Overview:

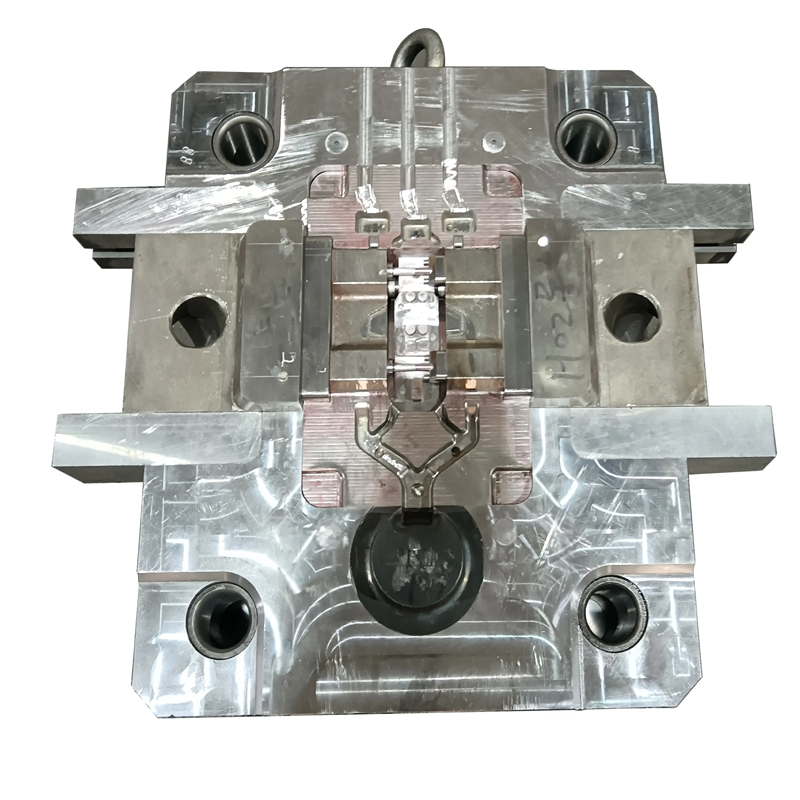

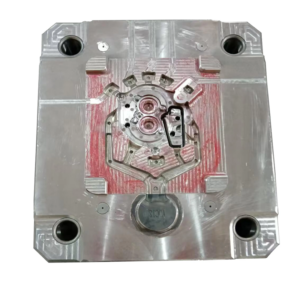

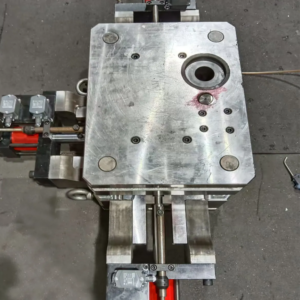

Our Custom Aluminum & Zinc Alloy Tooling Molds for Industrial Applications are engineered for high-precision, high-volume manufacturing of components across sectors such as electronics, consumer goods, and machinery. Constructed from aerospace-grade aluminum alloys (e.g., 7075, 6061) or premium zinc die-cast alloys (e.g., ZL102), these molds leverage advanced CNC machining and EDM techniques to deliver rapid thermal cycling, exceptional dimensional accuracy, and long service life. As full-service OEM tooling partners, we offer end-to-end solutions—from concept and CAD simulation through prototype validation, mold fabrication, and post-production support—ensuring molds that meet your exact specifications while optimizing cycle times and cost efficiency.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Mold Material | Aluminum Alloys (7075, 6061) or Zinc Alloy (ZL102) |

| Runner System | Hot Runner or Cold Runner, Insert Molding Support |

| Mold Design Software | UG/NX, SolidWorks, CATIA, Moldflow |

| Sample | Available upon request |

| Certification | ISO 9001, ISO 14001 |

| Packaging | Custom Anti-Rust, Shock-Proof Wooden Crates |

| MOQ | Based on Your Project Requirements |

| Lead Time | 20–30 Days (dependent on complexity & cavity count) |

Surface Treatment Options:

- Hard Anodizing (Type II/III):

Forms a dense, wear-resistant oxide layer on aluminum, improving hardness, corrosion resistance, and heat dissipation. - Electroless Nickel Plating:

Applies a uniform, pore-free nickel–phosphorus deposit to enhance surface hardness, chemical resistance, and corrosion protection on both aluminum and zinc molds. - Micro-Peening:

Induces compressive residual stresses on cavity surfaces to increase fatigue life and reduce micro-cracking under repetitive thermal cycles. - Precision Polishing (SPI A-1):

Achieves mirror-finish cavities to ensure flawless part ejection and surface quality of molded components.

Quality Assurance:

Our comprehensive QA protocol adheres to ISO 9001 and ISO 14001, encompassing:

- First-Article Inspection (FAI): Dimensional verification using CMM to ±0.005 mm tolerances.

- Hardness & Metallurgical Testing: Rockwell and Brinell hardness tests plus microstructure analysis to confirm alloy properties.

- Surface Roughness Measurement: Profilometers ensure Ra < 0.2 µm on critical cavity surfaces.

- Thermal Fatigue Trials: Simulated thermal cycling in specialized ovens to validate mold durability over extended runs.

- Trial Run Validation: On-press sampling and part inspection for dimensional accuracy, flash absence, and gating balance.

Factory Show:

Our ISO-certified facility houses state-of-the-art equipment, including 5-axis CNC machining centers for rapid cavity rough-machining, mirror and conventional EDM for fine detailing, and slow-speed wire-EDM for intricate undercuts. We employ automated temperature-controlled machining and adaptive tool-path strategies to minimize heat-induced distortion. Post-machining treatments occur on dedicated lines for anodizing, nickel plating, micro-peening, and precision polishing. A dedicated mold trial area with injection presses and thermal cycling rigs supports prototype validation. Our in-house QC lab, equipped with CMMs, optical comparators, profilometers, and hardness testers, ensures every mold meets stringent industrial standards before being crated in custom anti-rust packaging for shipment. Continuous process monitoring and lean methodologies guarantee on-time delivery, cost efficiency, and consistent mold performance across your production lifecycle.