Overview:

Our custom plastic infant bathtub mold tooling represents the pinnacle of precision engineering, purpose-built for safe, ergonomic baby bath production via injection molding. Constructed from premium pre-hardened tool steels, stainless steels, or aluminum alloys, each mold is finished through precision CNC machining, EDM, and mirror polishing to achieve impeccable surface quality and exacting dimensional tolerances. As a full-service OEM partner, we guide your project from initial concept and CAD design through prototype validation and full-scale production. Leveraging cutting-edge equipment and workflow optimization, our FDA-compliant molds deliver both high-volume throughput and small-batch agility. Rely on our expertise to develop bespoke tooling solutions that uphold the highest standards of quality, safety, and accelerated time-to-market.

Features:

- Place of Origin:Xiamen, China

- Brand Name:OEM

- Product Material:Plastic

- Certifications:ISO, FDA

- Cavity Configuration:Fully custom

- Design Options:2D or 3D

- Runner System:Cold runner

- Mold Steel Grades:P20H, 718, 2316, 2738, and others

- Mold Lifespan:500,000–1,000,000 shots

- Sample Lead Time:45–60 days

Benefits of Our Tooling:

- Superior Material Durability: Moulds crafted from hardened steel (e.g., NAK80, S136) or aluminum alloys ensure 500k+ injection cycles, resisting wear, corrosion, and deformation for long-term consistency.

- Precision-Grade Design: CNC-machined cavities with ±0.02mm tolerance and gas-assisted ejection systems guarantee seamless demolding, eliminating surface defects (sink marks, flashes) on bathtubs.

- Efficient Cycle Time Optimization: Conformal cooling channels and automated hot-runner systems reduce cycle times by 20-30%, enhancing output while maintaining energy efficiency.

- Compliance-Driven Safety: Moulds are engineered to meet FDA, EN 71, and ISO 13485 standards, with integrated venting systems to prevent material degradation and ensure non-toxic, baby-safe finishes.

Production Process:

- Design & Simulation: 3D CAD modeling and Moldflow analysis optimize mold geometry for uniform wall thickness, minimal warpage, and efficient material flow to meet ASTM F963 and EN 71 safety standards.

- Material Selection & Machining: High-performance steel (NAK80, S136) or aluminum alloy blocks are CNC-milled, EDM-textured, and polished to mirror-grade finishes (Ra ≤0.1μm) for defect-free part ejection.

- Mold Assembly & Debugging: Integrated hot-runner systems, conformal cooling channels, and lifter mechanisms are calibrated to ensure ±0.03mm dimensional accuracy and cycle times under 30 seconds.

- Trial Injection & Validation: Pilot production runs using FDA-approved PP or TPE materials verify mold performance, with CMM checks, sink mark analysis, and infant-safety edge testing.

- Surface Treatment & Certification: Molds undergo nitriding or PVD coating for wear resistance, followed by ISO 13485-compliant documentation and RoHS/REACH material certification.

- Mass Production Readiness: Final tooling is paired with automated IMMs (80-400T clamping force) for high-volume output, supported by in-line AOI systems for real-time defect detection.

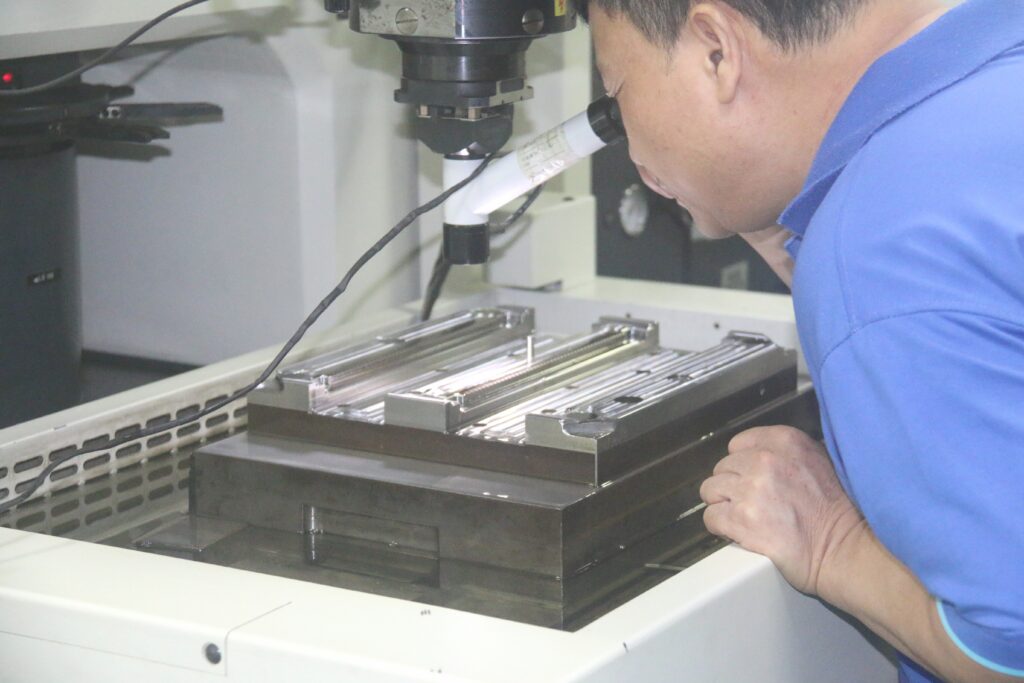

Factory Show:

Our advanced manufacturing campus features state-of-the-art CNC machining centers, mirror and conventional EDM, and ultra-precise wire-cutting systems—delivering molds with unmatched accuracy, consistency, and repeatability. On the production floor, fifteen rubber compression presses and two high-speed LSR injection units handle both large-volume runs and intricate custom tooling, ensuring rapid cycle times and exacting tolerances. Under ISO 9001 and IATF 16949 oversight, our veteran quality engineers employ 3D optical projectors, sealing-integrity testers, Shore durometers, and elasticity gauges to perform exhaustive inspections at every stage. Complementary automation—AutoDryers, high-throughput doming stations, and precision die-cutters—further standardizes processes. The result is a seamless, fully integrated operation that consistently delivers performance-critical components exceeding the most rigorous industry benchmarks.