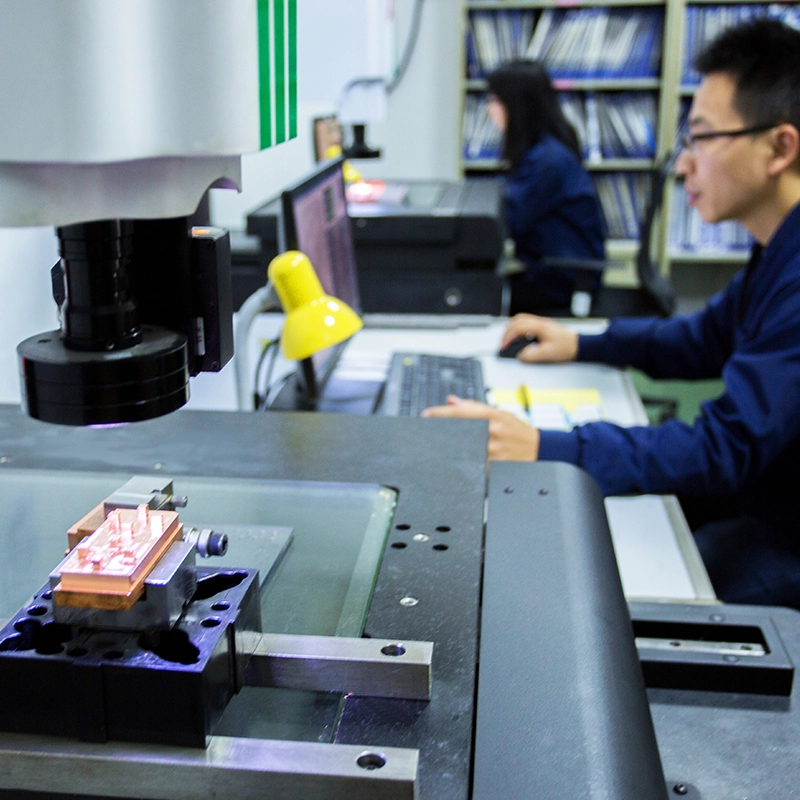

At Toolingsun, a precision-focused manufacturer and factory serving global OEMs and suppliers, we rely on Coordinate Measuring Machine (CMM) inspection every day to guarantee part accuracy and traceability. Whether you’re validating a new prototype or running final inspection on production lots, CMM inspection provides the reliable, traceable measurements engineers need to control quality and accelerate time to market. Below is a practical, professional guide that explains what 3D CMM measurement is, how a standard inspection workflow runs, where it’s most useful, and when CMM is the right tool for your program.

What Is 3D CMM Measurement

3D CMM measurement uses a tactile probe or non-contact sensor mounted on a precise coordinate machine to capture discrete XYZ coordinates across a part’s surface. Modern CMMs combine high-accuracy kinematics, temperature compensation, and advanced software to compute form, position, and profile relative to CAD models or drawing datums. Results include true 3D geometry comparisons, GD&T evaluations, and full dimensional reports that support engineering decisions and supplier quality assurance.

The Standard CMM Inspection Workflow

A reliable CMM program follows a disciplined workflow to ensure repeatable results and traceability.

Environmental and Equipment Readiness Verification

Before measuring, verify room temperature, humidity, and vibration limits. Calibrate the CMM probe and perform periodic machine verification using certified artefacts to confirm volumetric accuracy.

Part Preparation and Fixturing Validation

Inspect the part for surface contaminants, burrs, or deformation. Secure repeatable fixturing and datum references to minimize variation. Proper fixturing is as critical as the CMM itself for consistent outcomes.

Inspection Program and Datum Alignment Review

Load an inspection program derived from CAD or develop a probe path that captures critical features efficiently. Confirm datum strategy matches drawing requirements and establishes traceability to standards.

