication processes that shape the final product. By examining these techniques, we will highlight how the design of plastic container molds influences both product performance and production efficiency, offering valuable insights for businesses seeking high-quality, customized solutions.

At Toolingsun, we specialize in providing tailored solutions for plastic container molding. Our experienced team ensures precision and efficiency in every project we undertake, helping you achieve the best results for your manufacturing needs. If you’re considering a plastic container molding project, read on to learn about the techniques involved, and discover how we can assist in bringing your ideas to life.

What Is a Plastic Container Mold?

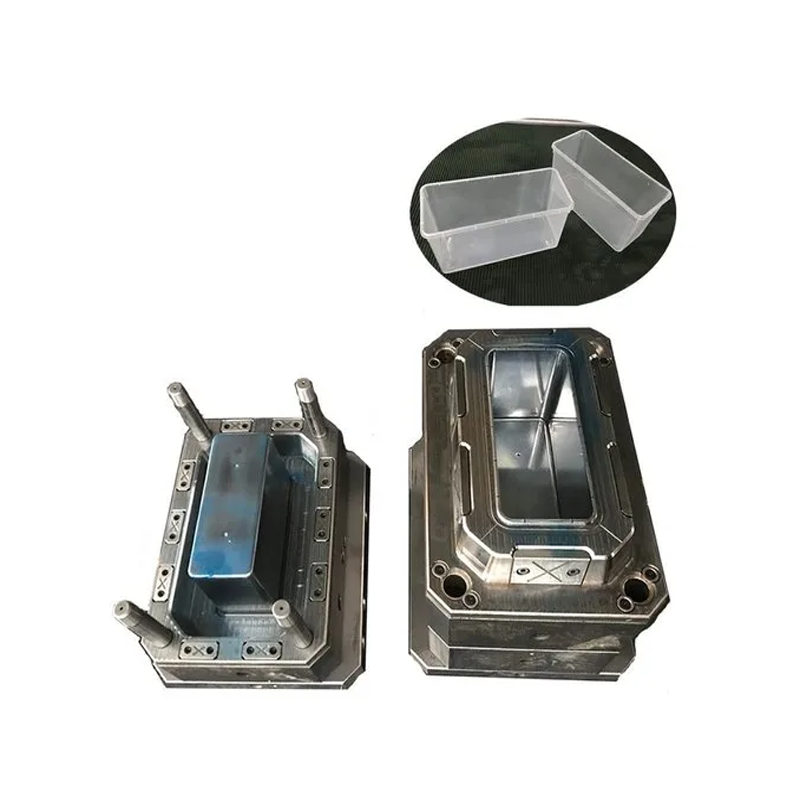

A plastic container mold is a specialized tool used in the manufacturing of plastic containers, typically through injection molding processes. These molds are crafted from high-strength materials such as steel or aluminum, and they consist of one or more cavities that define the container’s final shape and structure. During injection molding, molten plastic is injected into the mold, cooled, and solidified, resulting in a finished container that meets specific dimensions and intended functionality.

The mold serves as the foundation of the manufacturing process, converting raw plastic materials into practical, everyday products. From food containers to industrial storage solutions, these molds play a vital role in mass production, ensuring consistency, quality, and durability across all products.

Key Characteristics of Plastic Container Molds

Several features contribute to the quality and effectiveness of plastic container molds. These characteristics depend on the mold’s design, material selection, and manufacturing techniques, all of which are tailored to meet production requirements for different container types. Some of the key characteristics include:

– Durability and Strength: Molds are designed to withstand the high pressures and temperatures involved in the injection molding process. Materials such as steel and aluminum are chosen for their durability, ensuring the mold’s longevity and the consistent production of containers. This durability extends to the containers produced, many of which are dishwasher safe, offering added convenience for end-users.

– Versatility and Flexibility: Plastic container molds are adaptable to various designs and sizes, enabling the customization of containers based on specific needs. Whether producing food-grade containers, medical packaging, or industrial storage solutions, these molds can be tailored to meet the requirements of different industries, ensuring versatility across applications.

– Efficient Production: One of the most significant advantages of plastic container molds is their ability to facilitate high-efficiency mass production. The injection molding cycle is relatively quick, often taking only seconds to a few minutes, allowing for rapid production and cost-effective manufacturing at large scales.

Types of Plastic Container Molds

Plastic container molds can be categorized based on the molding technique used, with each process offering distinct advantages depending on the application. The primary types of plastic container molds include:

– Injection Molds: The most commonly used molds for plastic containers, especially those requiring precise and complex shapes, such as beverage bottle caps or food packaging. Injection molds offer high production efficiency and ensure consistent results across large production runs, making them ideal for mass production.

