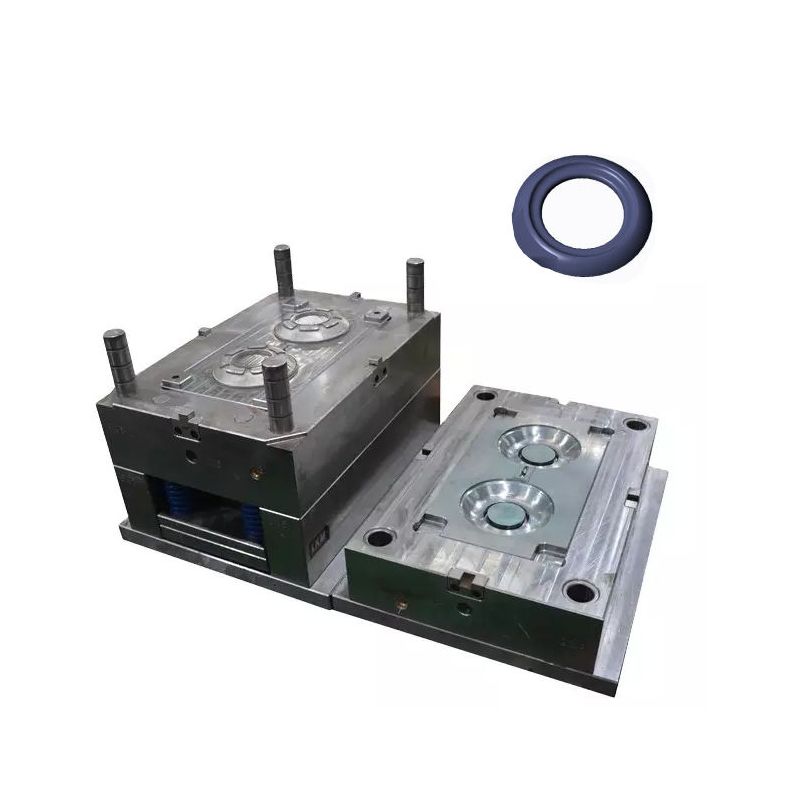

Description:

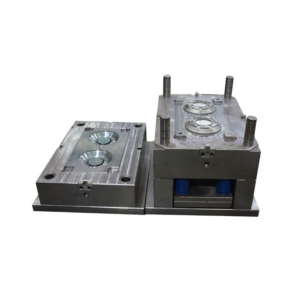

OEM Aluminum Alloy Plastic Injection Mould Tooling for Shower Nozzle Heads Holder is a precision-engineered mold solution designed for the high-performance production of shower nozzle heads holders. Manufactured using premium aluminum alloy material, these molds are ideal for producing durable, lightweight, and corrosion-resistant components. The advanced plastic injection molding process ensures superior accuracy and efficiency, producing consistent high-quality parts for the shower and bathroom industry. Our manufacturing process integrates state-of-the-art technologies such as EDM (Electrical Discharge Machining), CNC machining, and precision injection molding, guaranteeing reliable and precise results.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Aluminum Alloy |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD |

| Surface Treatment | Anodizing, Polishing, Nickel Plating |

| Sample | Available |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom |

| MOQ | According to Customer Requirement |

| Lead Time | 25-30 days |

| Size | Customized |

| Production Capacity | High Volume Production |

| Temperature Resistance | Up to 230°C |

Surface Treatment Options:

- Anodizing: Improves surface hardness and provides excellent corrosion resistance, making the mold suitable for high-performance applications.

- Polishing: Refines the surface finish, ensuring smooth contact during the molding process and reducing friction during component extraction.

- Nickel Plating: Enhances mold durability, improves corrosion resistance, and increases mold life, particularly in humid and corrosive environments.

Quality Assurance:

Our OEM Aluminum Alloy Plastic Injection Mould Tooling for Shower Nozzle Heads Holder is manufactured under the highest quality standards to ensure the optimal performance of the final product. We have ISO 9001 and IATF 16949 certifications, which guarantee our adherence to global quality management systems. We employ a series of rigorous quality assurance processes throughout production:

- Feasibility review to ensure manufacturability.

