When you’re developing a new injection-molded component, prototyping is not a step you can afford to skip. It’s the safeguard that ensures your design is not only manufacturable but also capable of meeting stringent quality and performance standards. At Toolingsun, a professional factory in China specializing in plastic injection mold manufacturing, we often see customers debating between two common approaches: rapid tool prototyping and prototyping for production.

Both methods have their place, but the decision you make will directly impact cost, time, and long-term results. As a global partner providing one-stop service and OEM service to companies across industries, we’ve guided countless clients through this critical stage. In this article, we’ll provide a deep dive into both prototyping strategies, their advantages, limitations, and what you should consider before choosing the right path for your project.

What Is Rapid Tool Prototyping?

Rapid tool prototyping is designed for speed. By leveraging your CAD files, manufacturers can quickly build a temporary tool that produces a limited run of molded parts. This approach is appealing for teams that need to validate a concept quickly or demonstrate proof-of-concept to stakeholders.

Advantages of Rapid Tool Prototyping:

- Fast turnaround: Parts can be molded in days or weeks rather than months.

- Lower upfront cost: Because the tools are simplified, they require less investment initially.

- Early validation: You can hold a physical sample in your hand sooner to evaluate the design.

However, there’s a trade-off. Rapid tools are often fabricated from softer materials like aluminum, which cannot withstand the same pressures, cycle times, or repeated modifications as hardened steel production tools. This makes them less reliable for long-term production or high-volume runs.

Another concern is quality. While a rapid prototype can be “good enough” for basic evaluation, it may fall short when tested for dimensional accuracy, performance under stress, or consistency across multiple cycles. In many cases, customers who rely solely on rapid tooling end up facing expensive tooling changes or redesigns later in the production stage. What seems like savings upfront may actually drive costs higher in the long run.

What Is Prototyping for Production?

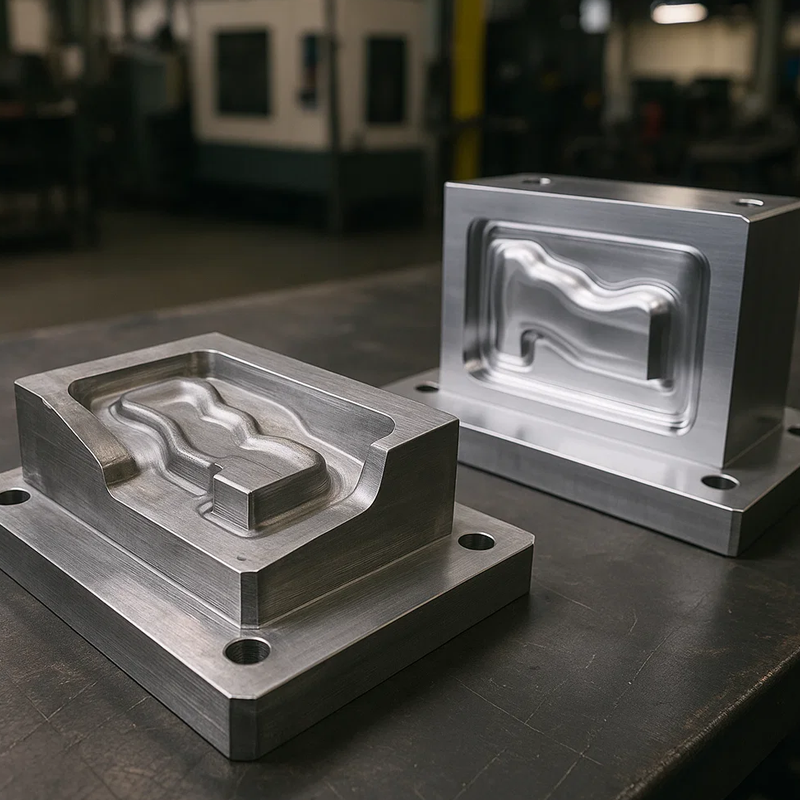

In contrast, prototyping for production is a more deliberate, structured process. Instead of rushing to produce a quick sample, manufacturers like Toolingsun design and build a pre-production tool — typically a single-cavity steel mold — that closely mirrors the final production environment.

