Titanium is one of the most sought-after materials in manufacturing today. Known for its superior strength-to-weight ratio, corrosion resistance, and high temperature tolerance, titanium is used in industries where performance and durability are critical. Whether you’re in aerospace, medical, automotive, or defense, titanium CNC machining is essential for creating high-precision parts. At Toolingsun, we specialize in providing top-quality titanium machining services and offer one-stop solutions for all your manufacturing needs. This guide will walk you through the types of titanium alloys used in CNC machining, their applications, and best practices to ensure you get the best results.

Why Choose Titanium for CNC Machining?

Titanium alloys are a popular choice in CNC machining due to their outstanding physical properties. Some of the key reasons titanium is so widely used include:

- Strength-to-Weight Ratio: Titanium is known for being incredibly strong while still being lighter than many other metals, making it ideal for applications where weight savings are critical, such as aerospace and automotive industries.

- Corrosion Resistance: Titanium forms a protective oxide layer that makes it highly resistant to corrosion, even in harsh environments like saltwater and extreme chemical exposure. This makes it perfect for marine, medical, and chemical processing applications.

- High-Temperature Performance: Titanium maintains its strength even at high temperatures, which is why it’s used in components that will be exposed to extreme conditions, such as aircraft engines and industrial turbines.

At Toolingsun, we provide custom services to ensure your titanium parts are machined to the highest standards, helping you achieve the precise and durable results you need for your application.

Common Titanium Alloys for CNC Machining

Titanium alloys are classified into different categories based on their composition and the properties they offer. These include alpha, beta, and alpha-beta alloys. Below are some of the most commonly used titanium alloys in CNC machining:

1. Grade 5 Titanium (Ti-6Al-4V)

Characteristics:

Grade 5 titanium, also known as Ti-6Al-4V, is the most commonly used titanium alloy. It contains 6% aluminum and 4% vanadium, with the balance being titanium. This alloy is known for its high strength, low weight, and exceptional corrosion resistance. It’s also heat treatable, allowing manufacturers to improve the mechanical properties as needed.

Applications:

- Aerospace: Used in components such as turbine blades, fuselage parts, and wings.

- Medical: Ideal for dental implants, orthopedic prosthetics, and surgical instruments.

- Marine: Used for fasteners, propellers, and other parts exposed to saltwater.

- Automotive: Applied in exhaust systems and engine components.

Machining Considerations:

Due to its high strength, Grade 5 titanium can be difficult to machine. The material’s hardness can cause significant wear on tooling, so it’s essential to use high-quality cutting tools and efficient cooling systems. Toolingsun uses the latest CNC technology and materials to ensure precise machining while minimizing tool wear and heat generation.

2. Grade 2 Titanium

Characteristics:

Grade 2 titanium is commercially pure titanium (CP titanium) with no alloying elements. It offers excellent corrosion resistance and good formability, making it easy to work with compared to Grade 5 titanium.

Applications:

- Chemical Processing: Used in reactors, heat exchangers, and tanks.

- Marine Hardware: Ideal for fasteners, boat hulls, and propellers.

- Medical: Used for implants and surgical instruments.

Machining Considerations:

Grade 2 titanium is relatively easier to machine than Grade 5 due to its lower strength, but it still requires careful cutting speeds and proper lubrication to avoid wear. At Toolingsun, we ensure that the machining process is optimized for efficiency and durability.

3. Grade 23 Titanium (Ti-6Al-4V ELI)

Characteristics:

Grade 23 is an extra-low interstitial (ELI) version of Grade 5 titanium, offering improved ductility and fracture toughness. It has a lower oxygen content than Grade 5, which enhances its resistance to brittleness.

Applications:

- Aerospace: Used for high-performance aerospace components.

- Medical: Essential for dental and orthopedic implants due to its superior biocompatibility.

- Defense: Applied in high-stress components that require toughness and strength.

Machining Considerations:

Grade 23 requires precision machining, as it can be more forgiving than Grade 5, but it still needs careful control of cutting speeds and cooling to prevent excessive tool wear.

4. Grade 9 Titanium (Ti-3Al-2.5V)

Characteristics:

Grade 9 is an alpha-beta alloy that contains 3% aluminum and 2.5% vanadium. It provides a good balance of strength, formability, and corrosion resistance. This alloy is lightweight compared to other titanium alloys, making it ideal for applications where weight is a primary concern.

Applications:

- Aerospace: Frequently used in lightweight aerospace components such as wings and landing gears.

- Automotive: Ideal for racing cars and other high-performance vehicles.

- Sporting Equipment: Used in high-performance sporting equipment like bicycles and golf clubs.

