Overview:

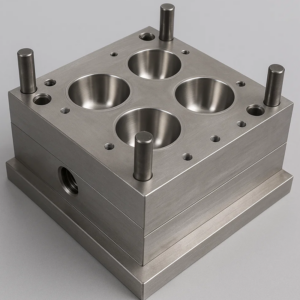

OEM Electroplating H13 Tooling Mold for Baby Care Cups Suppliers is a precision-engineered tooling solution designed to manufacture high-quality, durable baby care cups with superior surface finishes. Crafted from premium H13 tool steel, known for its excellent wear resistance and thermal stability, these molds are perfect for producing baby care products that meet rigorous safety and performance standards. Utilizing advanced technologies like CNC machining, EDM (Electrical Discharge Machining), and electroplating, our molds are designed to achieve micron-level precision, ensuring flawless production of intricate, high-performance parts. With an emphasis on electroplating for enhanced mold surface durability, we offer a reliable solution for creating smooth, safe, and long-lasting baby care cups. As an OEM manufacturer, we provide comprehensive one-stop services, from design and prototyping to full-scale production, ensuring your exact requirements are met with precision.

Basic Information:

| Specification | Details |

|---|---|

| Mold Type | Electroplating Tooling Mold |

| Mold Material Options | H13 Tool Steel |

| Mold Base Standards | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mold Runner System | Cold Runner / Hot Runner |

| Mold Gate Options | Slide Gate, Sub Gate, Pin-point Gate |

| Cavity | Single or Multi-Cavity |

| Design Software Supported | UG, PROE, CAD, SOLIDWORKS |

| Molding Equipment Used | CNC, Wire Cutting, EDM, Milling Machine |

| Compatible Raw Materials | Polypropylene (PP), Silicone, PVC |

| Packaging Method | Wooden pallet or custom packaging |

| OEM Services | Available — Please provide 2D/3D files or samples |

| Lead Time | Approximately 30 days |

| Surface Coating Options | Electroplating (Nickel, Chrome, etc.) |

Surface Coating Options:

- Electroplating (Nickel Plating): Enhances corrosion resistance, wear resistance, and improves mold longevity, making it ideal for high-performance baby care applications.

- Chrome Plating: Provides superior hardness and durability, extending tool life and enhancing surface aesthetics.

- Nickel-PTFE Coating: Reduces friction and prevents adhesion, ideal for applications involving materials with high thermal stability.

Benefits of Our Tooling:

- Precision-Matched Tooling Design

Advanced CNC machining and EDM (Electrical Discharge Machining) ensure micron-level accuracy (±0.005mm), guaranteeing seamless integration with raw materials for flawless baby care cup production. - Multi-Material Compatibility

Optimized venting systems and temperature-controlled channels enable flawless overmolding, combining multiple materials like silicone and PP, ideal for safe baby care product applications. - Electroplating for Extended Mold Life

Using Nickel or Chrome electroplating, our molds are highly resistant to wear, corrosion, and silicone adhesion, making them highly durable even after 500K+ cycles. - Rapid Cycle Time Optimization

Engineered cooling channels and automated ejection systems reduce cycle times by up to 30%, boosting productivity while maintaining consistent part quality.

Quality Assurance:

Our quality assurance process for OEM Electroplating H13 Tooling Molds includes a comprehensive testing protocol to guarantee that every mold meets global safety and quality standards. We follow stringent procedures outlined in ISO 9001 and IATF 16949, ensuring continuous product performance and defect-free output. Each mold undergoes rigorous verification using Mitutoyo CMM (Coordinate Measuring Machines) for dimensional accuracy and Keyence optical comparators for surface finish. Electrical performance and material integrity are confirmed with micro-ohm meters and Rockwell hardness testers. Mold flow simulations, CPK (Process Capability Index) analysis, and wear resistance testing ensure compliance with tight tolerances (±0.005mm). All molds undergo testing for thermal stability and ejection performance, ensuring reliability and safety in baby care product manufacturing.

Factory Show:

Our advanced manufacturing facility combines high-precision CNC machining centers, Mirror EDM, conventional EDM, and ultra-precise wire-cutting systems, ensuring exceptional mold accuracy and repeatability. On the production floor, we operate 15 rubber compression presses and 2 high-speed LSR injection molding units, optimizing both large-volume production and complex custom tooling with rapid cycle times and tight tolerances. All operations are certified to ISO 9001 and IATF 16949 standards, ensuring that every mold is made with the highest precision. We utilize 3D optical projectors, seal-integrity testers, Shore durometers, and elasticity gauges to perform exhaustive inspections at every process step. Our integration of automated AutoDryers, high-speed doming machines, and precision die-cutting further optimizes throughput, consistency, and product quality, ensuring reliable, high-performance tooling for the production of baby care products.