In the ever-evolving world of consumer goods manufacturing, the demand for complex, visually striking, and functional products is on the rise. Among the various innovative molding techniques available, multi-color injection molding stands out as a game-changer. Whether it’s for creating products with soft-hard combination parts or intricate pattern formations, this molding technique ensures both aesthetic appeal and high performance. At Toolingsun, we specialize in providing cutting-edge tooling and mold solutions for multi-color injection molding, helping businesses bring their product visions to life while maintaining top-notch quality.

What Is Multi-Color Injection Molding and Why Is It Important?

Multi-color injection molding, also known as two-shot molding, involves injecting two or more different materials or colors into a mold during the same molding cycle. The benefit of this technique is that it enables manufacturers to produce parts with soft and hard material combinations or intricate patterns all in a single process, thus enhancing both functionality and aesthetics.

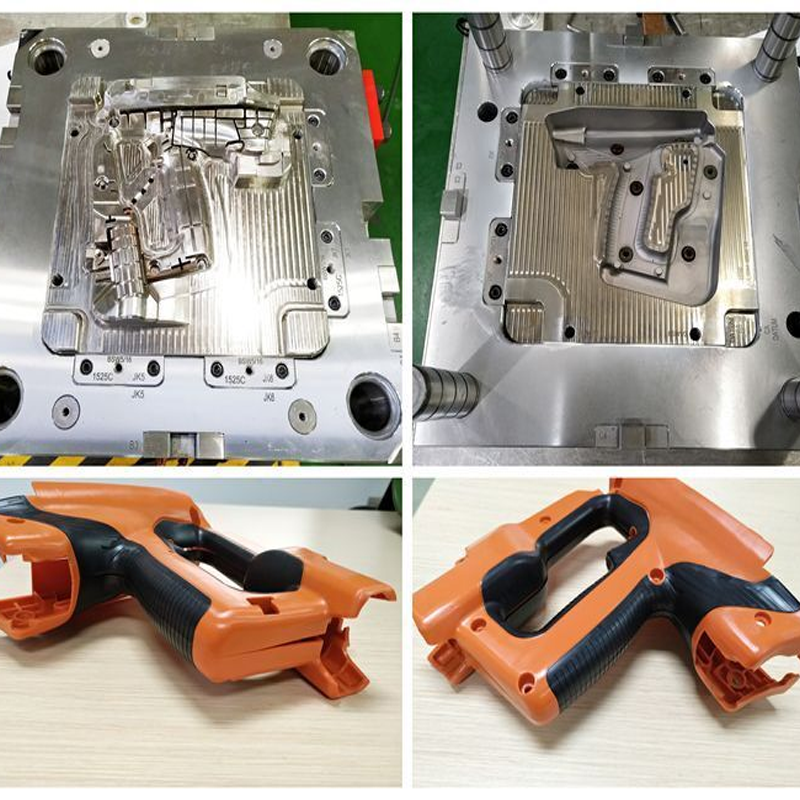

For instance, this process is commonly used in products like consumer electronics, automotive parts, medical devices, and consumer goods where different material properties—such as durability, flexibility, or grip—are required in the same product. With multi-color molding, it is possible to produce keypads, handles, or enclosures with both hard exterior surfaces for protection and soft inner sections for comfort or tactile feedback.

However, to ensure a successful multi-color molding process, precision tooling is essential. At Toolingsun, we focus on creating molds that are designed to handle the complexity of multiple materials being injected simultaneously, while maintaining product consistency and minimizing defects.