Machining Considerations:

Grade 9 titanium is easier to machine than Grades 5 and 23. However, precision control over cutting speeds, lubrication, and tool materials is still necessary to ensure a high-quality finish.

CNC Machining Process Flow for Titanium

The CNC machining process for titanium alloys is detailed and requires careful control at each stage to ensure optimal results. Here’s an overview of the typical process flow:

- Material Selection: The right titanium alloy must be chosen based on the desired strength, corrosion resistance, and fatigue resistance for the application.

- Designing and Programming: A CAD model of the part is created and transformed into CNC instructions. The design must consider titanium’s unique properties, such as its low thermal conductivity and tendency to work-harden.

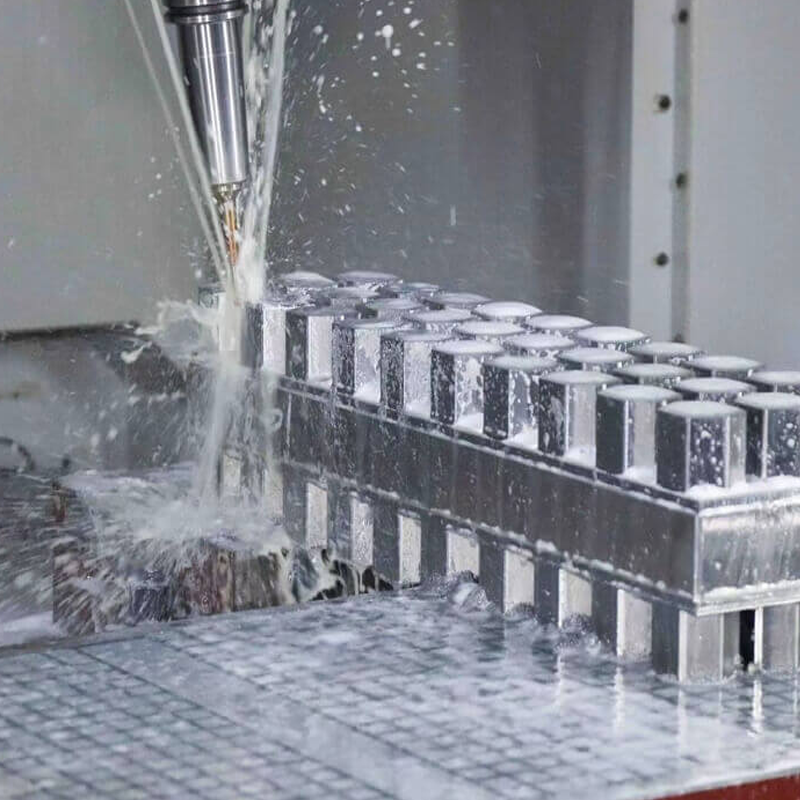

- Tool Selection and Setup: Titanium requires specialized tools made from carbide or ceramic to withstand its hardness. Choosing the right tools ensures that the machining process is efficient and reduces tool wear.

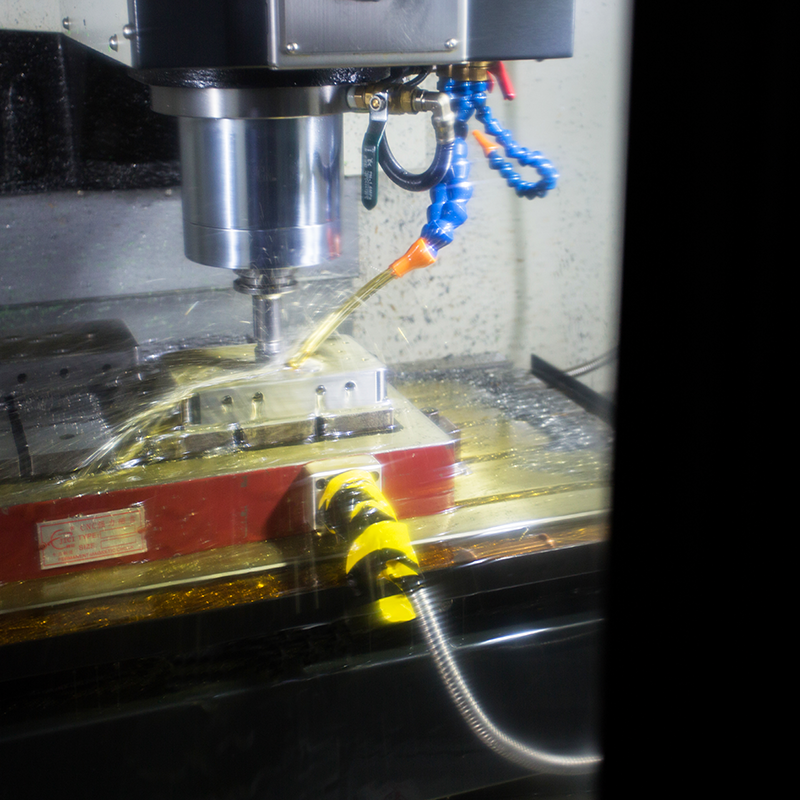

- Machining Operations: The operations typically include rough cutting, drilling, and finishing. Titanium’s heat sensitivity requires precise control of cutting speeds and the use of high-quality cooling fluids to prevent overheating.