Advantages of Production Prototyping:

- Design validation under real-world conditions: Parts are produced using the same materials, pressures, and cycles that will be used in mass production.

- Incremental testing and modification: Engineers can test for tolerances, shrinkage, warpage, and other critical variables, making design adjustments before full-scale production begins.

- Cost efficiency over time: While the upfront investment is higher, catching issues early prevents costly line stoppages or large-scale scrap during production.

- Smoother ramp-up: With issues addressed early, transitioning to multi-cavity tools and high-volume production is more seamless and predictable.

This method aligns closely with Design for Manufacturability (DfM) principles. By identifying and solving problems before scaling up, you save both time and resources, while ensuring that the final part delivers consistent quality.

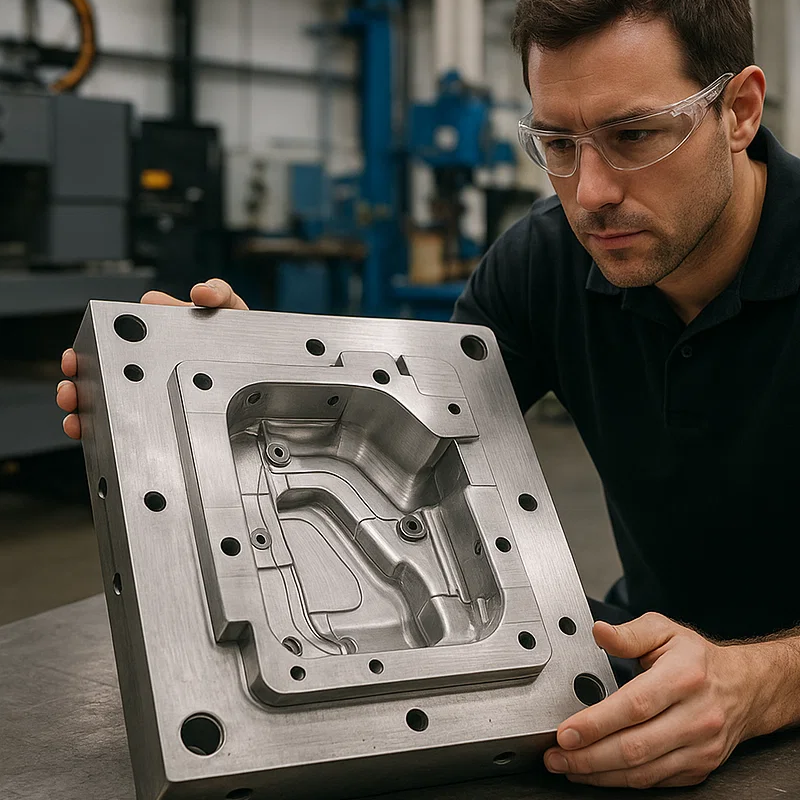

At Toolingsun, our engineering team collaborates directly with OEMs during this phase, acting as true partners rather than just suppliers. This collaborative approach gives customers confidence that the final product is optimized not only for performance but also for manufacturability.

Key Considerations When Choosing Between the Two

- Project Timeline

- If you’re under pressure to deliver samples within a week or two, rapid tool prototyping may be the better option.

- For projects with a longer development window and higher quality requirements, production prototyping is the smarter choice.

- Budget Constraints

- Rapid tooling requires less upfront investment, making it attractive for startups or early design exploration.

- Production prototyping, while more expensive initially, significantly reduces the risk of large-scale rework later.

- End-Use Application

- For functional prototypes that will be tested under real-world conditions — such as in automotive, medical, or industrial equipment — production prototyping is essential.

- For aesthetic models, investor presentations, or early-stage product demos, rapid tooling might be sufficient.

