Overview:

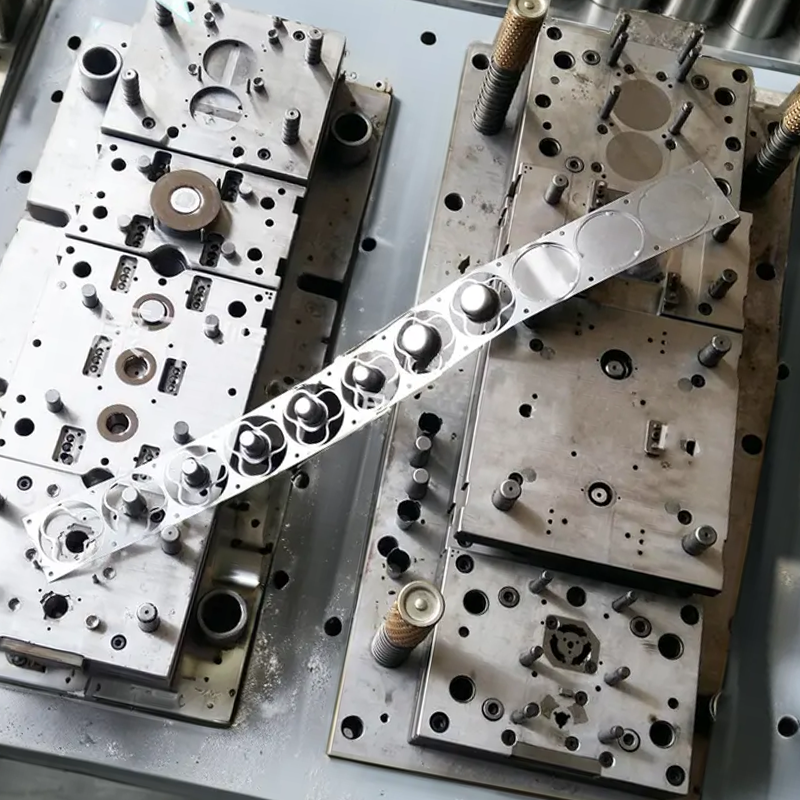

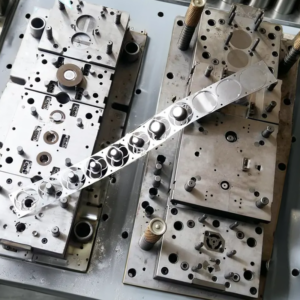

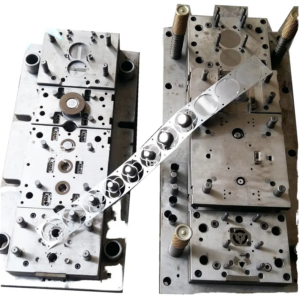

The Custom Steel Progressive Drawing Mold Punch Tooling for the Industrial Industry is a precision-engineered solution designed for high-efficiency, high-volume production of complex metal components. Utilizing advanced progressive stamping and deep drawing techniques, this tooling system performs multiple sequential operations—including piercing, bending, drawing, and forming—in a single press stroke, ensuring exceptional dimensional accuracy and production efficiency.

Crafted from premium-grade tool steels such as SKD11, DC53, or ASP23, and heat-treated for optimal hardness and wear resistance, these molds are tailored to withstand the rigors of continuous industrial manufacturing environments. As experienced OEM tooling specialists, we offer complete custom tooling services—from design and simulation to manufacturing, trial runs, and after-sales support—ensuring each progressive drawing tool meets your precise operational and production requirements. All tooling solutions are manufactured in compliance with ISO 9001 and IATF 16949 standards to guarantee durability, repeatability, and long-term value.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | SKD11, DC53, ASP23, H13, or per request |

| Runner System | N/A (progressive stamping system) |

| Mould Design Software | UG, AutoCAD, SOLIDWORKS, PROE, CATIA |

| Sample | Available upon request |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom-tailored anti-rust and protective packaging |

| MOQ | Based on customer specifications |

| Lead Time | 25–35 working days |

Surface Treatment Options:

- Titanium Nitride (TiN) Coating:

Adds a hard, wear-resistant, and low-friction golden coating to punches and dies, extending tooling life and reducing galling during high-speed operations. - Hard Chrome Plating:

Enhances surface hardness and corrosion resistance while improving release properties in deep drawing and forming operations. - Nitriding:

A thermochemical process that diffuses nitrogen into the steel surface, significantly increasing surface hardness, wear resistance, and fatigue strength without altering core toughness. - Precision Polishing:

Produces a mirror-finish on die cavities and punch surfaces, reducing friction, minimizing material adhesion, and improving the surface quality of stamped parts.

Quality Assurance:

Our tooling quality assurance process is built on strict ISO 9001 and IATF 16949 certified protocols. Each custom progressive drawing mold undergoes a comprehensive series of inspections, including:

- CAD/CAM simulation analysis for tool design validation.

- First-article and in-process dimensional verification using CMMs, height gauges, and micrometers.

- Hardness testing of critical tooling components post-heat treatment to confirm performance specifications.

- Surface roughness and flatness analysis for critical contact areas.

- Pilot run testing on press to validate tool performance under production conditions.

Detailed inspection records and material traceability reports accompany every tooling shipment, ensuring complete transparency and reliability.

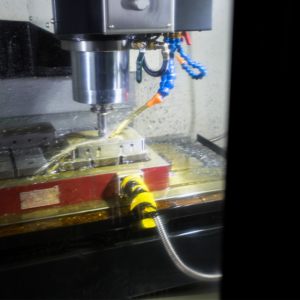

Factory Show:

Our fully integrated manufacturing facility is equipped with advanced tooling production and inspection equipment, including:

- High-speed CNC machining centers for precise die block and punch manufacturing.

- Mirror EDM and Wire EDM (Slow-Speed Wire Cutting) systems for ultra-fine cavity detailing and contour shaping.

- Surface grinding and milling machines for high-accuracy finishing.

- Heat treatment furnaces with vacuum and nitriding capabilities to optimize tooling hardness and durability.

- 3D coordinate measuring machines (CMM), profile projectors, hardness testers, and surface roughness analyzers for quality assurance.

Backed by ISO 9001 and IATF 16949 certifications, our factory ensures every tooling set meets stringent industrial standards for reliability, precision, and repeatability. Integrated automation systems, high-efficiency lubrication units, and precision die-setting equipment support efficient, scalable production for demanding industrial applications.