Overview:

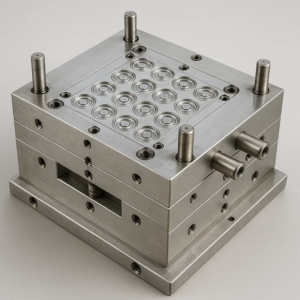

The Custom Aluminium Alloy Plastic Injection Medical Mold Tooling for Syringe Gasket Mold Series is designed to manufacture high-precision, durable gaskets for syringes used in the medical field. Constructed from premium aluminium alloy, this tooling ensures high strength, reliability, and operational efficiency. Utilizing advanced CNC machining, EDM (Electrical Discharge Machining), and tooling assembly, these molds provide superior precision and long-lasting durability in the production of syringe gaskets. As a trusted partner in the medical industry, we offer comprehensive one-stop services—from custom design and prototyping to full-scale production—ensuring the highest standards of quality, performance, and safety in compliance with ISO 13485 and other medical industry standards.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Aluminium Alloy |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available |

| Certification | ISO 9001, ISO 13485, IATF 16949 |

| Packaging | Custom |

| MOQ | According to your requirement |

| Lead Time | 25-30 days |

| Surface Treatment | Nickel Plating, Hard Anodizing, Polishing |

Benefits of Our Tooling:

- Precision Engineering: Achieved through CNC machining and EDM, ensuring high dimensional accuracy for critical medical parts like syringe gaskets, which must meet strict regulatory standards.

- Durability & Corrosion Resistance: Aluminium alloy provides an optimal balance between weight and strength, while surface treatments like nickel plating offer excellent protection against corrosion and wear, enhancing tool life in demanding medical applications.

- Advanced Tooling Process: The tooling assembly process ensures tight tolerances and smooth operation, facilitating the manufacturing of complex geometries required for syringe gaskets.

- Compliance with Medical Standards: We strictly adhere to ISO 13485 and IATF 16949 standards, guaranteeing that every mold meets the highest quality and safety requirements for medical devices.

Surface Treatment Options:

- Nickel Plating: Provides exceptional corrosion resistance and wear protection, ensuring the mold’s longevity and consistent performance even in challenging medical environments.

- Hard Anodizing: Enhances the surface hardness and wear resistance of the mold, making it ideal for high-precision and high-volume medical applications.

- Polishing: Refines the mold’s surface finish to reduce friction during the molding process, improving the quality and consistency of the final molded parts.

Quality Assurance:

Our quality assurance process ensures that each Custom Aluminium Alloy Plastic Injection Medical Mold Tooling meets the highest standards of precision and performance:

- Material Inspection: All materials, including the aluminium alloy, undergo strict inspection to ensure they meet medical-grade specifications.

- Dimensional Accuracy: Advanced testing tools like coordinate measuring machines (CMM) and surface roughness analyzers verify precise dimensions and material integrity, ensuring accurate mold performance.

- Process Validation: Through in-process audits and final product evaluations, we guarantee every tool is optimized for performance, compliance, and reliability.

- Post-Production Testing: Each mold undergoes rigorous testing, including leak-proof and pressure tests, to ensure functionality and durability during real-world use.

Why Choose Us?

- Expertise in Medical Molding: With over 20 years of experience in precision medical tooling, we understand the unique requirements for manufacturing medical components, ensuring reliable, high-performance products.

- Custom Solutions: From custom designs to tailored branding and packaging, we offer end-to-end OEM services that meet your exact specifications.

- Certified Manufacturing: Our manufacturing processes are fully compliant with ISO 13485, ensuring all molds meet stringent medical device regulations.

- Proven Quality Control: With a strong focus on quality, we utilize advanced testing and inspection protocols to guarantee that every mold delivers consistent, reliable results for your medical applications.

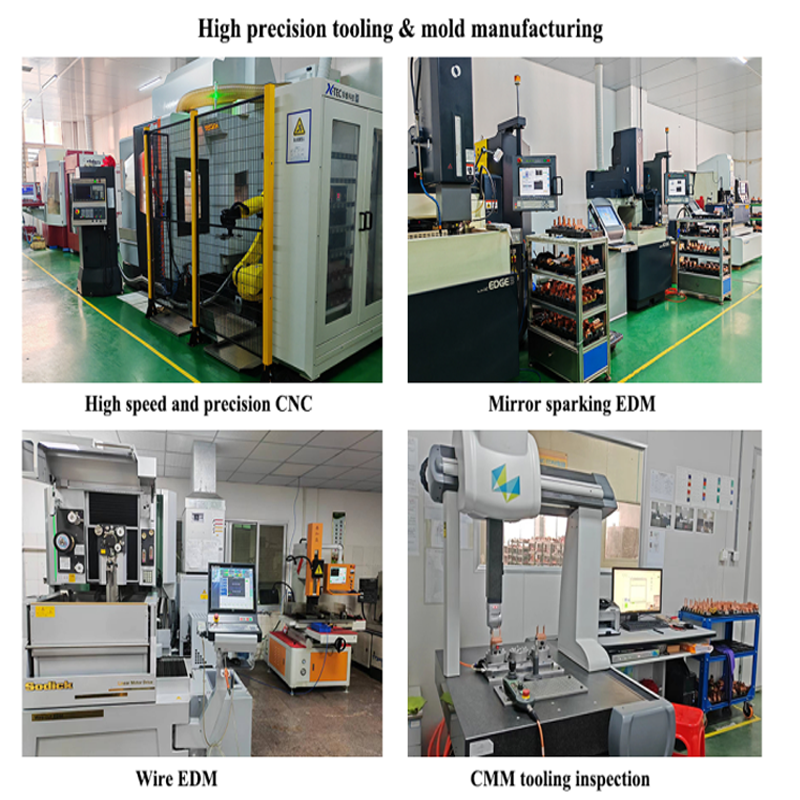

Factory Show:

Our state-of-the-art manufacturing facility is equipped with advanced technologies, including CNC machining, Mirror EDM, standard EDM, and precision tooling assembly processes. We leverage these cutting-edge tools to produce high-quality medical molds with superior precision and durability. Our quality control process includes the use of 3D projectors, sealing testers, and hardness testers to ensure every mold meets the required specifications.

Our facility is ISO 9001 and ISO 13485 certified, ensuring that all molds comply with the highest medical and industry standards. We also utilize automated vision systems and high-speed doming machines to further enhance the accuracy, productivity, and consistency of every production run.