Overview:

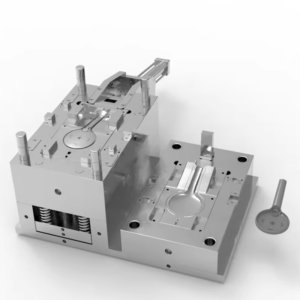

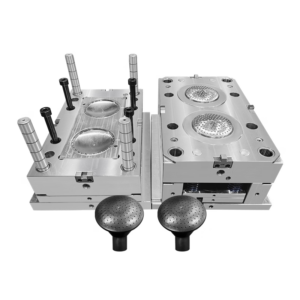

The OEM Steel and ABS Injection Mould Tooling Mold for Plastic Shower Heads is a high-precision tooling system designed to produce durable, functional, and aesthetically pleasing plastic shower heads. These molds are crafted from premium materials such as P20, 718, and 2738 steel, ensuring excellent durability and long-term performance under high-cycle manufacturing conditions. Utilizing advanced EDM (Electrical Discharge Machining) and CNC machining techniques, we deliver molds that guarantee tight tolerances, superior surface finishes, and optimized efficiency in production. Our expertise allows us to provide fully customized, OEM-grade molds tailored to your specific design needs, ensuring that your plastic shower heads meet both functional and aesthetic requirements.

This mold system is designed for both hot and cold runner systems, offering versatility and efficiency in the production process. Whether for large-scale production runs or small-batch custom tooling, we provide mold solutions that cater to a variety of needs in the plastic injection molding industry.

Basic Information:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | Steel, ABS |

| Certification | ISO 9001, FDA |

| Cavity | Custom |

| Design | 2D or 3D |

| Runner Type | Hot/Cold Runner |

| Mould Steel | P20H, 718, 2738, 2316, etc. |

| Mould Life | 500,000–1,000,000 shots |

| Sample Time | 45–60 days |

Key Features & Benefits:

- Custom-Designed Tooling:

Our molds are designed based on your specific requirements for plastic shower head production, including custom cavity design, runner system (hot or cold), and material selection. This ensures that each part meets functional, aesthetic, and performance requirements. - Precision Manufacturing:

Using EDM and CNC machining, we ensure superior mold accuracy, including intricate details and complex geometries, delivering flawless results that improve the part quality and reduce cycle time. - Enhanced Durability:

Crafted from high-grade steel and ABS, our molds are built for long-lasting performance. We ensure that molds are capable of withstanding high-volume production, with a mold life ranging from 500,000 to 1,000,000 shots, providing a cost-effective solution for mass manufacturing. - Hot/Cold Runner Options:

Offering flexibility in the molding process, our molds are designed to work with both hot runner and cold runner systems. This adaptability allows for optimized material flow, reduced waste, and faster cycle times while ensuring consistent quality in the molded parts.

Surface Treatment Options:

- Hard Chrome Plating: Provides wear resistance and a smooth surface, reducing part sticking and ensuring easy part ejection.

- Electroless Nickel Plating: Offers uniform corrosion protection, extending mold life and performance in the harshest conditions.

- PVD Titanium Nitride (TiN) Coating: Enhances abrasion resistance, reduces friction, and improves mold longevity.

- Diamond-Like Carbon (DLC) Coating: Ensures superior hardness and ultra-low friction, further increasing the mold’s performance and lifespan.

Quality Assurance:

Our commitment to quality is evident in our comprehensive quality assurance process. Each mold is designed and manufactured under ISO 9001 and IATF 16949 standards, ensuring precision and compliance with the highest industry expectations. Our quality control team uses advanced testing equipment, including coordinate measuring machines (CMM), hardness testers, surface roughness analyzers, and electrical conductivity testers to verify every aspect of the mold’s performance.

All molds are subjected to detailed inspection protocols, ensuring that they meet dimensional accuracy and surface finish specifications. Every mold undergoes thorough traceability checks, allowing us to guarantee compliance with industry regulations and provide the highest level of reliability and safety for mass production.

Factory Show:

Our manufacturing facility is equipped with advanced machinery to ensure precision and efficiency throughout the production process. CNC Machining Centers enable high-precision milling and shaping of mold components, while Mirror EDM and Conventional EDM are used for intricate, high-detail work on mold cavities, ensuring smooth and flawless mold surfaces. For ultra-precise cuts and tight tolerances in complex geometries, we employ wire-cutting systems. Our injection molding machines, featuring both hot and cold runner systems, offer flexibility to meet varying production needs. To maintain stringent quality standards, we also utilize 3D optical projectors, sealing-integrity testers, Shore durometers, and elasticity gauges, ensuring quality control across every phase of production.