Overview

Our custom tooling molds precision compression molds for durable silicone cylinder bellows. Engineered from premium steels with CNC and EDM machining, they ensure exacting concentricity and wall thickness. We provide complete OEM solutions, from design to tooling, for reliable production of flexible, leak-proof protective bellows for automotive, industrial, and medical applications.

Basic Information

| Attribute | Details |

|---|---|

| Mold Type | Silicone Rubber Compression Mold |

| Mold Material | 4140/4340 Steel, H13, Stainless Steel (420, 440C) |

| Mold Base Standards | LKM, HASCO, DME, Custom |

| Core/Cavity Process | CNC Machining, Wire-EDM, Jig Grinding |

| Mold Design Focus | Concentricity Control, Draft Angles, Venting for Air Traps |

| Design Software Supported | UG NX, SolidWorks, AutoCAD |

| Compatible Material | Solid/HCR Silicone Rubber (Various Hardness) |

| Curing System | Electric/Steam Heated, Water Cooled |

| Packaging Method | Heavy-Duty Wooden Case |

| OEM Services | Available (Provide 2D/3D drawings or sample part) |

| Lead Time | Approximately 35-45 Days |

Surface Coating & Treatment Options

-

High-Gloss Polish (SPI A1/A2): Achieves an optical-quality finish on the mold cavity for producing bellows with very smooth, low-friction surfaces, facilitating demolding.

-

PTFE-Impregnated Nickel Coating: A low-surface-energy coating that significantly improves silicone release, reduces mold fouling, and minimizes the need for external release agents.

-

Hard Chrome Plating: Increases surface hardness and corrosion resistance of the mold cores, extending tool life when processing abrasive or heavily pigmented silicone compounds.

-

Titanium Nitride (TiN) Coating (PVD): Provides extreme surface hardness and excellent wear resistance for high-volume production runs, protecting critical sealing edges.

Benefits of Our Tooling for Cylinder Bellows

-

Engineered for Precision & Repeatability: Our molds are built with a focus on absolute concentricity between inner and outer cores, ensuring uniform wall thickness and consistent compression set performance in every bellow produced.

-

Optimized for Efficient Demolding & Venting: Strategic vent placement and carefully calculated draft angles are integrated into the design to prevent air traps and facilitate the easy removal of the deep, undercut bellow shape without tearing.

-

Robust Construction for Long Production Life: Utilizing hardened tool steels and wear-resistant surface treatments, our molds withstand the high clamping pressures and continuous thermal cycling of compression molding, ensuring longevity over hundreds of thousands of cycles.

-

Designed for Material Efficiency & Fast Cure: The mold cavity volume is precisely calculated to minimize silicone flash and waste. Efficient heating/cooling channel layouts promote rapid, uniform curing, optimizing cycle times for cost-effective production.

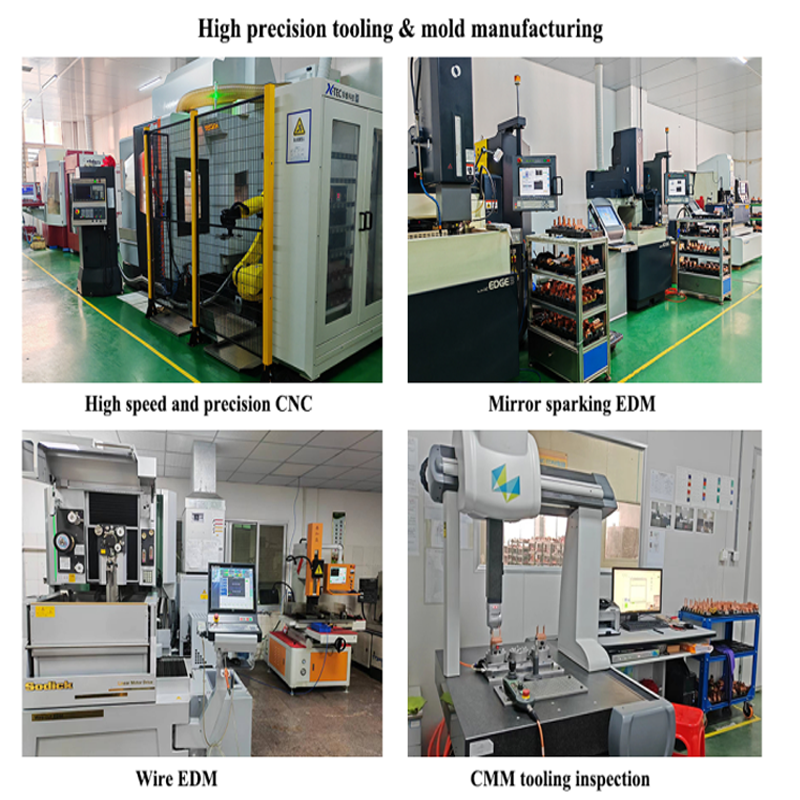

Factory Show

Our mold-making workshop is equipped with advanced 5-axis CNC machining centers, precision jig grinders, and CNC Wire-EDM machines capable of fabricating the complex, concentric core sets required for bellow molds. We employ state-of-the-art CAD/CAM software for design and simulation. Quality is verified at every stage using laser scanners, coordinate measuring machines (CMM) for concentricity checks, and digital profilometers for surface finish analysis. Operating within an ISO 9001 certified quality management system, our integrated process—from steel sourcing to final tool tryout—ensures the delivery of durable, high-precision compression molds that produce reliable silicone cylinder bellows.