Key Customer Concerns in Multi-Color Molding Tooling

When customers approach us for multi-color injection molding tooling, several common concerns often arise. These typically include:

- Mold Design Complexity and Durability

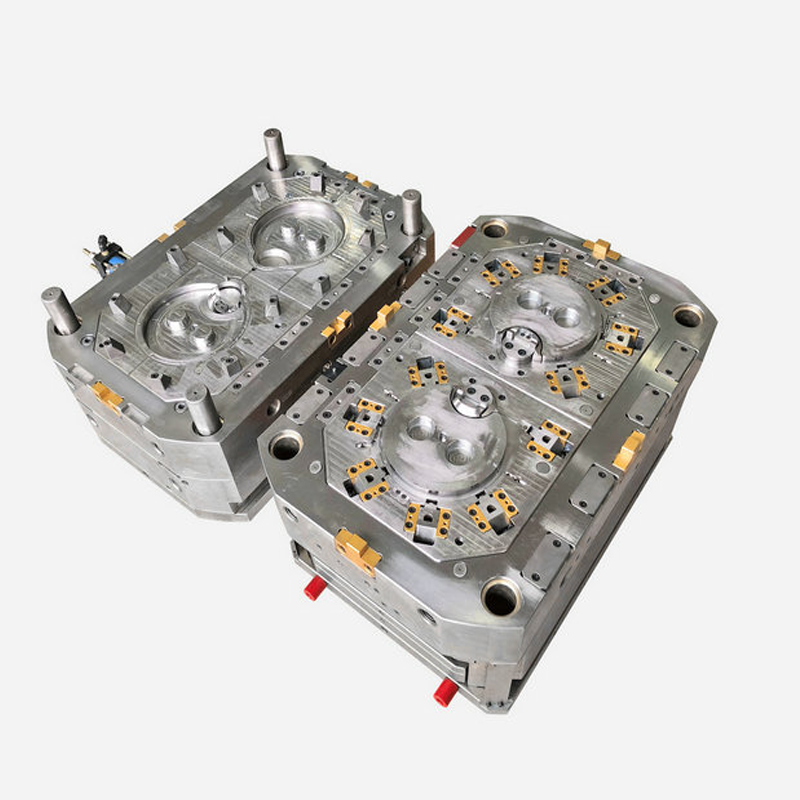

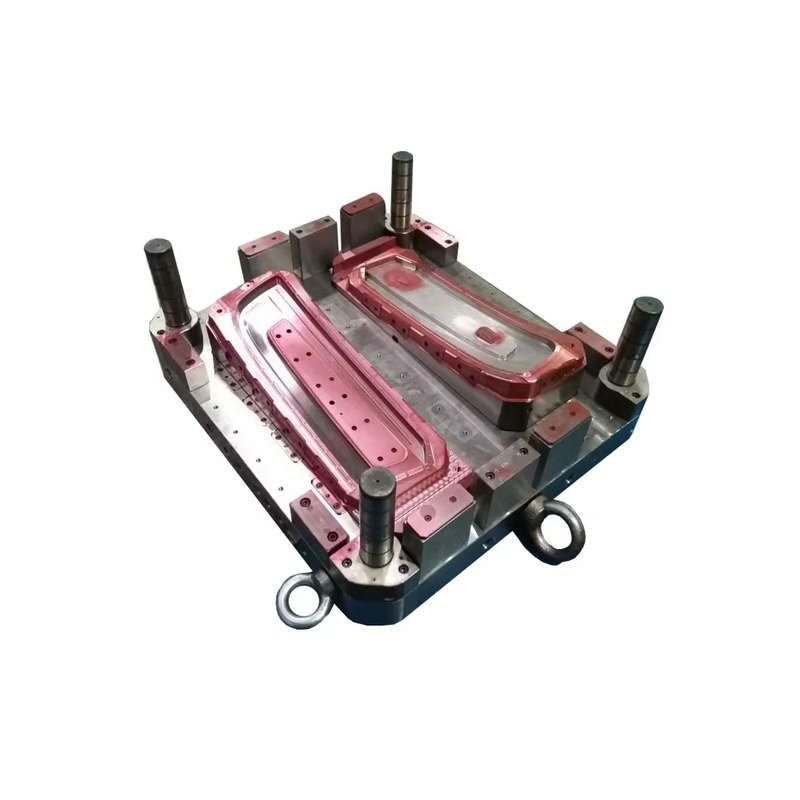

Multi-color molding requires molds that can handle the high pressures of both the soft and hard material injections without warping, causing defects, or impacting part quality. The molding tool needs to be designed for longevity, as frequent material changes can cause wear on the mold over time.Toolingsun’s Approach: We design custom molds that are capable of withstanding these pressures, incorporating durable materials like hardened steel and employing advanced coating techniques to enhance mold life. Our team uses state-of-the-art CAD/CAM software to design molds with exact specifications, ensuring that even the most intricate patterns or multi-material combinations are executed seamlessly.