– Blow Molds: Blow molding is used to create hollow containers, such as plastic bottles and tanks, by inflating a heated plastic parison inside a mold. Techniques such as extrusion blow molding, injection blow molding, and stretch blow molding are used in this process, which is perfect for producing lightweight containers with uniform wall thickness.

– Extrusion Molds: Extrusion molding is utilized to produce continuous shapes, such as pipes, rods, and films. In this process, melted plastic is forced through a die to form long, continuous products. This technique is particularly suitable for the high-volume production of plastic containers that require strength and uniformity.

Key Design Considerations for Plastic Container Molds

The success of a plastic container mold depends on several design considerations that directly affect the production process, mold durability, and the quality of the final product. These factors include:

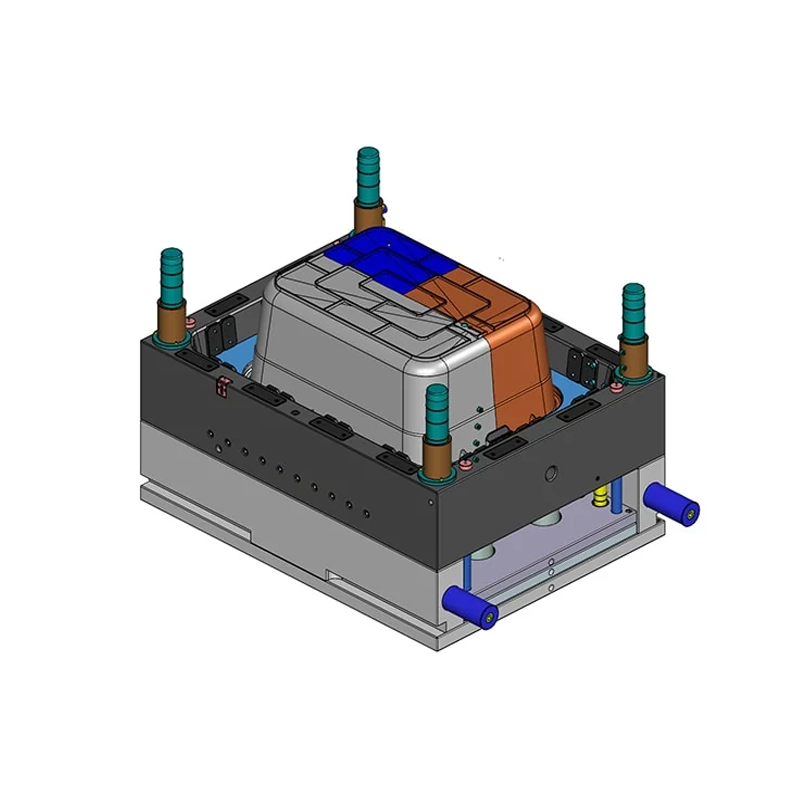

– Geometry and Complexity: The design of the container directly impacts the mold design. Simple shapes may require less intricate mold designs, while more complex containers with features such as sharp edges, snap-fit lids, or recessed handles demand specialized molds with undercuts and side actions.

– Cooling System Design: Effective cooling is crucial to ensure consistent product quality and reduce cycle time. Improper cooling can lead to defects such as warping or internal stresses. A well-designed cooling system uses high-conductivity materials, such as beryllium copper inserts, to improve heat transfer in high-temperature areas.

– Ejection Mechanism: The ejection system ensures that molded containers are released from the mold without damage. Strategically placed ejector pins are used to push the container out smoothly, preventing marks or damage to key areas. The placement and number of ejector pins are determined based on the container’s size and material properties.

– Venting: Proper venting is necessary to allow air to escape during the injection process, preventing air pockets that can result in defects such as burn marks or incomplete filling. Well-placed vents ensure that air is effectively displaced, ensuring a flawless product.

