When it comes to injection molding, few elements are as critical to the success of your product as tooling. From design to materials selection, tooling determines the quality, cost-effectiveness, and longevity of your molded parts. However, obtaining an accurate and comprehensive tooling quote can be tricky, especially with the growing pressures of tariffs and the evolving global manufacturing landscape.

At Toolingsun, we understand that the tooling quote lays the foundation for a successful injection molding project. As a one-stop service provider, we aim to offer our clients a seamless experience, from design for manufacturability (DFM) to custom tooling and production. Our expertise in high-quality tooling manufacturing ensures that all your requirements are met, leading to parts that perform flawlessly and are delivered on time.

Let’s dive into five crucial tips for securing a precise and reliable tooling quote.

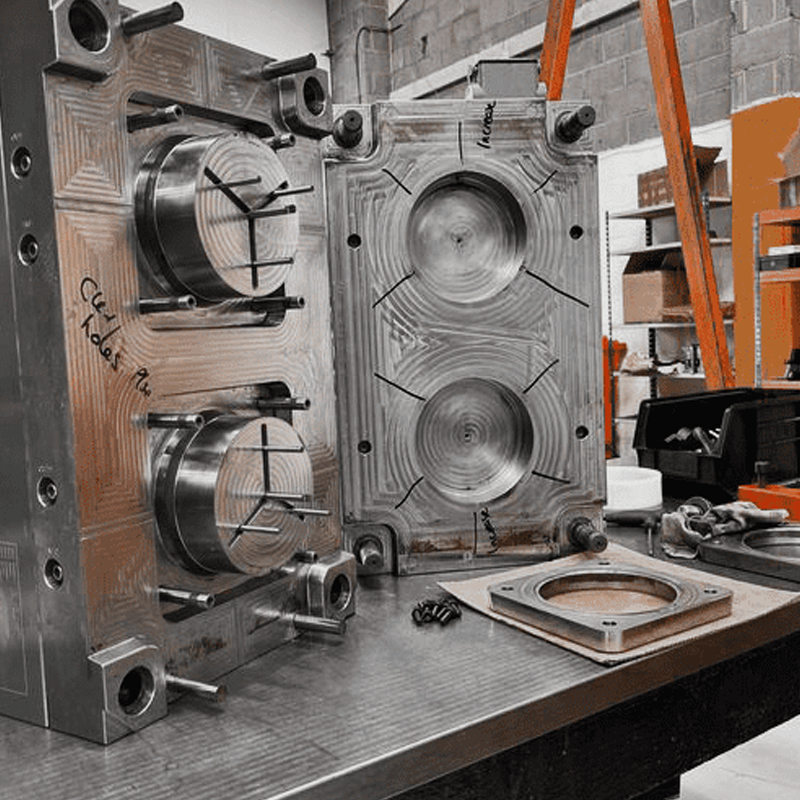

1. Vet the Appropriate Cavitation for Your Project

One of the first considerations when obtaining a tooling quote is the number of cavities needed for your part. This decision goes beyond just cost—it has long-term implications on production speed, tooling cost, and part quality.

- Single-Cavity Tools: Fewer cavities result in a lower upfront tooling cost, but each part costs more to produce. These tools are simpler and easier to maintain, making them a good choice for lower-volume production runs.

- Multi-Cavity Tools: Multiple cavities can dramatically increase the speed of production by molding several parts at once, but they come with a higher initial tooling cost. They can be a great choice for high-volume production and cost-efficiency in the long run.

When evaluating cavitation, it’s essential to discuss your needs with your injection molding partner. At Toolingsun, we offer custom solutions based on your production requirements, ensuring that you strike the right balance between tooling costs, speed, and product quality.

