Overview

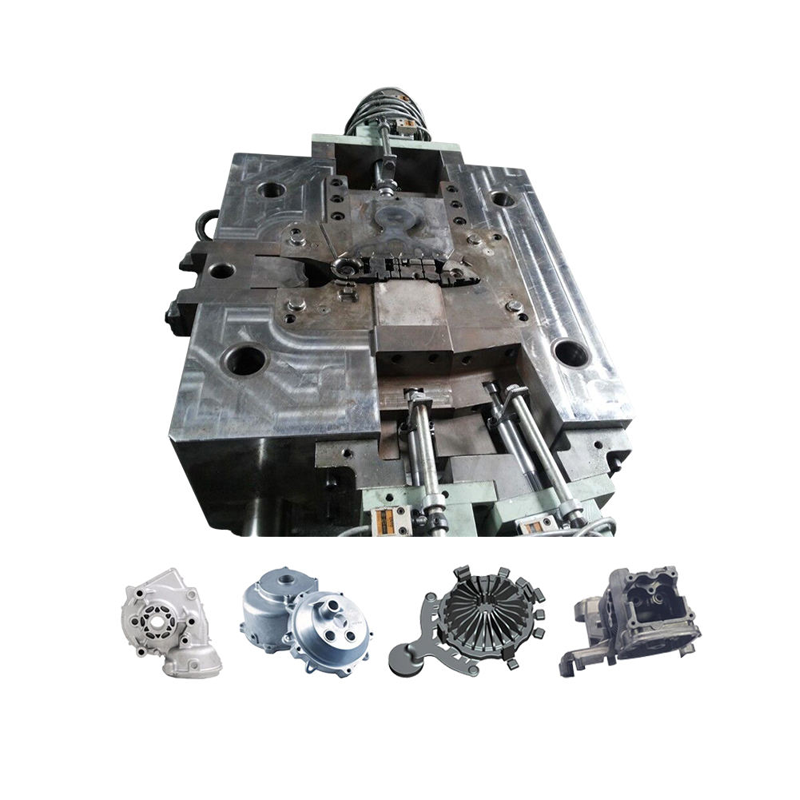

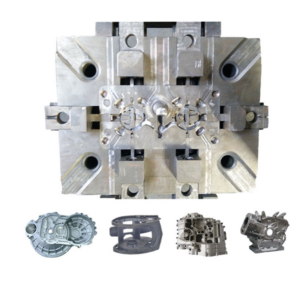

Our Custom Aluminum Die Casting Mold Tooling delivers robust, high-precision tooling solutions for engineering and industrial castings — from heat-sink housings and gearbox housings to pump bodies and structural brackets. Engineered for cold-chamber aluminum die casting, these dies are optimized for high thermal stability, controlled shrinkage, rapid cycle performance, and excellent dimensional repeatability. We combine advanced die design, precision CNC machining, EDM/WEDM, and modern surface treatments to produce tooling that supports high-volume production with consistent part quality and low maintenance.

Basic Information

| Specification | Details |

|---|---|

| Mold Type | Cold-chamber aluminum die casting dies: 2-plate, 3-plate, hot / cold runner adaptations, multi-cavity where applicable |

| Die Steel / Inserts | H13, S7, 718, or customized tool steels; PVD/Nitrided inserts for extended wear |

