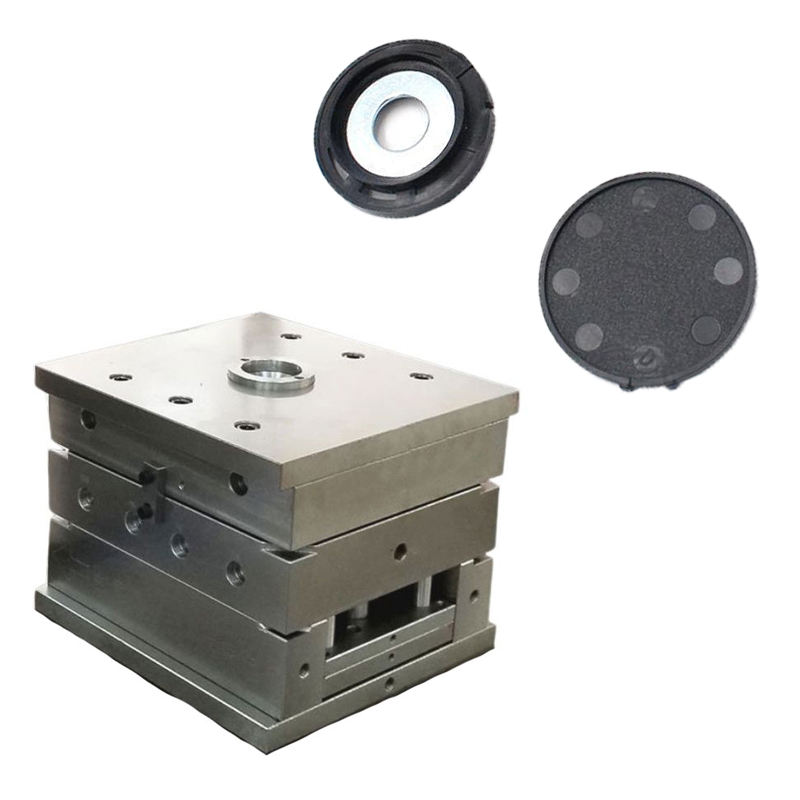

Overview:

Our High-Precision Injection Mold Tooling for Custom Plastic Shell Covers in Kitchen Appliances is meticulously engineered using top-grade materials such as P20 steel and S136 steel. These molds are manufactured through advanced techniques like CNC machining, Electrical Discharge Machining (EDM), and precision grinding, ensuring superior accuracy and long-lasting durability. Designed for versatility, our tooling solutions support both low-volume runs and large-scale production, delivering consistent, high-quality performance for a wide range of kitchen appliance applications. With our full-service OEM offerings, we provide end-to-end support, from custom design and prototyping to large-volume manufacturing.

Product Specifications:

| Attribute | Details |

|---|---|

| Mold Type | Injection Mold |

| Mold Material Options | P20, S136, 718, 2738, NAK80 |

| Mold Base Standards | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Runner System | Cold Runner / Hot Runner |

| Mold Gate Options | Pin-Point, Sub Gate, Valve Gate |

| Cavity | Single or Multi-Cavity |

| Design Software Supported | CAD, SOLIDWORKS, UG, PROE |

| Molding Equipment Used | CNC, Wire Cutting, EDM, Milling |

| Compatible Materials | ABS, PP, Polycarbonate, Nylon, PE |

| OEM Services | Available – 2D/3D files or samples required |

| Lead Time | 25–40 days |

| Certification | ISO 9001, IATF 16949, CE, RoHS |

Surface Treatment Options:

- Anodizing: Enhances the mold’s corrosion resistance and surface hardness, ideal for components exposed to regular use in kitchen appliances.

- Electroplating: Adds a shiny, corrosion-resistant finish for improved durability and an aesthetically appealing surface.

- Laser Etching: Provides precise, high-contrast markings and logos on the plastic shells, ensuring long-lasting, clear visuals.

- Textured Coating: Adds a grain or patterned texture for improved grip and visual appeal, providing a unique touch to the finished product.

Key Advantages of Our Tooling:

- Precision Engineering: Our molds are created using advanced CNC machining and EDM techniques, achieving tolerances of ±0.005mm for precise, high-quality plastic shell covers.

- Customizable Materials and Designs: We offer compatibility with a wide range of plastics and support for various design features, ensuring a tailor-made solution for each client’s needs.

- Durable, Long-Lasting Tooling: Using high-quality, hardened steel and innovative coatings, our molds are designed to withstand high volumes of production while maintaining performance and consistency.

- Optimized for Efficiency: Our advanced cooling systems and automated ejection processes reduce cycle times, enhancing production speed and maintaining consistent quality.

Quality Assurance:

Our quality assurance for Custom High-Precision Injection Mold Tooling adheres to strict industry standards, backed by ISO 9001 and IATF 16949 certifications. Each mold undergoes a multi-stage inspection process, including dimensional accuracy checks with Coordinate Measuring Machines (CMM), surface finish analysis using Keyence optical comparators, and material integrity tests with Rockwell hardness testers. We conduct mold flow simulations and process capability analysis to ensure that every tool meets the required specifications. Additionally, production-grade trials validate the thermal stability and ejection performance of the molds, ensuring they comply with global standards for quality and reliability.

Why Choose Us:

- Precision and Expertise: With extensive experience in manufacturing tooling for kitchen appliances, we offer precision molds that ensure an excellent fit and durability for plastic shell covers.

- Comprehensive OEM Services: From initial design to mass production, we offer full support, providing custom solutions that meet your exact specifications at every stage.

- Certified Quality Control: Our manufacturing process is ISO 9001 and IATF 16949 certified, ensuring that each product is rigorously tested for compliance with the highest standards.

- Efficiency and Scalability: Our advanced production methods, coupled with automated systems, ensure rapid and scalable production that does not compromise quality, meeting your demands efficiently.

Contact us today for customized plastic molding solutions that enhance your kitchen appliance designs and deliver long-lasting performance!

Factory Overview:

Our manufacturing facility is equipped with cutting-edge technology, including CNC machining centers, mirror and conventional EDM, and slow-speed wire cutting machines, ensuring precision in mold fabrication. The production floor houses 15 rubber compression presses and two high-speed LSR injection molding units, designed to accommodate both large-volume orders and intricate custom tooling projects. Our fully automated systems—including AutoDryers, high-speed doming stations, and precision die-cutting machines—enhance production efficiency while maintaining the highest standards of quality. Rigorous inspection protocols, supported by advanced tools like 3D optical projectors and sealing integrity testers, ensure that every component meets the industry’s toughest standards.