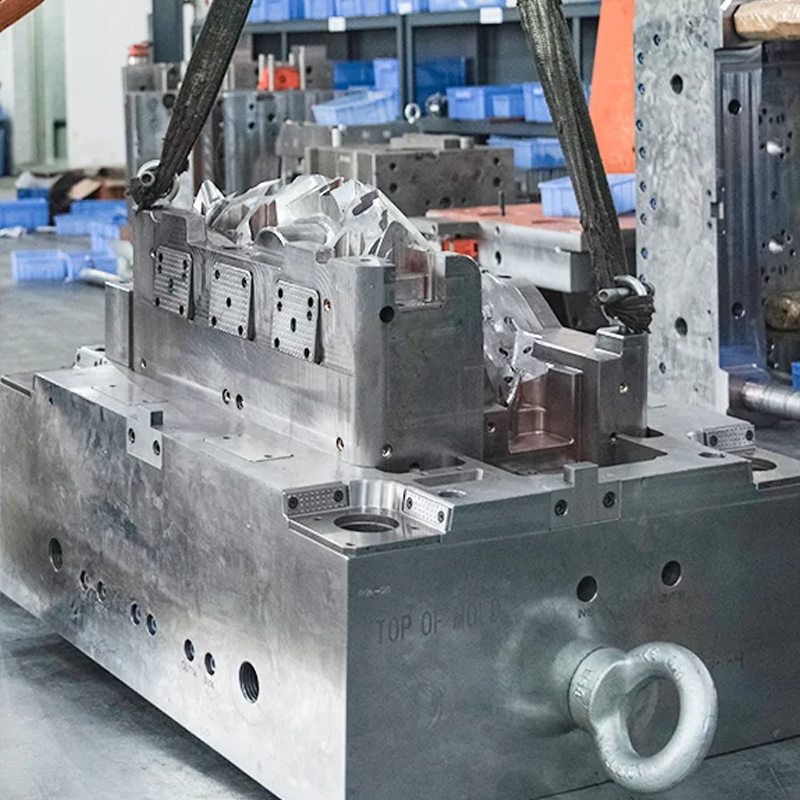

2. Clearly Identify the Materials Used for Tooling Construction

Tool materials significantly influence both the quality and longevity of your injection mold. The type of material you choose for your tooling—whether it’s steel, aluminum, or another alloy—impacts the precision of your parts, mold durability, and overall production costs.

Different applications demand different material selections:

- Steel: Ideal for high-volume production and parts that require exceptional durability and precision.

- Aluminum: Perfect for low-to-medium production runs, aluminum tools are easier to machine and cost less upfront. However, they may not withstand the wear and tear of long production cycles as effectively as steel.

- Custom Materials: For highly specialized parts, we may recommend custom tooling materials that offer unique benefits based on your specific requirements.

At Toolingsun, we consider your part specifications, including material types, tolerance levels, and production volume, before recommending the best tooling materials. This ensures that we meet your custom needs while optimizing cost and tool longevity.

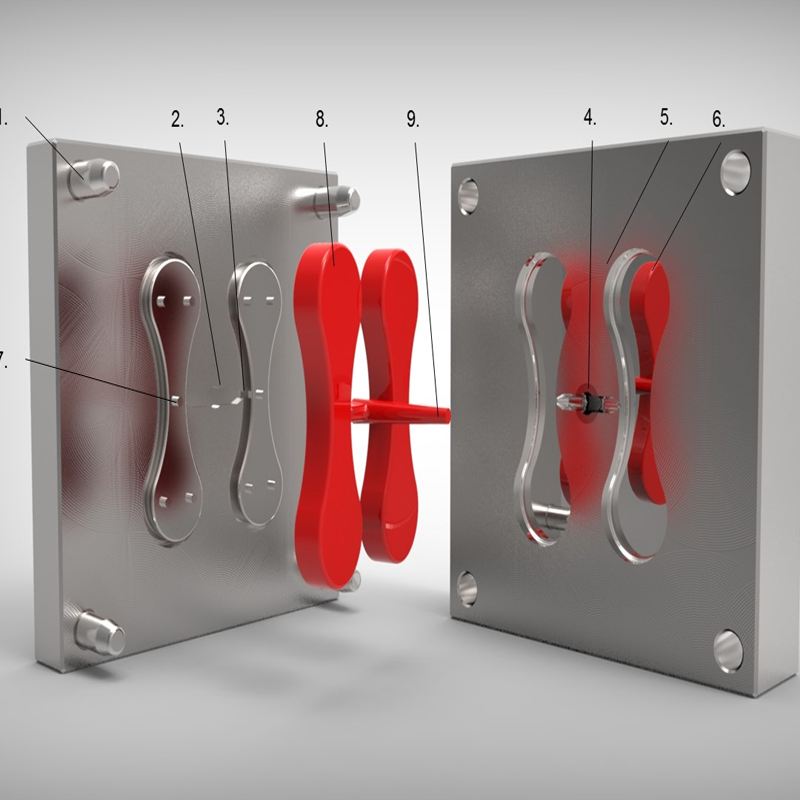

3. Understand the Molder’s Gate and Runner System Choices

The gate and runner system is a critical aspect of injection molding that directly impacts the part’s performance, cycle time, and overall quality. Different gate and runner designs help guide the plastic into the mold cavity and ensure that it fills properly.