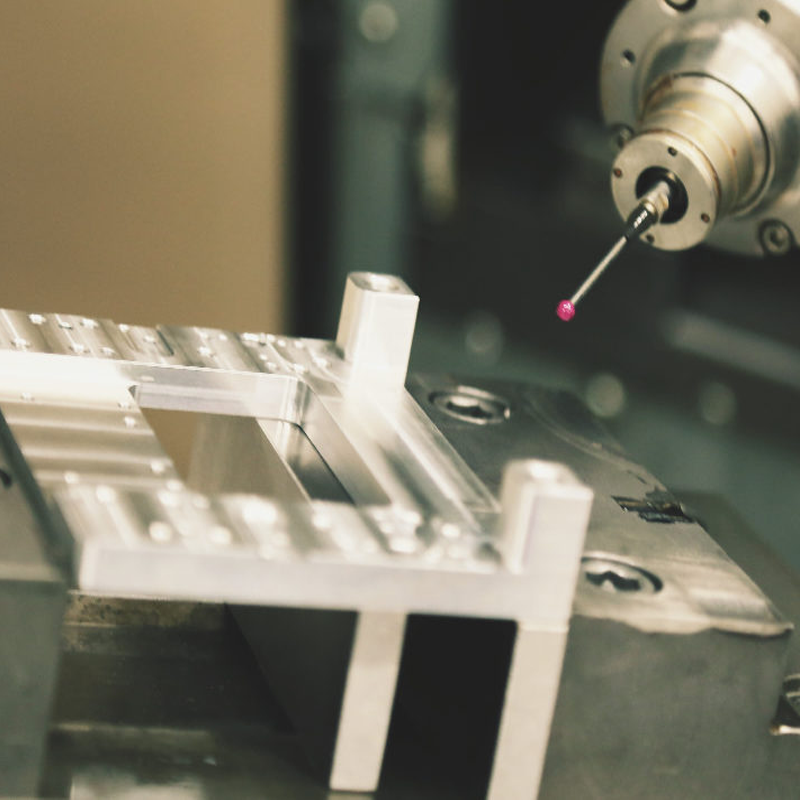

- Inspection: After machining, the parts undergo thorough inspection to ensure dimensional accuracy and surface finish. Titanium’s low thermal conductivity means that warping can occur, so consistent monitoring is essential.

- Post-Processing: Treatments such as coating, anodizing, or polishing may be applied to enhance corrosion resistance and improve surface finish properties, depending on the end-use requirements.

Titanium vs. Other Metals in CNC Machining

Titanium is often compared to other metals, such as aluminum and steel, due to its high strength and unique properties.

- Strength-to-Weight Ratio: Titanium offers a unique balance of strength and lightness, superior to aluminum in many cases, and comparable to steel. This makes titanium ideal for high-performance applications, such as aerospace and automotive.

- Corrosion Resistance: Titanium outperforms both aluminum and steel in terms of corrosion resistance, especially in environments exposed to saltwater or industrial chemicals. This makes it perfect for marine and medical applications.

- Machinability: Titanium’s low thermal conductivity makes it more challenging to machine than aluminum or steel. However, with the right tools and processes, it can be machined efficiently to tight tolerances.

Why Choose Toolingsun for Your Titanium CNC Machining Needs?

At Toolingsun, we are proud to be your trusted partner in titanium CNC machining. Our team of experts has decades of experience working with various titanium alloys, ensuring that each part meets the highest quality standards. We offer custom services that cater to your unique project needs and provide a one-stop service to streamline your manufacturing process.

Our state-of-the-art factory is equipped with the latest CNC machining technology, which enables us to handle complex titanium components with ease. Whether you’re in aerospace, medical, automotive, or any other industry, we are equipped to provide you with precise, durable, and high-quality titanium parts.

If you’re looking to manufacture titanium components, Toolingsun is here to help. Contact us today to learn more about how our custom services and expertise can benefit your project. Let us help you achieve precision, performance, and durability with titanium CNC machining.