When producing plastic injection-molded parts, manufacturers often face a fundamental question: should you invest in complex tooling design or rely on machining technologies to complete the task? The answer depends on multiple factors, including cost, part complexity, tolerances, and production volume. At Toolingsun, we specialize in helping our clients navigate these challenges to achieve cost-effective and high-quality results.

Complex Tooling Design: Precision at a Price

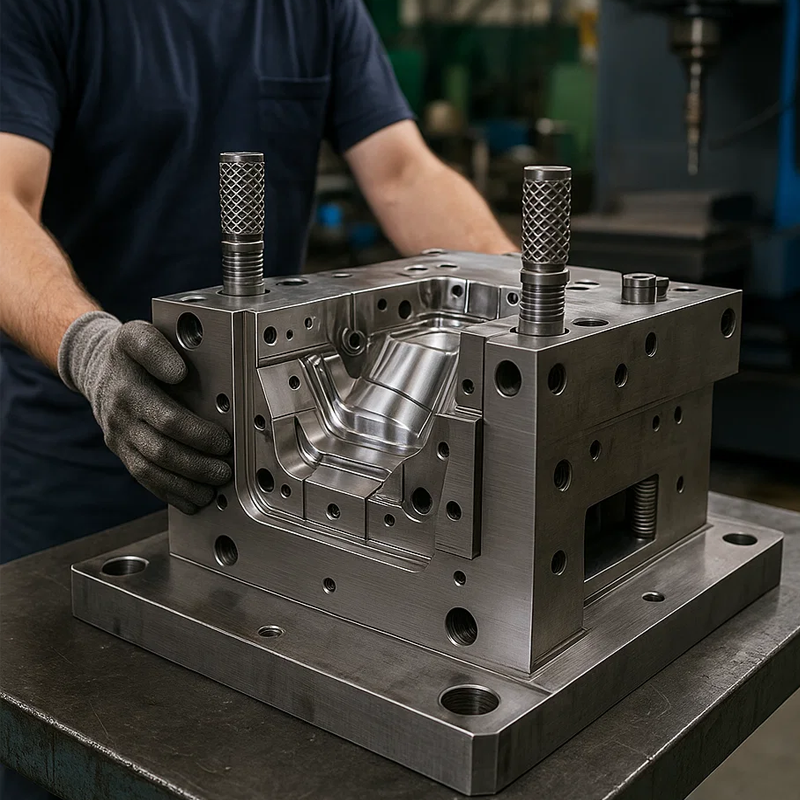

In the world of injection molding, precision is everything. A complex tool is designed to mold in all the intricate features and geometric details of a part. This approach is ideal when the part’s design demands high accuracy, and there’s a need for tight tolerances to meet exact specifications. However, this level of precision comes at a cost, both in terms of financial investment and time.

Designing a complex tool requires significant engineering expertise, including the development, testing, and validation phases. This process is more expensive because it involves specialized materials, in-depth analysis, and extensive prototyping. Additionally, complex tooling is typically suited for larger production volumes, as the high upfront costs of tool design are more easily justified when making a significant number of parts.

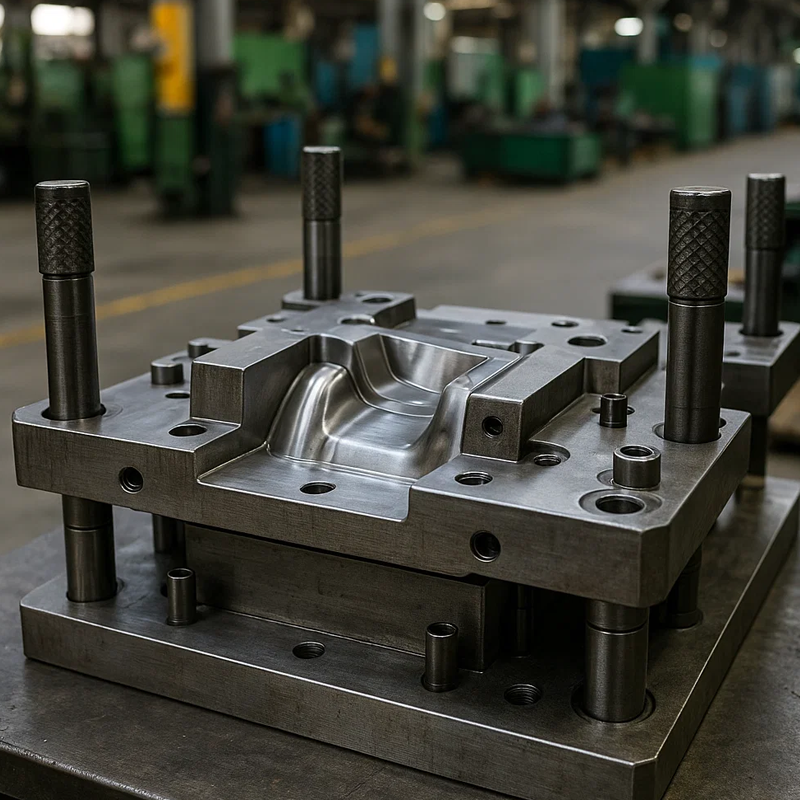

For example, in industries like defense manufacturing, where parts are often produced in low volumes, the cost of complex tooling may not be feasible. In these cases, it can be more economical to produce simpler tools and then use machining for specific features—such as slots, screw holes, or geometric adjustments—that the molded part requires. This method helps reduce the overall cost of production while still achieving the necessary functionality and precision.

When is Machining a Better Solution?

