In the world of precision manufacturing, CNC milling stands out as one of the most efficient and accurate methods for producing high-quality parts and prototypes. Whether you’re working on complex designs for aerospace, automotive, or consumer products, CNC milling allows for incredible detail and precision. However, to truly unlock the potential of CNC machining, it is critical that your CAD model is optimized for the process. At Toolingsun, we specialize in CNC milling services and are here to share expert tips for preparing your CAD models to ensure that your designs translate seamlessly into high-precision parts.

Before your design is brought to life, it must be carefully prepared and refined to align with CNC milling best practices. Here’s a detailed guide to the most important factors to consider when designing your CAD model for CNC milling.

1. Understanding the CNC Milling Process and the Role of CAD Models

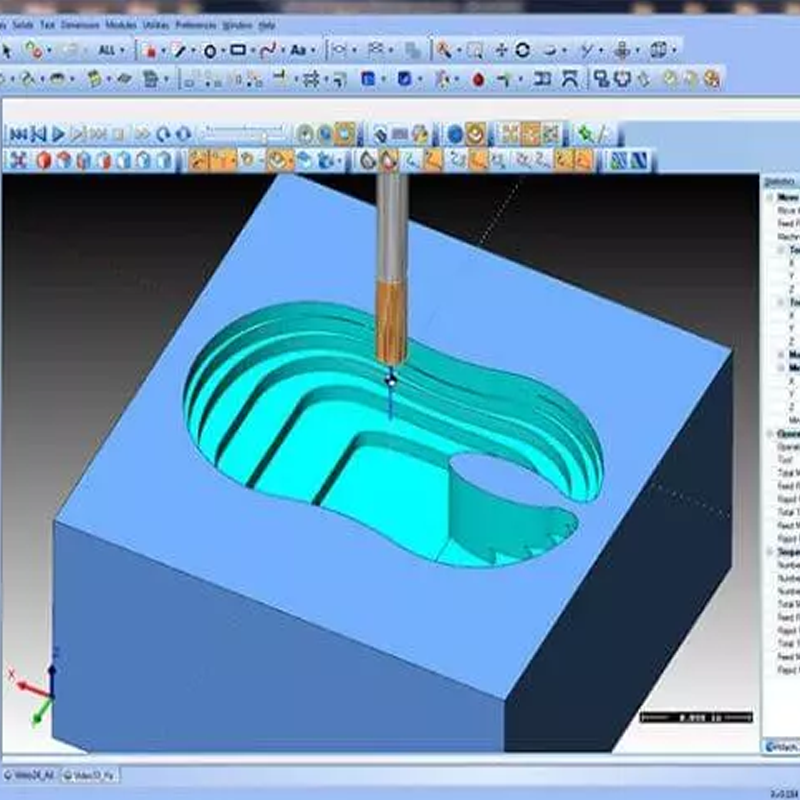

CNC milling uses rotating cutting tools to shape material into precise dimensions based on digital designs. Your CAD model forms the blueprint for this process, and a well-prepared design ensures a smooth transition from digital concept to physical part. The process begins by converting your CAD file into a machine-readable format, such as DXF or DWG, which is then imported into CAM (Computer-Aided Manufacturing) software. From here, the software generates G-code that directs the CNC machine’s movements, translating the design into a finished part.

However, the path from CAD model to CNC part is not always straightforward. Even minor issues in the CAD design can result in costly errors and delays. Here are some critical tips to ensure that your design is CNC-friendly, ensuring a smooth, efficient, and cost-effective production process.

2. Optimizing Your Design for CNC Milling

Cavities, Edges, Walls, and Holes:

One of the first steps in optimizing a CAD model for CNC milling is ensuring that cavities, edges, walls, and holes are designed with machining limitations in mind. CNC machines have limitations on the depth and diameter of cavities, so it’s essential to optimize these features early on to prevent production delays.

- Cavities: Avoid making cavities too deep relative to the diameter of the tool, as most end mills can only cut to a depth of 3-4 times their diameter.

- Edges: Internal corners and sharp edges need special attention. For high-quality surface finishes, aim for radii that are at least 1mm larger than the cutting tool’s diameter.