- First Article Inspections (FAI) and in-process audits.

- Use of coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers to verify dimensional accuracy.

- Automated vision systems and material testing to validate mold integrity and performance.

- Thermal cycling tests to simulate real-world temperature fluctuations and ensure the mold’s longevity.

Each mold is also subjected to leak-proof validation and material compatibility checks, ensuring the product consistently meets the required standards.

Why Choose Us?

- Advanced Manufacturing Technology: We utilize cutting-edge technologies such as EDM, CNC machining, and precision injection molding to produce high-precision molds that guarantee high performance.

- Customization Expertise: Our factory offers full OEM services, including custom design, size, and material selection, tailored to your needs.

- Comprehensive Quality Assurance: Our molds undergo strict quality checks at every stage of production, ensuring consistency, reliability, and optimal functionality.

- Industry Expertise: With years of experience serving industries such as plumbing, automotive, and bathroom fittings, we understand the unique requirements for creating reliable and long-lasting shower nozzle holders.

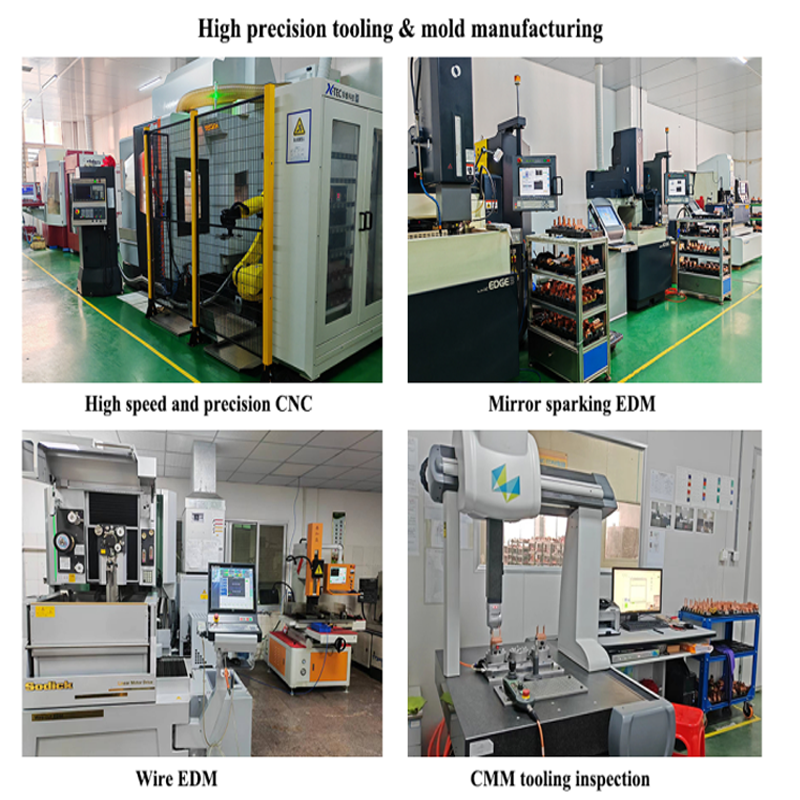

Factory Show:

Our manufacturing facility is equipped with the latest technologies to ensure the highest standards in mold fabrication. Our plant features CNC machining centers, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC) systems, ensuring exceptional precision and accuracy in mold production. With a fleet of 15 rubber compression molding presses and 2 LSR injection molding machines, we can handle both high-volume and custom projects efficiently. Our advanced inspection tools include 3D projectors, sealing testers, durometers, and elasticity gauges, all overseen by a dedicated team of certified quality control experts. We are fully certified to ISO 9001 and IATF 16949, ensuring reliable, high-performance manufacturing for all your molding needs.

Additionally, we integrate automated production lines, including AutoDryers, high-speed doming machines, and precision die-cutting equipment, to streamline processes, reduce lead times, and maintain consistent product quality. With a cleanroom environment for sterile production and a comprehensive quality control system, we guarantee the production of high-performance, precision-engineered molds that meet and exceed industry expectations.