Manufacturing an Injection Mold for Plastic Containers

The process of creating an injection mold for plastic containers involves several crucial steps, each requiring precision and expertise:

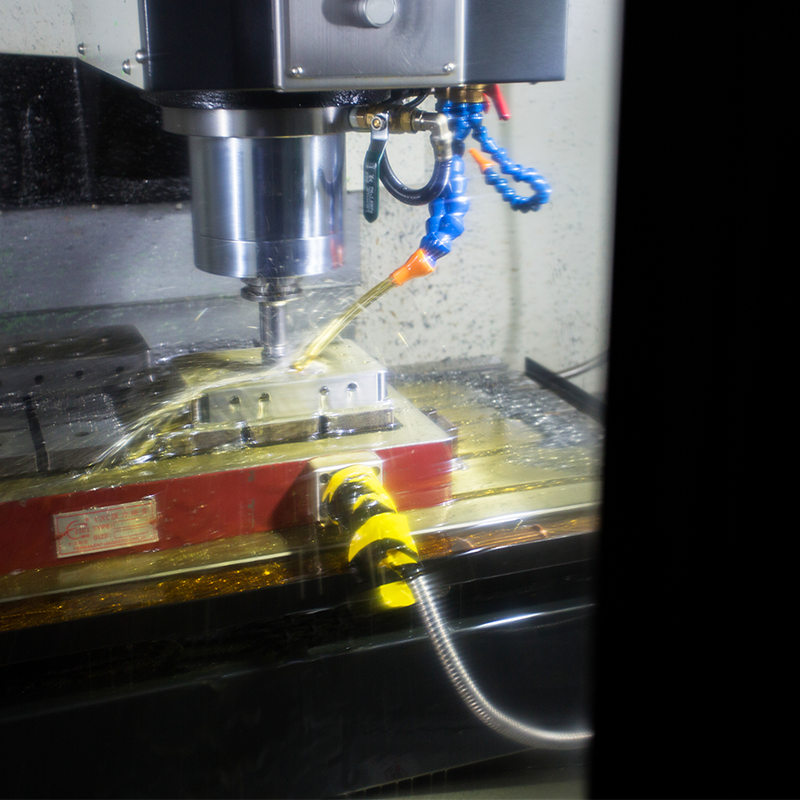

- Selecting Mold Material: The right material is critical for mold durability and performance. Steel, particularly P20 and H13, is commonly used for its toughness and heat resistance, while aluminum is preferred for prototype molds due to its ease of machining.

- Fabricating the Mold: CNC milling machines are used to precisely cut the mold base, cavities, and cores. For intricate details, electrical discharge machining (EDM) is used. The cavity and core halves are then aligned using guide pins to ensure precision.

- Finishing and Surface Treatment: Once the mold is fabricated, the cavity surfaces are smoothed and polished to achieve the desired finish. Surface treatments such as chrome plating are applied to enhance wear resistance and improve the mold’s overall aesthetic appeal.

- Testing and Refining the Mold: After fabrication, the mold undergoes testing by injecting plastic to produce sample containers. Any defects or issues, such as warping or incomplete filling, are addressed by modifying the mold, adjusting cooling channels, vents, or ejector pins as needed.

Applications of Plastic Container Molds

Plastic container molds are widely used in various industries to manufacture functional containers suited for specific applications. Key areas of use include:

– Food and Beverage Packaging: Molds are used to produce food-grade containers such as beverage bottles, yogurt cups, and food storage boxes. These molds must meet stringent hygiene standards and produce lightweight, durable, and recyclable products.

– Industrial and Logistics Storage: Large containers, such as pallets and bins, are molded for strength and load-bearing capabilities, ensuring their suitability for chemical transport, warehousing, and logistics.

– Household Goods: Plastic molds are also used to create common household products like storage bins, trash cans, and kitchen tools.

– Pharmaceutical and Healthcare: Molds are used to produce medical-grade containers, including medicine bottles and reagent storage boxes, which must meet strict safety and sterility standards.

The Future of Plastic Container Mold Technology

As industries continue to prioritize sustainability and customization, plastic container mold technology is evolving. Emerging trends include:

– Sustainable Materials: The use of biodegradable plastics and recycled materials is prompting mold development to accommodate these new materials without sacrificing product quality.

– Smart Molds: The integration of sensors into molds allows for real-time monitoring of temperature, pressure, and cycle times, improving production efficiency and reducing downtime.

– Additive Manufacturing: 3D printing technology is accelerating the prototyping process, enabling faster iterations and greater flexibility in mold design.

Conclusion

Plastic container molds are a vital part of the manufacturing process, influencing the quality, efficiency, and sustainability of the products they create. From material selection to precise fabrication techniques, every aspect of mold design plays a crucial role in ensuring the success of a molding project. At Toolingsun, we are committed to delivering high-performance, cost-effective mold solutions tailored to your unique requirements. Whether you’re seeking custom plastic container molds or expert guidance on your next project, our experienced team is here to assist you. Contact us today for a competitive quote and learn how we can help you achieve your manufacturing goals!