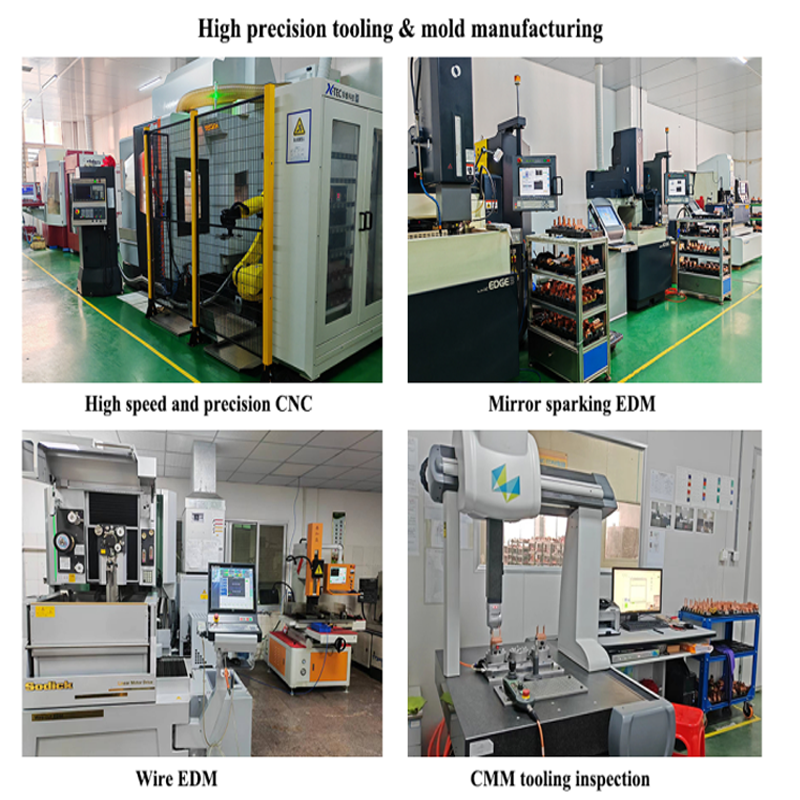

| Core Processes | 5-axis CNC machining, high-speed milling, mirror EDM, wire EDM (WEDM), precision grinding, tempering/heat treatment |

| Cooling & Thermal Control | Integrated cooled die systems, drilled/conformal cooling, thermal baffles, and insulated cores to manage solidification |

| Surface Finish (part) | Matte, fine-grain, or precision machined finish; cosmetic polishing available for visible faces |

| Tolerance | ±0.05–0.1 mm typical for medium features; ±0.01–0.03 mm achievable on critical machined surfaces |

| Shot Size / Part Weight | Designed to accommodate part weights from <10 g up to several kilograms (tooling customized per part) |

| Lead Time | Prototype dies: 3–5 weeks; production dies: 6–12 weeks (depends on complexity & cavities) |

| Expected Tool Life | 100k–1M+ shots depending on steel selection, coatings and process control |

| Venting & Gating | Optimized vacuum/venting systems, multi-gate layouts, and vacuum assist available for porosity reduction |

| Certifications | ISO 9001:2015; IATF 16949 support available for automotive projects |

| OEM Services | DFM, thermal & flow simulation, rapid prototyping (aluminum soft dies), trial casting, PPAP/FAI |

| Place of Origin | Xiamen, China |

Key Advantages

- Cold-Chamber Expertise for Aluminum — tooling engineered for high-temperature aluminum alloys with attention to shot-to-shot thermal control and die life.

- Precision Geometry & Thin-Wall Capability — tight tolerances and optimized cooling enable thin-wall, lightweight structural parts used in industrial and engineering applications.

- Reduced Porosity & Improved Mechanical Properties — advanced gating, vacuum assist and degassing recommendations delivered with each die to improve mechanical performance and reduce scrap.

- Fast Cycle & High Throughput — optimized runner systems and thermal layouts reduce cycle time while maintaining part quality for seasonal or continuous high-volume production.

- Durable Tooling — hardened inserts, nitriding, and PVD options extend die life for abrasive alloys or long-shot requirements.

- Design for Assembly — integrated features for machining allowance, thread bosses, ribs, and press-fit bosses to lower secondary operations.

Surface Treatment & Die Protection Options

- Nitriding / Surface Hardening — increases surface hardness, reduces galling and extends service life.

- PVD / DLC Coatings — minimize aluminum sticking and abrasion for special alloys or high-shot runs.

- Mirror & Cosmetic Polishing — for aesthetic or exposed surfaces requiring fine finish.

- Corrosion Protection & Passivation — for dies operating in humid environments or extended storage.

- Texturing — customized textures for aesthetic or functional surface grip.

Quality Assurance

All dies are manufactured under an ISO 9001 quality system with documented process controls and DFM checkpoints. We perform mold-flow and thermal simulations during design, followed by in-process inspections using CMM, laser scanning, and profilometry to verify core/cavity geometry and surface roughness. Trial casting runs include dimensional FAI, porosity analysis, mechanical testing samples (if required), and fatigue/pressure testing where applicable. Tool maintenance schedules, repair kits and shot-life monitoring protocols are supplied with production dies.

Our Factory

Our die shop integrates high-precision 5-axis CNC centers, high-speed milling, mirror and conventional EDM, and WEDM for complex core/cavity work. We employ heat-treatment furnaces and precision grinders to meet tight metallurgical and geometric standards. Dedicated die assembly and trial casting presses with vacuum assist and temperature control allow rapid validation and optimization. Onsite machining cells support die repairs and modifications, while our engineering team delivers CAD/CAM/CAE support, thermal modeling, and in-house prototype aluminum soft dies for quick validation. With robust project management and full documentation (DFM, PPAP/FAI), we supply turnkey die solutions from prototype to mass production.