Are you evaluating advanced molding technologies for a new product line? At Toolingsun, we speak with OEMs, product designers, and procurement teams every week about how to reduce part weight, improve surface quality, and lower unit cost without sacrificing strength. Water injection molding (WIM), also called water-assisted injection molding (WAIM), is one of the most practical process upgrades for medium-to-high volume production that delivers on all three goals. In this article we break down how WIM works, the eight core benefits, key design and material considerations, tooling implications, and when your program should choose WIM over other options.

What is Water Injection Molding?

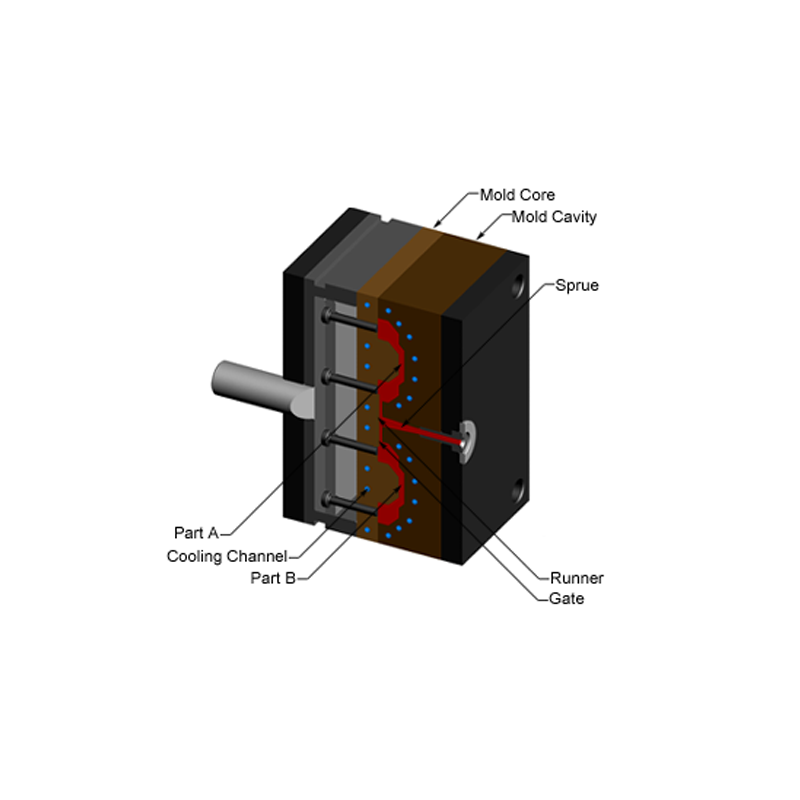

Water injection molding injects pressurized water into the molten plastic core during the molding cycle to form controlled hollow channels or partial cavities inside a part. The water displaces melt to the cavity walls, then is drained and recovered. Because water conducts heat much more effectively than air or inert gas, WIM changes both how the cavity fills and how the part cools — enabling thinner walls, faster solidification, and smoother internal surfaces compared with standard or gas-assisted molding.

At Toolingsun we integrate WIM into our one-stop service — from design for manufacturability (DFM) and mold design to full production runs — working with suppliers of pumps, seals, and corrosion-resistant steels so you get a reliable, manufacturable solution.

The Eight Key Benefits of Water Injection Molding

1. Controlled Hollow Structures — High Strength, Low Weight

WIM creates predictable hollow cores that keep exterior wall thickness while eliminating unnecessary mass inside. That improves the part’s strength-to-weight ratio — ideal for handles, housings, and structural consumer or automotive components where mass matters.

2. Shorter Cycle Times Through Faster Cooling

Water’s thermal conductivity is orders of magnitude higher than gas. The injected water removes heat from the core rapidly and uniformly, reducing cooling time — the longest segment of the molding cycle — and increasing throughput on the same press.

3. Improved Wall Uniformity and Dimensional Stability

Because water forces melt to flow evenly to cavity walls, you get more consistent wall thickness and less shrinkage variability. That translates to fewer warps, tighter tolerances, and less rework downstream.

4. Smooth Internal Surfaces Without Turbulence

Gas can create turbulence and leave rough or porous internal surfaces. Water flows stably and produces clean, low-friction interior channels — a major advantage for liquid-handling components, ducts, and any part where internal finish affects function.

