Overview:

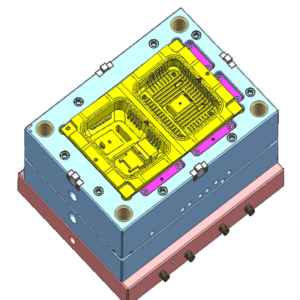

The Custom Plastic Battery Box Case Tooling Mould for the Automotive Industry is a precisely engineered solution designed to manufacture durable and high-performance battery box cases for vehicles. Constructed from premium materials like steel or aluminum, these molds utilize advanced injection molding technologies to achieve exceptional precision and operational efficiency. As seasoned manufacturers, we provide comprehensive one-stop services, offering custom-tailored solutions that meet your exact specifications while delivering cost-effective and reliable results. Our molds are designed to comply with the rigorous quality standards of IATF 16949, ensuring superior performance and long-lasting durability in every automotive application.

Characteristics:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Steel |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available |

| Certification | ISO9001, IATF16949 |

| Packaging | Custom |

| MOQ | According to your requirement |

| Lead Time | 25-30 days |

Surface Treatment Options:

- Nickel Plating: Provides exceptional corrosion resistance and durability, significantly extending the mold’s lifespan in demanding automotive environments.

- Hard Anodizing: Increases surface hardness and wear resistance, making it well-suited for high-precision automotive molding applications.

- Chromium Plating: Delivers superior protection against wear and corrosion, ensuring long-term, consistent mold performance.

- Polishing: Refines the surface finish of the tooling, reducing friction during the molding process and enhancing the quality of the molded components.

Quality Assurance:

Our quality assurance process for Custom Plastic Battery Box Case Tooling Moulds for the Automotive Industry is based on stringent standards and thorough testing protocols. With ISO 9001 and IATF 16949 certifications, we ensure compliance with top-tier quality management systems. Our robust inspection process includes first-article evaluations, in-process audits, and final product assessments. To ensure accuracy, we employ advanced testing tools such as coordinate measuring machines (CMM), hardness testers, and surface roughness analyzers to verify precise dimensions and material integrity. Additionally, our automated vision systems and comprehensive material testing guarantee the consistency, reliability, and durability of each mold we produce.

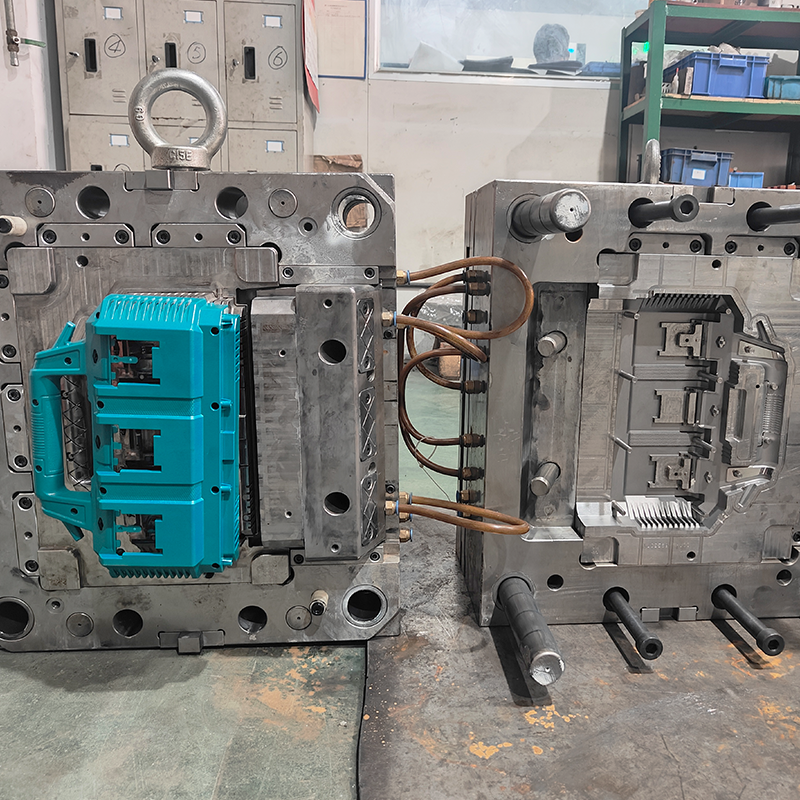

Factory Show:

Our advanced manufacturing facility is equipped with the latest technologies, including CNC machining, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC), enabling the highest levels of precision in mold fabrication. With 15 rubber compression molding presses and 2 LSR injection molding machines, we efficiently scale production while ensuring consistent and optimal performance. To uphold industry-leading standards, we utilize state-of-the-art inspection tools such as 3D projectors, sealing testers, durometers, and elasticity gauges, all managed by our certified quality control team. Fully compliant with ISO 9001 and IATF 16949 certifications, we ensure reliable, high-performance manufacturing. Additionally, automation systems like AutoDryers, high-speed doming machines, and precision die-cutting technology further enhance productivity, precision, and product quality, maintaining consistency throughout every stage of production.