Description:

Our OEM High Precision P20 Silicone Rubber Compression Molding Tooling is designed for creating high-quality, durable silicone components used in kitchen and bathroom applications. Constructed from premium P20 tool steel, this mold delivers exceptional precision and strength to withstand the high demands of silicone compression molding. The addition of sandblasting treatment provides a superior surface finish, enhancing both functionality and aesthetics. Our tooling process ensures excellent cavity replication and part consistency, even for complex geometries.

From concept through prototyping and full-scale production, our turnkey molding solutions provide fast lead times and a scalable approach to meet the high-volume needs of the kitchen and bathroom industries. This comprehensive solution ensures superior quality, dimensional accuracy, and consistent silicone performance, with minimal cycle time and zero flash production.

![]()

![]()

Characteristics:

- Raw Materials: Food-grade silicone rubber, NSF, LFGB, FDA compliant

- Die Steel Grades: P20, H13 (optional for wear-resistant inserts)

- Runner System: Hot runner or cold runner

- Trademark/Branding: Fully customizable (logo engraving, cavity marking)

- Design Software: AutoCAD, UG, Pro/E, Moldflow analysis

- Certifications: ISO 9001, IATF 16949, FDA, RoHS, NSF

- Packaging: Wooden boxes with protective coating

- Annual Production Capacity: Up to 600 mold sets per year

- Color Options: Customizable for silicone final products

- Minimum Order Quantity: Small orders accepted

- Place of Origin: Xiamen, China

Benefits of Our Tooling:

- High Precision P20 tool steel for enhanced durability and surface quality.

- Sandblasting for a smooth, textured surface finish suitable for kitchen and bathroom applications.

- Customizable designs tailored to specific needs, ensuring perfect fit and performance.

- OEM support from prototyping to high-volume production.

Production Process:

- Material Selection & Compliance

Premium P20 tool steel is chosen for its hardness, resistance to wear, and excellent surface polishability. The silicone material meets FDA, LFGB, and NSF standards for food and medical-grade compliance. - Precision Mold Design

CAD/CAM-driven design ensures that the molds are optimized for compression molding, focusing on airtight sealing geometry, draft angles, and surface finish. Our design process includes Moldflow analysis to optimize filling, cooling, and stress distribution. - Prototype Validation

Pilot runs are conducted to validate dimensional accuracy using 3D CMM (Coordinate Measuring Machines), seal integrity, and material performance under actual conditions. Silicone flow and consistency are verified through pressure and leak testing. - High-Tolerance Mold Manufacturing

CNC machining and mirror EDM are used to create mold cavities and cores with micron-level precision. Sandblasting treatment is applied to enhance surface texture and achieve the desired finish for non-slip and aesthetic requirements. - Compression Molding & Post-Processing

Silicone rubber compression molding is performed under controlled conditions to ensure dimensional consistency. Post-processing includes deburring, ultrasonic cleaning, and laser trimming to ensure that all parts meet strict standards for kitchen and bathroom products. - Quality Assurance & Sterilization

All molded parts undergo 100% visual inspection, tensile strength checks, and dimensional verification. Any medical-grade silicone components are subject to biocompatibility tests. Products undergo post-molding sterilization if required (EtO or Gamma sterilization). - Traceability & Packaging

Our molds come with full traceability and are packaged in wooden crates to prevent damage during transit. Documentation complies with ISO standards and is ready for regulatory audits.

Quality Control:

Our quality control process ensures that all silicone rubber compression molds for kitchen and bathroom applications meet the most rigorous standards. The molds undergo precision dimensional checks using CMM (Coordinate Measuring Machines) and optical comparators. Additionally, sandblasting surface finishing is consistently controlled to ensure uniformity. Leakage tests and stress distribution analysis are conducted for high-quality silicone parts. Our ISO 9001 and IATF 16949 certifications guarantee that each tooling project undergoes the strictest manufacturing processes, ensuring excellent repeatability.

Factory Overview:

Our state-of-the-art manufacturing facility is equipped with:

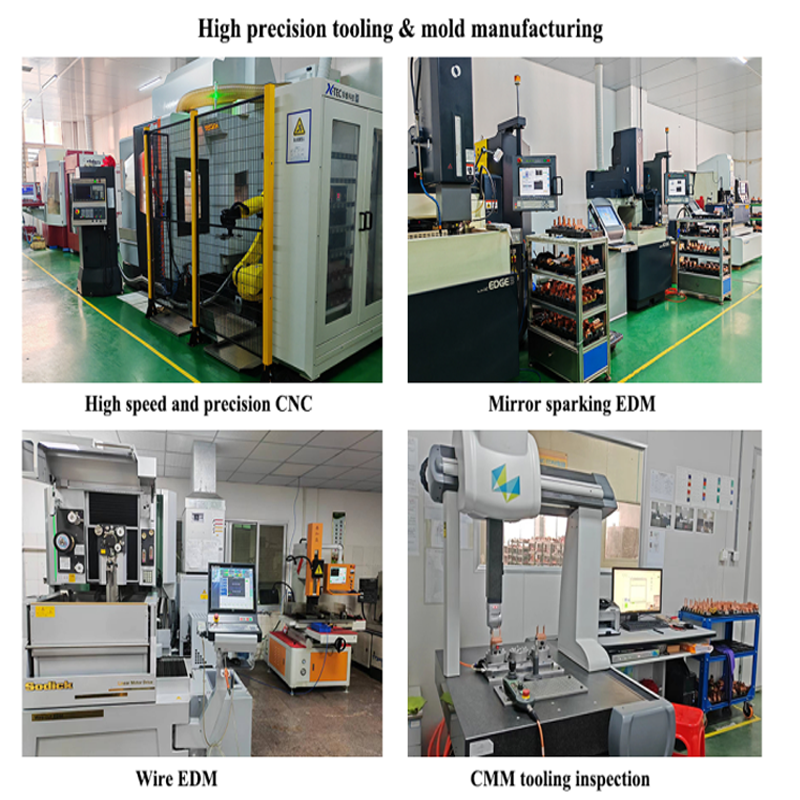

- CNC machining centers, mirror EDM, and precision wire EDM to ensure the highest mold accuracy and repeatability.

- 15 rubber compression molding presses and high-speed silicone injection molding machines to handle both prototype runs and large-volume production.

- Sandblasting stations to enhance the surface finish of silicone components.

- Automated inspection systems, including 3D optical projectors and sealing-integrity testers to ensure every part meets stringent specifications.

At our factory, we continuously aim for maximum efficiency by utilizing automated dryers, high-throughput doming stations, and precision die-cutting systems, allowing us to deliver high-performance silicone components that consistently exceed the most demanding industry standards.