- Precision and Tolerances

Precision in multi-color molding is crucial. If the soft and hard materials are not injected precisely in the right areas, it can result in product failure. Customers are often concerned about the tolerances and how accurately the final product matches the design.Toolingsun’s Approach: We use high-precision CNC machining and electro-discharge machining (EDM) to create molds with ultra-tight tolerances. Our focus on quality control ensures that the mold will deliver consistently accurate results. Each mold undergoes rigorous inspection to ensure that it meets the necessary design standards before production begins.

- Cycle Time and Efficiency

Another common concern is the cycle time. Multi-color molding, although efficient, can involve more complicated setups and processes. Customers want to know that their products will be produced on time, without compromising on quality.Toolingsun’s Approach: We optimize the tooling process to reduce cycle times without sacrificing quality. Using advanced cooling systems and the latest injection molding technologies, we ensure that the molding process remains efficient. Additionally, by employing parallel injection systems, we can ensure the simultaneous injection of multiple materials, speeding up production times.

- Material Compatibility

Not all materials are compatible with each other. When combining soft and hard materials or different colorants, compatibility becomes a concern, especially regarding adhesion between layers.Toolingsun’s Approach: We ensure material compatibility by working closely with our material suppliers to select materials that bond well during the injection process. Our experience in different material types—such as thermoplastic elastomers (TPE), polycarbonates (PC), and acrylonitrile butadiene styrene (ABS)—allows us to provide expert recommendations on the best materials to use for the specific application.

- Cost-Effectiveness and ROI

Finally, customers are always looking for the best return on investment (ROI) when considering multi-color molding. While the tooling setup can be more expensive than traditional single-material molds, the end result and cost savings in assembly and labor can make it worthwhile.Toolingsun’s Approach: By offering customized tooling solutions, we work closely with customers to design molds that maximize material usage, minimize waste, and reduce cycle times. We provide a clear cost breakdown, explaining the value of multi-color injection molding compared to traditional molding, and how it helps reduce labor and assembly costs in the long run.

The Role of Advanced Molding Technology in Achieving Perfect Results

At Toolingsun, we invest heavily in advanced technologies to ensure that every mold we create is optimized for multi-color injection molding. Our compression molding and injection molding machines are equipped with high-precision control systems that allow for rapid and accurate material injection.

We also understand the importance of mold maintenance in multi-color molding. With frequent use, the molds can wear down, leading to defects in the final product. Therefore, our molds are designed for easy maintenance and are built to last. Our technicians conduct regular mold inspections and perform any necessary repairs to keep the molds in optimal condition throughout the production cycle.

Additionally, our team uses in-line monitoring systems to detect any issues that may arise during the molding process. This enables us to adjust parameters in real-time, ensuring that we can resolve potential issues before they affect the product.

Why Choose Toolingsun for Your Multi-Color Molding Needs?

At Toolingsun, we are dedicated to delivering high-quality, customized molds for multi-color injection molding. Our expertise in designing and manufacturing molds that combine soft and hard materials, intricate patterns, and precise tolerances ensures that your products meet the highest industry standards.

By collaborating with our experienced engineers, you can achieve the optimal balance between functionality, aesthetics, and durability. Whether you’re developing keypads, consumer electronics, or automotive components, our team is equipped to provide tailored tooling solutions that align with your product goals.

If you’re ready to explore the benefits of multi-color injection molding for your next product, we invite you to get in touch with Toolingsun. Let us help you design the perfect mold and bring your vision to life with the precision, speed, and quality you deserve.

Contact Toolingsun today to discuss your project and discover how our multi-color injection molding solutions can elevate your product’s performance and design. Our team is ready to support you with expert advice, custom tooling, and unparalleled customer service.