5. Lower Material Usage and Reduced Cost per Part

By designing hollow cores where solid plastic isn’t needed, you materially reduce resin consumption. Over large production runs this yields substantial savings and a lower environmental footprint — attractive to procurement teams and sustainability goals alike.

6. Better Dimensional Accuracy and Fit-Up

Faster uniform cooling reduces residual stresses that cause distortion. The result: parts that assemble reliably with minimal secondary machining or adjustment — a crucial benefit for high-precision assemblies.

7. Design Flexibility for Complex Geometries

WIM enables long flow paths, complex hollow sections, and thin walls that would otherwise be impossible or impractical. This design freedom lets engineers optimize performance without massively increasing tooling complexity.

8. Competitive Long-Term Cost Savings

Although WIM requires specialized tooling and water-handling systems up front, the combined benefits — faster cycles, less resin, and lower scrap rates — produce a compelling ROI for medium and large volume programs.

WIM vs. Gas-Assisted Molding — How They Compare

Both processes form hollow cores, but they differ in tradeoffs. Gas-assist uses nitrogen or other gas; it’s simpler for some geometries and avoids water management. WIM outperforms gas in cooling speed, internal surface quality, dimensional control, and ability to produce thin, uniform walls. However, water requires corrosion control in tooling and careful drainage design. At Toolingsun we help customers pick the right approach based on part function, cycle expectations, and total cost of ownership.

Material and Design Considerations

Not every resin behaves the same under WIM. Typical compatible materials include PP, ABS, some PA grades and engineering thermoplastics that resist moisture uptake and tolerate the process window. Key design notes:

- Wall thickness: WIM enables thinner walls, but maintain uniformity to avoid weak sections.

- Channel layout: Design water channels to be drainable and to avoid trapping—integrate vents and drainage paths.

- Gate locations: Place gates to support even melt flow before water injection.

- Seals and drains: Provide integrated drain ports and seals for repeatable water recovery.

- Surface finish: Outside surfaces can be textured without compromising injection water performance, but textures should be validated in DFM.

Our in-house engineering team provides DFM reviews that quantify material choices and recommend parametric settings for pressure and water volume during the cycle.

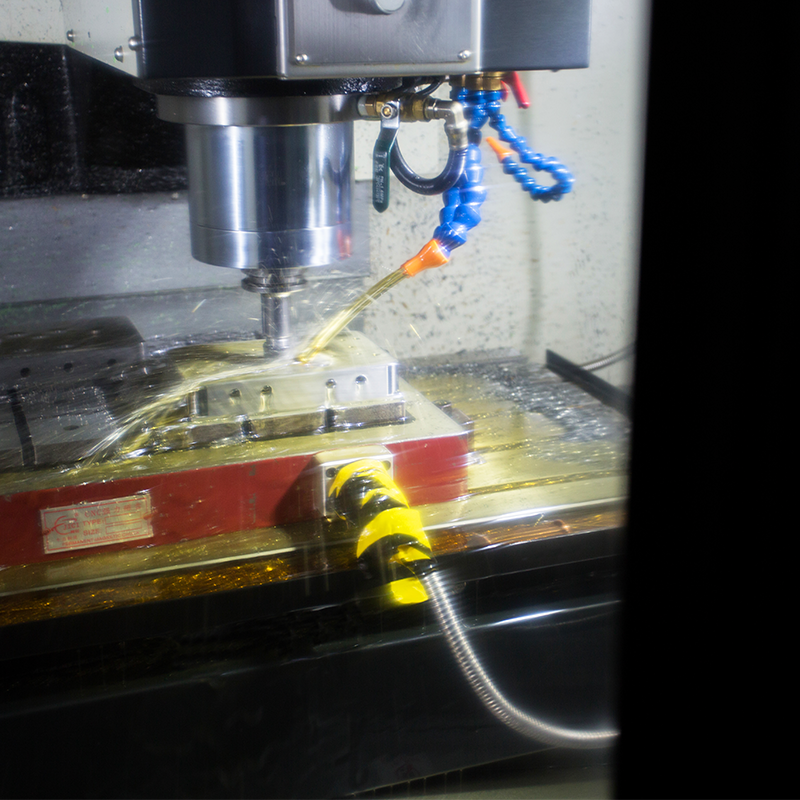

Tooling, Mold Life, and Corrosion Prevention

WIM tooling must be engineered for repeated water exposure. Best practices include:

- Material selection: corrosion-resistant steels or surface coatings (nitriding, hard chrome, special platings) on internal passages.