When obtaining your tooling quote, it’s essential to ensure that the molder has a clear understanding of the optimal gate and runner system for your project. At Toolingsun, we provide comprehensive Design for Manufacturability (DFM) services to assess the most efficient system for your needs. We evaluate material flow, pressure distribution, and cooling times to ensure the best possible outcomes.

4. Be Transparent: Don’t Assume Anything

Transparency is key when communicating with your tooling supplier. While you may assume that your design details or specifications are clear, it’s essential to convey every requirement, no matter how small. Details that might seem like “common knowledge” could lead to misunderstandings or inaccurate quotes.

For example, if your part requires special ejection methods, complex undercuts, or specific tolerance requirements, make sure these are included in the documentation. Our team at Toolingsun always goes the extra mile to ensure that we fully understand your needs and ensure everything is accounted for in the tooling quote.

Additionally, don’t forget to consider the post-production phase. We work closely with our clients to define repair protocols, maintenance schedules, and tool longevity to minimize any surprises during production.

5. Avoid Being Misled by the “Low-Cost” Option

It might be tempting to choose the cheapest tooling option, especially if it comes from overseas suppliers. However, when you factor in the additional costs—such as shipping, repairs, ongoing maintenance, and potential delays—the “low-cost” tooling option often becomes more expensive in the long run.

Working with reliable, domestic suppliers like Toolingsun can help you avoid hidden costs. We offer competitive pricing for high-quality tooling that ensures longevity and efficiency. Our one-stop service provides you with everything from tool design and production to ongoing support and maintenance, giving you peace of mind throughout the process.

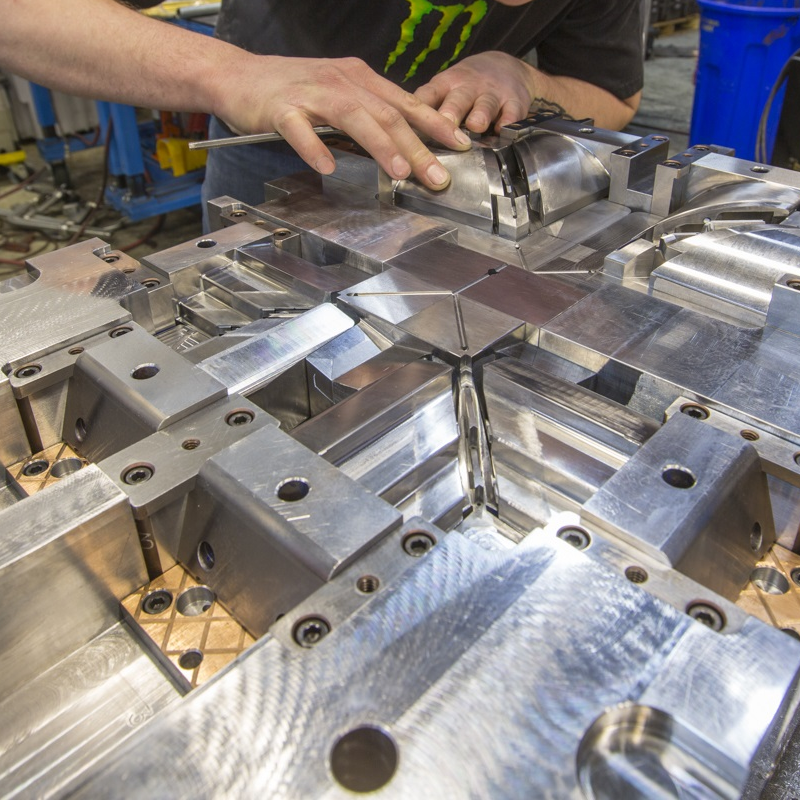

At Toolingsun, we take pride in offering custom services tailored to your unique project. Our experience with a wide range of industries allows us to handle everything from the simplest parts to highly complex and intricate designs. By using high-quality materials and advanced technologies, we can ensure that your tooling is built to last, providing long-term reliability for your production needs.

Conclusion: Why Toolingsun is Your Trusted Partner for Injection Molding Tooling

Securing an accurate and detailed tooling quote is a critical step in ensuring the success of your injection molding project. By clearly identifying cavitation needs, specifying materials, understanding gate and runner systems, being transparent in your communication, and considering the long-term costs, you can streamline the process and set your project up for success.

At Toolingsun, we are committed to providing you with high-quality tooling solutions that meet your exact specifications. Our custom service ensures that your tooling is tailored to your needs, and our one-stop service provides comprehensive support at every stage—from initial design to full-scale production.

Ready to get started? Contact Toolingsun today to discuss your tooling needs, and let us help you bring your products to life with precision and efficiency.