Overview:

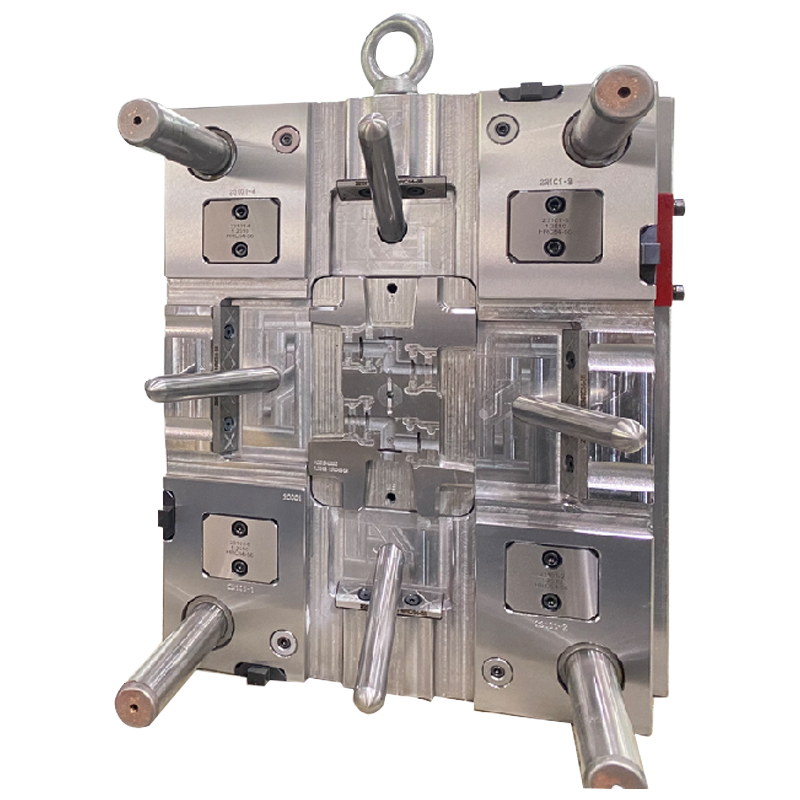

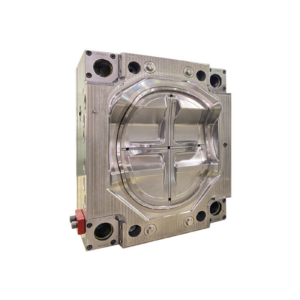

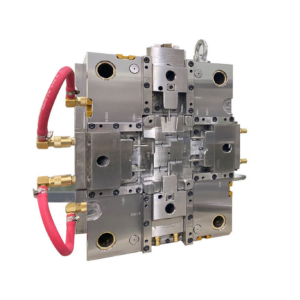

Our Custom High-Precision Plastic Injection Tooling Molds for Automotive Part Applications are engineered to deliver high-performance, durable components for the automotive industry. Manufactured from high-quality tool steels, including P20, H13, or advanced aluminum alloys, these molds are optimized for precise and reliable production of automotive parts. Utilizing state-of-the-art manufacturing techniques such as CNC machining, EDM texturing, and mold-flow analysis, we ensure flawless mold design and functionality. Our molds support a wide range of materials, including POM, PA66, glass-reinforced thermoplastics, and various engineering resins. With ISO 9001:2015 certification and adherence to strict industry standards, we provide comprehensive OEM services, from prototyping to mass production, offering fast turnaround times and superior mold longevity. Ideal for OEMs and Tier 1 suppliers, our molds guarantee high tolerance, dimensional accuracy, and consistent performance in demanding automotive applications.

Basic Information:

| Attribute | Details |

|---|---|

| Mold Type | Plastic Injection Mold |

| Mold Material Options | P20, 718, 738, NAK80, S136 |

| Mold Base Standards | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Runner System | Cold Runner / Hot Runner |

| Mold Gate Options | Slide Gate, Sub Gate, Pin-point Gate |

| Cavity | Single or Multi-Cavity |

| Design Software Supported | UG, PROE, CAD, SOLIDWORKS |

| Molding Equipment Used | CNC, Wire Cutting, Milling Machine, EDM |

| Compatible Raw Materials | POM, PA66, PBT, ABS, PC, PA6, PA66, PVC, PMMA, PS, etc. |

| Packaging Method | Wooden Pallet or Carton |

| OEM Services | Available — Please provide 2D/3D files or samples |

| Lead Time | Approximately 30 days |

| Certification | ISO 9001:2015, IATF 16949 |

Advantages of Our Molds:

- Superior Durability: Crafted from premium tool steels and alloys for extended mold life, ensuring a long-lasting solution for high-volume automotive production.

- Precision Engineering: Utilizes advanced CNC machining and EDM techniques to guarantee high dimensional accuracy and flawless surface finishes.

- Customization Flexibility: Fully tailored to customer specifications, from cavity configurations to material selection, ensuring optimal performance and functionality.

- Efficient Production: Designed for both high-volume production and rapid prototyping, enabling fast, cost-effective manufacturing of complex automotive components.

Surface Coating Options:

- Titanium Nitride (TiN) Coating: Applied via PVD deposition for enhanced wear resistance and reduced friction, ideal for high-temperature automotive environments.

- Diamond-Like Carbon (DLC) Coating: Offers ultra-low friction and exceptional corrosion resistance, extending the mold’s lifespan in harsh automotive conditions.

- Hard Chrome Plating: Known for superior wear resistance and high surface hardness, perfect for molds subjected to intense automotive conditions.

- PVD Multilayer Coatings (CrN, AlCrN): Combines materials to balance hardness, thermal stability, and release performance, especially for complex automotive mold designs.

Quality Assurance:

Our rigorous quality assurance process ensures the precision, reliability, and durability of every plastic injection mold. Our molds undergo stringent inspections using advanced equipment such as coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers. Additionally, we conduct thermal cycling and material testing to validate performance under automotive industry standards. Every mold is subjected to a final inspection, ensuring compliance with IATF 16949 and ISO 9001 certifications. We also implement automated vision systems to check for surface defects and ensure flawless mold integrity.

Factory Overview:

Our manufacturing facility is equipped with cutting-edge technologies, including high-precision CNC machining centers, Mirror EDM, conventional EDM, and slow-speed wire-cutting systems, ensuring exceptional mold accuracy and repeatability. With 15 rubber compression molding presses and two LSR injection molding units, we efficiently handle both high-volume production and custom tooling projects. Our facility is fully compliant with ISO 9001 and IATF 16949 certifications, ensuring we meet the highest industry standards. Automated systems, including AutoDryers and precision die-cutting, further enhance our operational efficiency and consistency across all stages of production.