Overview:

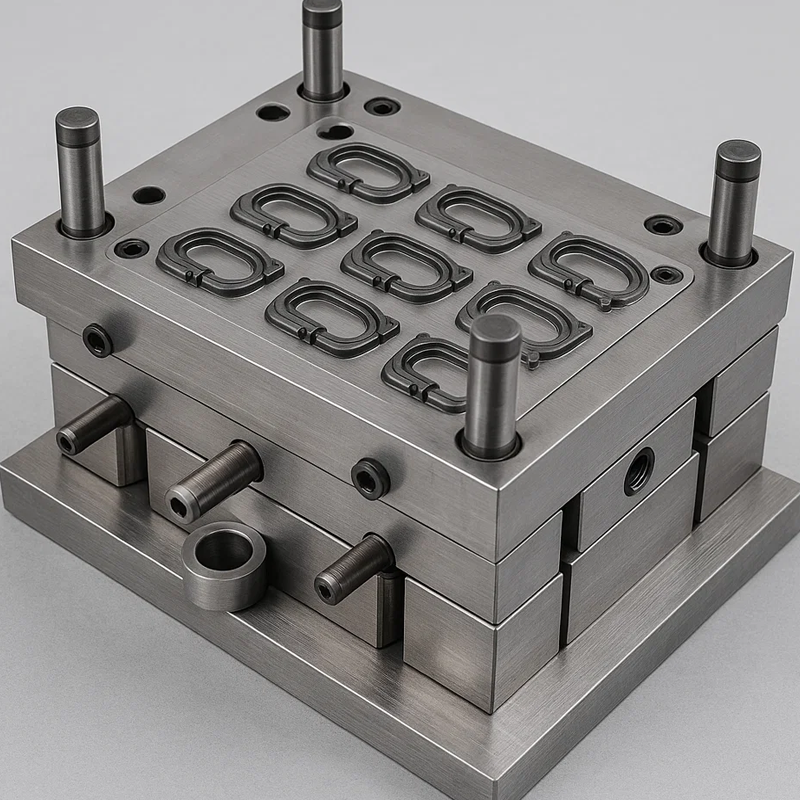

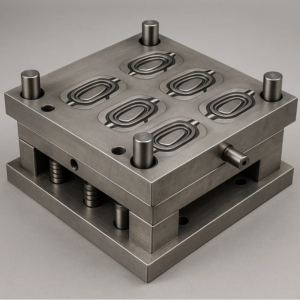

The Customized H13 Steel Automotive Seal Compression Mould Tooling Mold with Multiple Cavities is a high-performance, precisely engineered solution designed for producing durable and efficient automotive seal components. Manufactured using premium H13 steel, known for its excellent thermal conductivity and high wear resistance, this tooling mold is designed to meet the demanding requirements of the automotive industry. Through advanced compression molding techniques and precise cavity design, we ensure optimal part quality and high-volume production efficiency. The mold is produced using CNC machining for ultra-precise machining of complex geometries, ensuring tight tolerances and superior mold accuracy. Our custom molds are tailored to your exact specifications, offering cost-effective and reliable results. Certified to IATF 16949 and ISO 9001 standards, our molds provide exceptional durability, superior performance, and long-lasting reliability in automotive applications.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM / Private Label |

| Product Material | H13 Steel |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom |

| MOQ | According to your requirements |

| Lead Time | 25–30 days |

Surface Treatment Options:

- Nickel Plating

Provides exceptional corrosion resistance and enhances the mold’s durability, making it ideal for use in high-temperature, aggressive automotive environments. - Hard Anodizing

Increases surface hardness and wear resistance, ensuring the mold is capable of handling high-volume automotive molding with minimal wear. - Chromium Plating

Offers superior protection against wear, corrosion, and high-temperature degradation, ensuring long-term mold performance and consistency. - Polishing

Refines the surface finish to reduce friction, improve the quality of molded components, and increase the overall lifespan of the mold.

Quality Assurance:

Our Customized H13 Steel Automotive Seal Compression Mould Tooling Mold is produced under rigorous quality control protocols to ensure the highest standards of precision, durability, and performance. Our process is compliant with ISO 9001 and IATF 16949 certifications, ensuring that we meet the most demanding quality management standards.

Our inspection process includes:

- First-Article Evaluation: Ensures the initial mold meets all design specifications before mass production.

- In-Process Audits: Continuous monitoring of production to identify any deviations and maintain consistent quality.

- Final Product Assessment: Ensures all molds meet dimensional accuracy and material integrity standards.

We utilize coordinate measuring machines (CMM) for precise dimensional verification, hardness testers to check the mold material’s integrity, and surface roughness analyzers to verify the mold’s finish. Our automated vision systems further ensure consistent quality by inspecting the mold during the manufacturing process. Each mold undergoes thorough testing to verify its performance under extreme temperatures, pressure, and wear conditions, guaranteeing a long-lasting, reliable product.

Factory Overview:

Our manufacturing facility is equipped with cutting-edge technologies, including CNC machining, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC), allowing us to achieve unparalleled precision in mold fabrication. We operate 15 rubber compression molding presses and 2 LSR injection molding machines, ensuring we can scale production efficiently while maintaining the highest standards of quality.

To uphold exceptional quality, we employ advanced inspection tools such as 3D projectors, sealing testers, durometers, and elasticity gauges. These are overseen by our experienced and certified quality control team. Our processes are fully compliant with ISO 9001 and IATF 16949 certifications, ensuring reliable, high-performance manufacturing for automotive tooling.

Additionally, we integrate automated systems such as AutoDryers, high-speed doming machines, and precision die-cutting equipment to optimize production workflows, ensuring the consistent delivery of high-performance components that exceed the most demanding industry standards.