Overview:

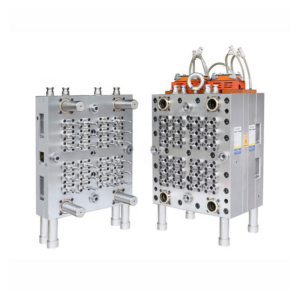

The Customized High-Durability Multi-Cavity Steel Tooling Molds for Medical Grade Collection Tubes are meticulously engineered to produce high-quality, durable medical components, specifically designed for the production of medical-grade collection tubes. Constructed from premium materials such as high-strength steel, these molds utilize advanced manufacturing technologies like CNC machining and EDM (Electrical Discharge Machining) to achieve exceptional precision and high performance. Our comprehensive services ensure tailored solutions that meet strict regulatory standards, including ISO 13485 for medical devices. These molds are designed for high-volume production, providing excellent repeatability and cost-efficiency in producing medical collection tubes with high-quality finishes and dimensional accuracy.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | High-strength Steel (e.g., P20, 718, S136, NAK80) |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available |

| Certification | ISO9001, ISO13485, IATF16949 |

| Packaging | Custom |

| MOQ | According to your requirement |

| Lead Time | 30-35 days |

Surface Treatment Options:

- Nickel Plating: Enhances the mold’s surface resistance to corrosion and wear, ensuring a longer lifespan, especially for high-precision medical applications.

- Hard Anodizing: Increases surface hardness and improves the durability of molds used in medical-grade production.

- Chromium Plating: Provides superior protection against wear, heat, and corrosion, extending the mold’s functionality over prolonged use.

- Polishing: Refines the mold surface for superior finish quality and minimal friction during the molding process, enhancing the quality of molded components.

Production Process:

- Design and Tooling: Detailed design and mold creation using precision CAD software, ensuring every mold meets the exact dimensions and specifications required for medical-grade collection tubes.

- Material Selection: Only high-quality, durable steel is selected to ensure long-term performance and reliable use in high-volume production.

- CNC Machining & EDM: Advanced CNC machining and EDM processes ensure high precision and repeatability for each cavity, achieving a perfect fit and ensuring the longevity of the mold in mass production.

- Surface Treatment: Molds undergo surface treatment options such as nickel plating or hard anodizing to optimize durability and maintain smooth performance throughout production cycles.

- Quality Control & Testing: Rigorous inspection and testing processes including dimensional checks, hardness testing, and final product assessment, all conducted in accordance with ISO 9001 and IATF 16949 standards to meet the highest medical device manufacturing requirements.

Quality Assurance:

Our Customized High-Durability Multi-Cavity Steel Tooling Molds for Medical Grade Collection Tubes undergo a comprehensive quality assurance process, ensuring the molds meet stringent medical industry standards. These processes include:

- ISO 9001 and IATF 16949 certifications ensuring a consistent, high-quality manufacturing process.

- First Article Inspection (FAI), in-process audits, and final product assessments to guarantee every mold meets exact specifications.

- Advanced Testing Equipment such as Coordinate Measuring Machines (CMM) for dimensional accuracy, Hardness Testers for material integrity, and Surface Roughness Analyzers for optimal surface finish quality.

- Automated Vision Systems and Electrical Conductivity Testers to verify functionality and performance across all molds.

Why Choose Us?

- Precision Engineering – Using CNC machining and EDM, we ensure the highest levels of precision and repeatability in mold fabrication.

- Durability and Efficiency – Our high-durability molds are designed to withstand high-volume production, providing cost-effective solutions without sacrificing quality.

- Customized Solutions – We offer fully customizable molds, tailored to your specific medical-grade requirements, from design to mass production.

- Certified Quality – Our molds are manufactured under the strictest quality control processes and comply with the highest industry certifications, including ISO 9001, IATF 16949, and ISO 13485.

- End-to-End Service – From prototyping to final mass production, our one-stop service model covers every aspect of your tooling needs.

Factory Show:

Our manufacturing facility is equipped with state-of-the-art technologies, including CNC machining centers, Mirror EDM, and Slow-Speed Wire Cutting (WC) to ensure high-precision mold fabrication. We operate 15 rubber compression molding presses and 2 high-speed LSR injection machines for efficient, high-volume production of medical-grade components. Our facility is certified ISO 9001 and IATF 16949, and we utilize cutting-edge inspection equipment like 3D projectors, sealing testers, and Shore durometers to ensure product integrity. With fully integrated automation systems, we optimize production efficiency, consistency, and quality, making us a trusted partner for high-performance medical tooling solutions.This comprehensive description outlines the advanced manufacturing process, precision, and high standards of quality control used in producing Customized High-Durability Multi-Cavity Steel Tooling Molds for Medical Grade Collection Tubes while emphasizing the benefits and certifications that assure reliability in the medical device industry.