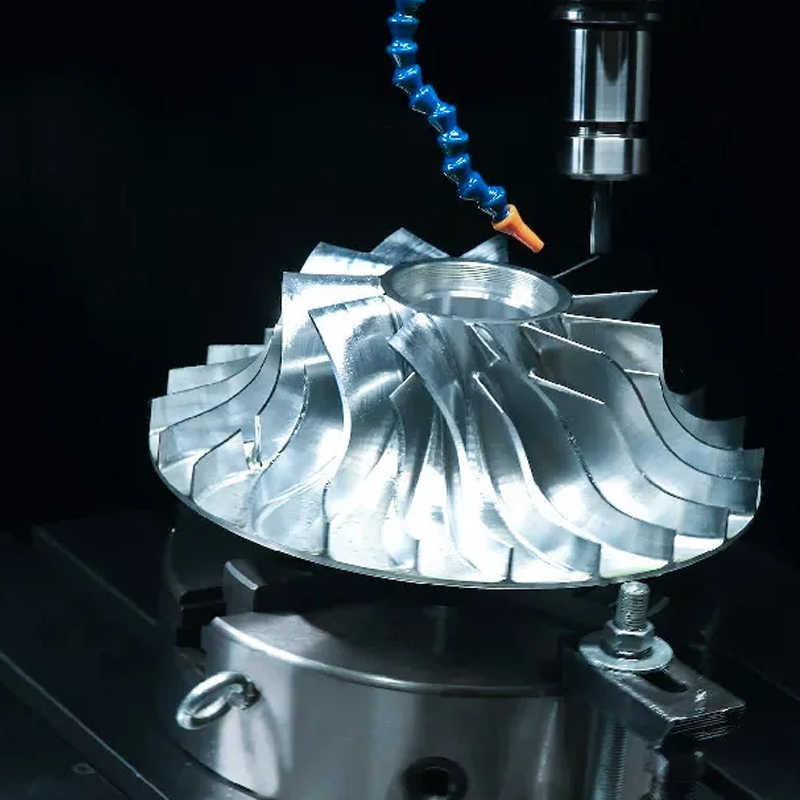

On the other hand, machining can sometimes offer a more cost-effective alternative to complex tooling. If the desired part features are relatively simple and can be added after the part is molded, machining can be a viable solution. The flexibility of machining technologies allows for precise modifications to molded parts, such as adding intricate features or adjustments that cannot be molded into the part initially.

Another benefit of machining is its ability to achieve tolerances that are difficult to maintain during the molding process. Certain materials, such as some polymers, may not consistently hold tight tolerances during the injection molding process. In these cases, machining can be used to meet the precision requirements after the part has been molded. This is particularly important for parts that require very tight tolerances, often down to ten-thousandths of an inch.

Cost and Time Considerations

When deciding between complex tooling design and machining, cost and time play a significant role in the decision-making process. Complex tooling involves a significant upfront investment, but it can be justified if the production volume is high enough to make the cost per part more reasonable. However, for low-volume production, complex tooling might not be the most efficient option.

In these cases, it’s often more practical to use simpler tooling combined with machining to produce the necessary features. This hybrid approach allows for faster turnaround times and more flexibility during the production process, without the large financial commitment required for complex tooling.

The Role of Expert Engineering in Decision-Making

At Toolingsun, we understand that determining the best course of action for your project can be challenging. That’s why we provide comprehensive engineering services to help our clients make informed decisions about tooling design and machining. Our experienced team conducts a thorough cost analysis to evaluate the best approach for your specific manufacturing needs.

We take into account various factors, such as your production volume, required tolerances, part complexity, and timeline, to provide tailored solutions that maximize your investment. With our in-house tooling capabilities, we ensure fast turnarounds without compromising on quality. Our goal is to deliver the most efficient and cost-effective manufacturing process for your parts, whether that involves complex tooling design, machining, or a combination of both.

The Stages of Tooling Design: A Closer Look

Understanding the stages of tooling design is crucial to making the right decision for your project. The process involves several key steps:

- Concept and Design:

The first step is to clearly define the part’s design requirements and determine the best tooling approach. This includes selecting the appropriate materials, understanding the part’s geometry, and determining how complex features will be integrated into the tool. At Toolingsun, we collaborate closely with our clients to understand their specific needs and provide expert guidance. - Prototyping and Testing:

Prototyping is an essential step in ensuring that the design meets the required specifications. During this phase, we create a test mold or use machining to produce a sample part. This allows us to identify potential issues and make any necessary adjustments before proceeding with full-scale production. - Tooling Manufacturing:

Once the design is finalized, the tooling is manufactured. Whether it’s a complex multi-cavity tool or a simpler design with post-machining, this phase involves precise manufacturing and assembly of the tooling components. We ensure that all tools are made to the highest standards, optimizing them for maximum efficiency and durability. - Final Testing and Adjustments:

After the tooling is complete, we perform extensive testing to ensure that the molded parts meet the required tolerances and quality standards. If any issues arise, adjustments are made to the tooling or machining processes to ensure the final product meets expectations.

Choosing the Right Tooling Solution for Your Project

At Toolingsun, we are committed to helping our clients make the best decision for their projects. Whether you need complex tooling for high-volume production or a combination of tooling and machining for low-volume or precision parts, our team has the expertise to guide you through the process. Our goal is to ensure that your parts are produced efficiently, cost-effectively, and to the highest quality standards.

If you’re unsure whether complex tooling or machining is the right choice for your project, contact us today. Our team of experts is here to help you navigate the decision-making process and provide a solution that aligns with your manufacturing needs.

Conclusion:

Choosing between complex tooling and machining depends on various factors, including production volume, part complexity, tolerances, and budget. At Toolingsun, we provide comprehensive solutions tailored to your unique needs, ensuring efficient production without compromising quality. Whether you’re looking for a custom tool design or machining services, we are here to support you every step of the way.Contact us now to learn more about how we can optimize your tooling design for injection molding and machining!