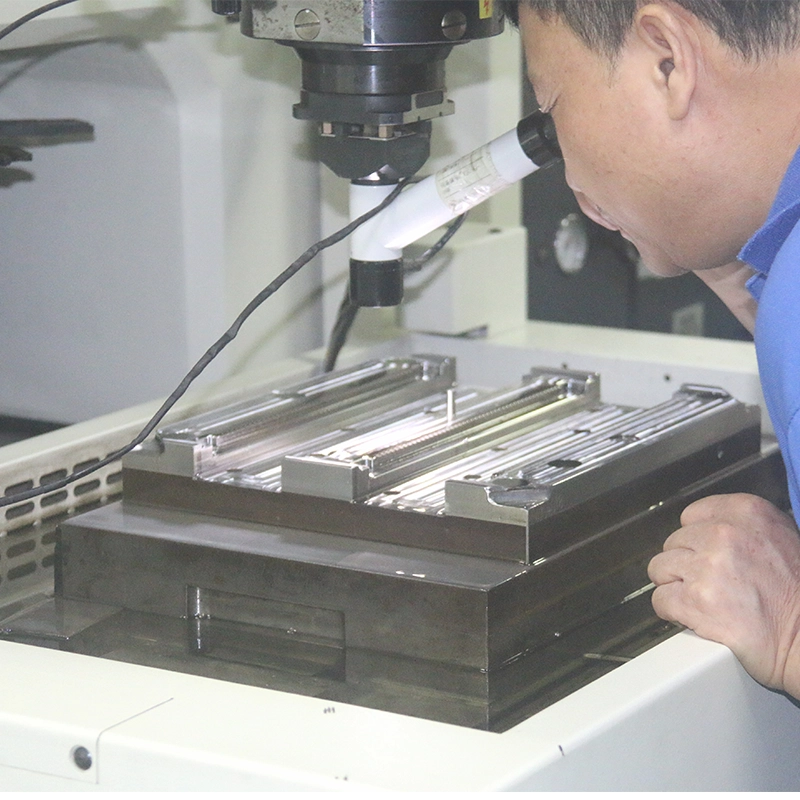

Execution and Measurement Control

Run the program in automatic or manual modes. Monitor probe contacts, stylus deflection, and any dynamic errors. For complex geometries, combine tactile runs with non-contact scanning to capture freeform surfaces.

Measurement Data Validation and Analysis

Validate data against nominal CAD models and GD&T tolerances. Flag out-of-spec features, compute process capability indices (Cp/Cpk), and correlate measurement deviations to potential manufacturing process issues.

Reporting, Documentation, and Traceability

Generate comprehensive inspection reports that include measurement results, pass/fail status, probe calibration records, and traceability to standards. Store reports in a QA system for audit and supplier communication.

Manufacturing Processes Applicable to CMM Inspection

CMM inspection is essential across common production technologies:

CNC Machining

Critical for verifying tight dimensional tolerances, concentricity, and complex multi-axis features.

Injection Molding

Used to check cavity-to-cavity variation, wall thickness, and molded feature locations versus CAD.

Die Casting

Validates shrinkage compensation, draft angles, and post-machining datum relationships.

Why Invest in CMM Inspection?

Improved Measurement Accuracy and Repeatability

CMMs measure features to micron-level precision with stable repeatability, reducing ambiguity in acceptance decisions.

Reduction of Scrap, Rework, and Production Waste

Early detection of deviations prevents large volumes of off-spec parts and reduces downstream corrective costs.

Enhanced Process Control and Capability Analysis

CMM data enables statistical process control, helping teams tune tools, fixtures, and machining strategies.

Support for Complex Geometries and Tight Tolerances

CMMs handle multi-feature, multi-datum parts that are impractical to gauge with manual tools.

Improved Compliance and Traceability

Comprehensive reports and calibration records support regulatory and customer audit requirements.

Fast Product Development and Time to Market

Rapid prototyping validation shortens design iterations and accelerates production readiness.

Cost Efficiency Through Scalable Inspection Solutions

Automated CMM routines scale inspection cost-effectively across small to medium production runs.

Strengthened Customer Confidence and Brand Reputation

Demonstrable measurement rigor earns trust from OEMs and downstream suppliers.

Advanced CMM Capabilities

Modern CMMs integrate optical and laser scanners, multi-sensor heads, and automated part loading to expand throughput and capture freeform surfaces. Software-driven alignment to CAD and real-time analytics make CMMs central to Digital Twin and Industry 4.0 strategies.

When Is CMM the Right Tool?

Choose CMM inspection when parts require tight tolerances, when GD&T compliance is mandatory, or when complex geometry demands traceable, 3D verification. For ultra-high-volume simple features, dedicated gauges may be more economical — but CMMs shine in flexibility and data richness.

Conclusion

CMM inspection is a cornerstone capability for any quality-driven manufacturer or supplier. At Toolingsun, our one-stop service integrates design feedback, prototyping, and full CMM inspection to ensure parts meet spec the first time.

Have a part that needs precision verification or run-to-run quality control? Contact Toolingsun today to discuss inspection plans, request sample reports, or arrange a measurement review. We’re ready to partner with you to turn measurement data into better manufacturing outcomes.