- Volume Requirements

- If you’re planning for mass production, investing in production prototyping is the logical step.

- If the part is for a limited run or niche application, rapid tooling may offer enough value.

The Role of an Experienced Manufacturing Partner

No matter which prototyping method you choose, the expertise of your manufacturing partner makes all the difference. As a leading factory in China with decades of experience, Toolingsun provides one-stop service that covers the entire lifecycle: from concept development and CAD design to mold fabrication, sampling, and full-scale production.

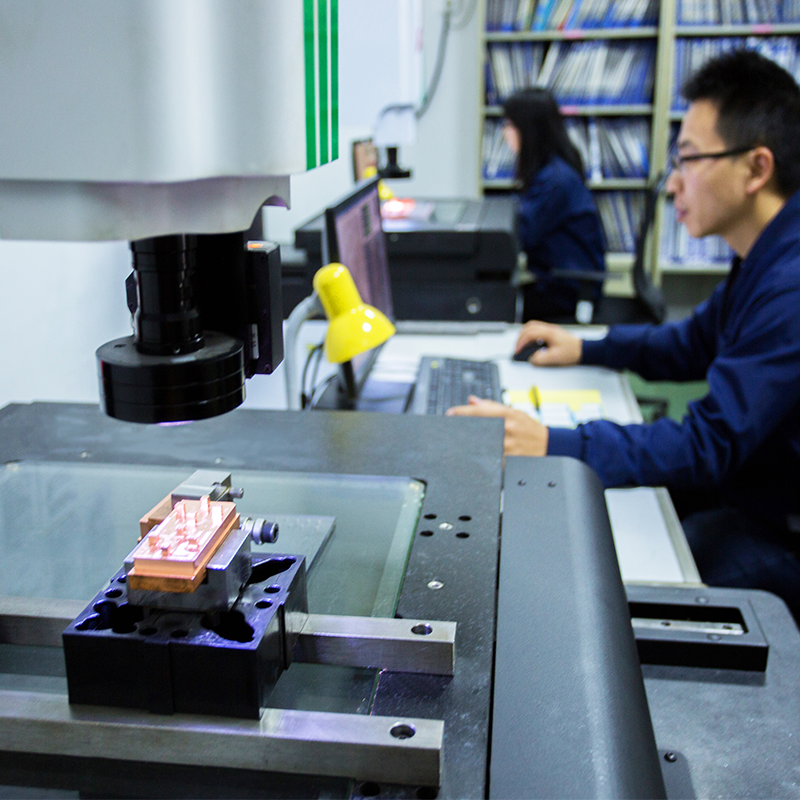

Our OEM service ensures that every project is tailored to the specific needs of our customers, whether they are multinational corporations or emerging startups. By combining advanced equipment, a skilled engineering team, and stringent quality controls, we give our clients the confidence that their products will perform as expected in the market.

We also emphasize transparency and long-term collaboration. Unlike many suppliers who focus only on delivering a part, we prioritize building partnerships based on trust, innovation, and shared success. This is why clients across industries — automotive, consumer electronics, healthcare, and industrial equipment — continue to rely on Toolingsun as their injection molding partner.

Looking Ahead: Choosing the Best Path for Your Project

Ultimately, the decision between rapid tool prototyping and production prototyping comes down to your project’s goals, resources, and long-term strategy. For short timelines, low cost, and basic validation, rapid tooling provides value. For high-stakes applications where quality, consistency, and performance are critical, production prototyping is the superior choice.

At Toolingsun, we help our customers make these decisions with confidence. As a trusted factory in China, we combine one-stop service and OEM service to provide tailored solutions for each client’s unique needs. Whether you need quick turnaround samples or a fully tested pre-production tool, our team has the expertise and capabilities to support you every step of the way.

Are you ready to take the next step in your injection molding journey? Reach out to our experts at Toolingsun today. Let us show you how our professional manufacturing services and long-standing experience as reliable suppliers can transform your concept into a high-quality, production-ready component.