- Water management: use filtration and closed-loop water treatment to limit mineral deposits.

- Sealing systems: high-quality dynamic seals to prevent leaks and maintain pump pressures.

- Serviceability: design molds with accessible channels for cleaning and inspection.

Toolingsun offers OEM service for mold fabrication with corrosion-mitigating finishes and long-term maintenance plans. We work with trusted suppliers for pumps and filtration to ensure the factory runs reliably.

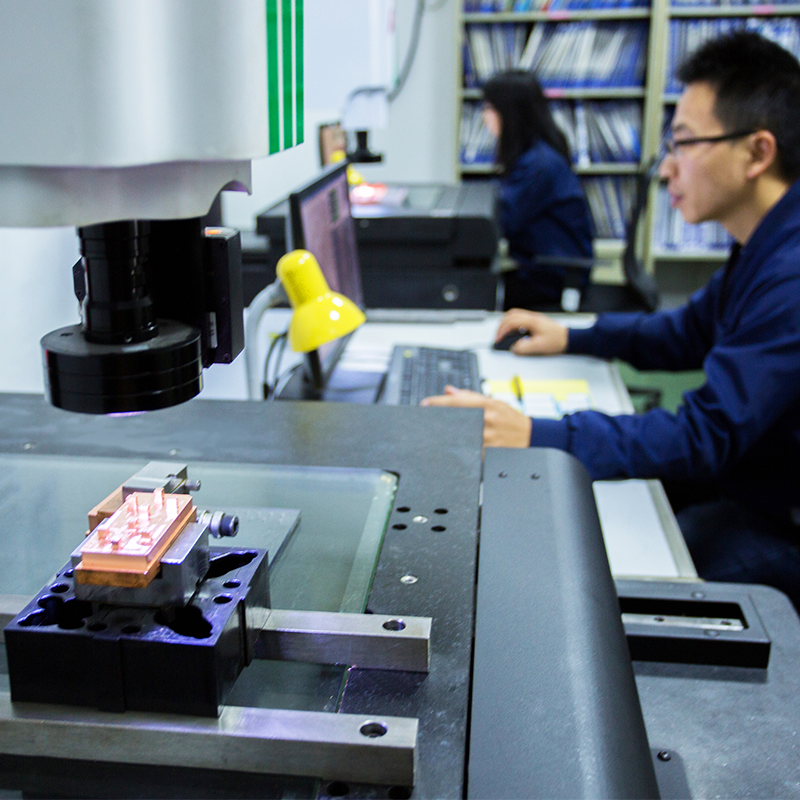

Quality Control and Production Considerations

WIM requires robust process control: water pressure, timing, melt temperature, and drainage are all critical to part consistency. Automated monitoring and SPC (statistical process control) are standard in our factory’s production lines. We perform trial runs, dimensional audits, and burst/pressure testing where needed to validate hollow structures meet specs.

Cost and ROI Analysis

Upfront costs: specialized pumps, modified mold inserts, and potential coating costs. Ongoing gains: reduced cycle times, lower per-part resin cost, reduced scrap and lower secondary finishing. For most medium to high volumes (tens of thousands+ parts), WIM often achieves payback within a reasonable run length. Toolingsun’s one-stop service includes a cost/ROI analysis during the quotation phase so you can make an informed decision.

When Should You Choose Water Injection Molding?

Consider WIM when your part:

- Requires internal hollow features or long flow lengths

- Benefits from improved internal surface finish

- Must meet tight dimensional tolerances at volume

- Has weight reduction or material cost targets

- Will be produced in medium to large annual quantities

If you’re unsure, we recommend a feasibility study — Toolingsun provides prototyping, pilot runs, and performance testing as part of our custom service to validate the approach before full production.

Conclusion

Water injection molding is a practical, proven route to lighter, stronger, higher-quality plastic parts — particularly when precision, surface quality, and cost efficiency matter. At Toolingsun our factory combines full mold design and build, process engineering, and production scale-up as a single one-stop service. We partner with reliable suppliers and provide OEM service for molds, pumps, and filtration systems so you get consistent, repeatable performance.

If you’re evaluating WIM for a new or existing product, we’d be happy to review your design and provide a free DFM analysis and ROI estimate. Contact Toolingsun today — let’s explore whether water injection molding is the right solution to meet your performance and cost targets.