- Wall Thickness: Thin walls can result in weak parts that are prone to deformation during milling. For metals, aim for wall thicknesses of at least 0.8mm, and for plastic parts, 1.5mm or thicker.

- Holes: When creating holes in your design, consider the drilling capabilities of the machine. For high-precision holes, reamers or boring tools may be required to achieve the desired tolerances.

Optimizing the Geometry for CNC Milling:

After addressing the basic design features, you’ll want to streamline your geometry to avoid unnecessary complexity in the milling process.

- Avoid Overlapping Geometry: When vectors overlap in your CAD design, the CNC machine will make multiple passes over the same area. Eliminate duplicate lines or overlapping sections to ensure that the machine works efficiently and reduces unnecessary tool wear.

- Use Simple Layers: When preparing your CAD file, organize your model into the fewest possible layers. This reduces the complexity of the design, making it easier for the CNC machine to process.

Proper Scaling and Tolerances:

Ensuring that your design is properly scaled is crucial for achieving high precision during CNC milling. Work in millimeters and maintain tolerances of 0.5 microns or less, which is standard in high-precision machining. Many CAM systems will automatically scale your model, but it’s always best to confirm that the scaling is correct before sending the file to the machine.

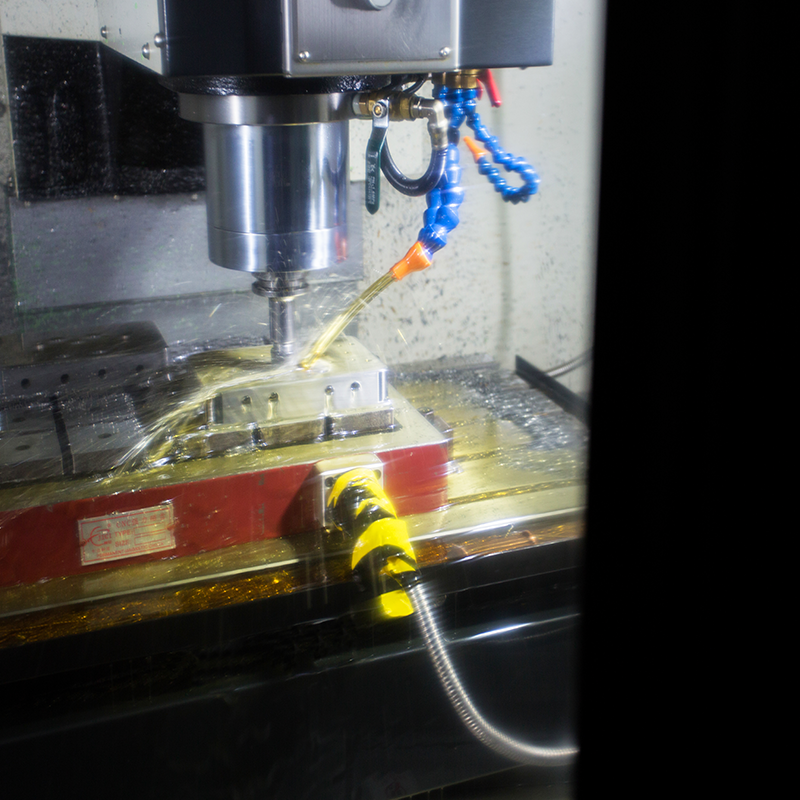

3. Choosing the Right Materials for CNC Milling

The choice of material is one of the most important aspects of preparing a CAD model for CNC milling. Whether you’re working with metals, plastics, or composites, each material requires specific considerations during the design and manufacturing process.

- Metals: For metal components, it’s important to account for the material’s hardness and the cutting tool’s ability to handle it. Aluminum and steel are common materials, but harder materials like titanium or hardened steel may require more specialized tools and machining methods.

- Plastics: When designing for plastic parts, consider material flexibility, shrinkage, and thermal expansion. Polymers like ABS, PEEK, and polycarbonate all behave differently during machining and can require specialized feeds and speeds.

- Composites: Composite materials require special attention due to their unique properties, such as layering and fiber direction. Ensure that your design takes these factors into account to optimize the CNC milling process.

At Toolingsun, we offer a wide range of materials suitable for CNC milling, from high-precision metals like aluminum and stainless steel to plastics and composites. Our team of experts can help you choose the right material based on your project requirements.

4. Integrating Text and Branding into Your Design

If you plan on including branding or text in your design, there are some best practices to follow to ensure clarity and precision in the final product.

- Text Size: Keep text legible by using clear fonts like Arial or Sans-Serif, and ensure that individual characters have at least 0.5mm of spacing between them.

- Recessed Text: For logos or part numbers, ensure that text is recessed into the part to avoid issues with tooling and clarity.

5. Testing and Refining Your Design for Optimal Results

After preparing your CAD model for CNC milling, it’s essential to test and refine your design before full-scale production. This involves creating prototypes or samples, ensuring that the design functions as intended, and identifying any issues that may arise during the milling process.

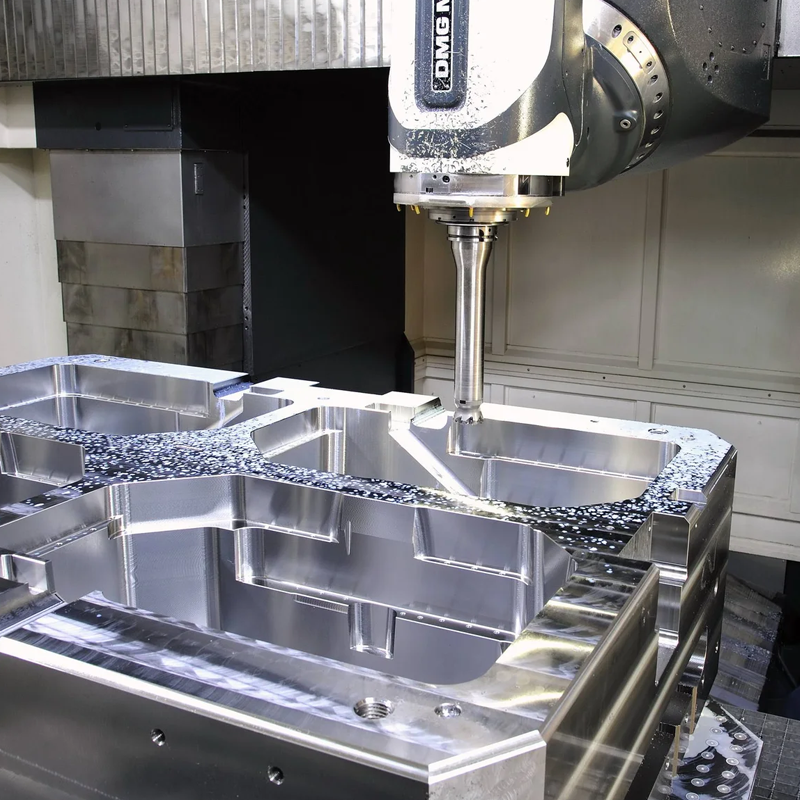

At Toolingsun, we specialize in both rapid prototyping and large-scale manufacturing, giving you the flexibility to test your designs before committing to mass production. We use professional-grade CNC machinery and experienced staff to ensure that your designs are produced with high precision and exceptional quality.

Conclusion

Optimizing your CAD model for CNC milling is a crucial step in ensuring the success of your project. By following these tips and best practices, you can avoid costly mistakes, ensure high precision, and improve the overall performance of your final product. At Toolingsun, we pride ourselves on offering high-quality, high-precision CNC machining services. Whether you need a prototype for a new design or require mass production capabilities, our experienced team is here to help.

Our factory is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, ensuring that your designs are turned into high-quality products with accuracy and efficiency. We also offer OEM services and custom solutions tailored to meet your specific needs.

If you’re ready to take your design to the next level, contact Toolingsun today to discuss how our CNC milling services can help bring your vision to life. Whether you need a one-off prototype or large production runs, we have the tools and expertise to make it happen.