When it comes to manufacturing intricate plastic parts with high precision, injection molding stands as the go-to process for countless industries. However, many manufacturers are taken aback by the price tag that comes with custom injection molds. So, what makes these molds so expensive? And is there a more affordable alternative for companies seeking cost-effective solutions? In this post, we will dive into the complexities of injection mold pricing, explore the reasons behind the high costs, and look at some alternative manufacturing methods that might suit your needs better.

At Toolingsun, we understand that the cost of custom molds can be a critical factor for many businesses. As a high-quality manufacturer with extensive experience in providing custom services for plastic injection molding, we aim to help our clients navigate the complexities of mold manufacturing while offering cost-effective alternatives. Read on to understand why these molds can be costly and what options you can explore for your manufacturing needs.

What Are Injection Molds and Why Are They Expensive?

Injection molds are custom-designed tools that play a pivotal role in the mass production of plastic products. These molds are used in the injection molding process, where molten plastic is injected into the mold cavity to form a solid part. The process is renowned for its precision and ability to create complex geometries in high volumes.

However, producing these molds involves numerous challenges and costs that contribute to their expensive nature. Below are the key factors that drive up the cost of custom injection molds:

1. Precision Engineering and Design Expertise

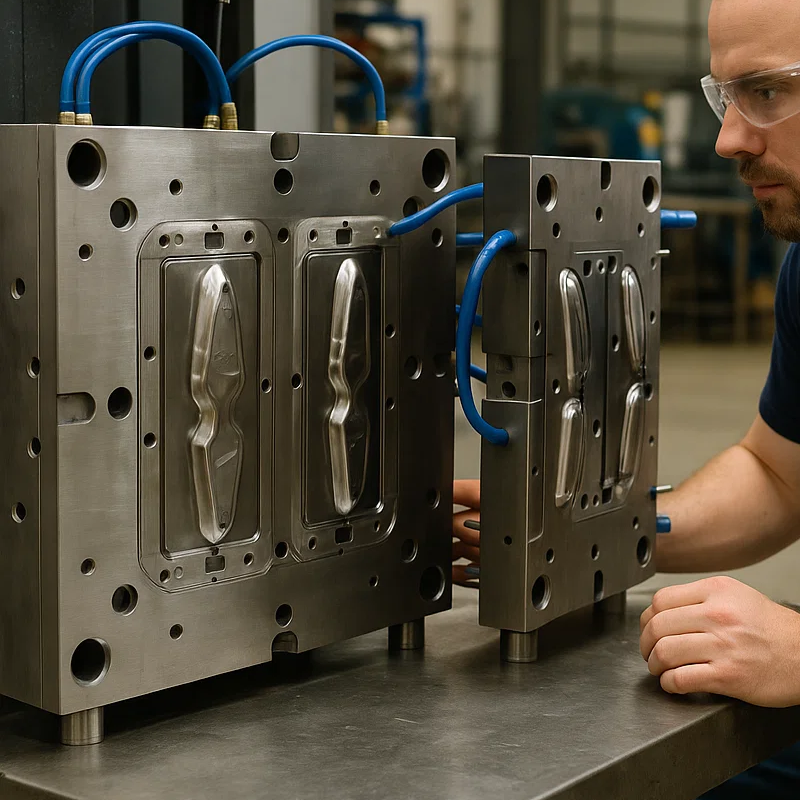

Custom injection molds require precision engineering to meet tight tolerances and intricate designs. Engineers and designers must use sophisticated software and technology to ensure that the mold will produce high-quality parts repeatedly. This level of precision requires not only expert skills but also time-consuming work, both of which contribute to higher costs. At Toolingsun, our in-house team of experienced engineers ensures that every custom mold is designed to meet your exact specifications, minimizing the risk of defects or errors during production.

2. Advanced Machining Techniques

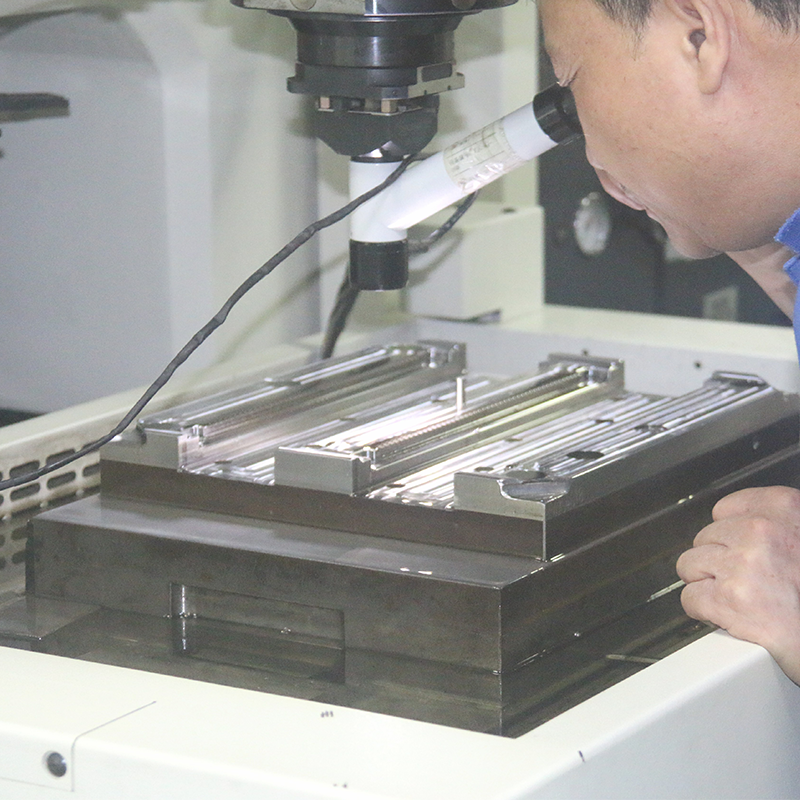

The process of creating injection molds involves high-end machinery like CNC machining and Electrical Discharge Machining (EDM). These techniques are used to carve and shape the mold from solid blocks of metal, such as hardened steel or aluminum, which are known for their durability and ability to withstand high pressures and temperatures. The use of such advanced technologies adds to the overall manufacturing cost.

Moreover, molds often need to be tested and refined throughout the production process, which adds additional time and costs. Our factory, Toolingsun, employs state-of-the-art machinery and cutting-edge technology to ensure every mold we produce meets the highest standards of quality and precision.

3. Material Selection

The materials used to make injection molds play a significant role in the cost. Molds made from high-quality steel or other durable metals are essential to withstand the extreme conditions of the injection molding process, which includes high pressure, temperature fluctuations, and constant wear and tear. These materials are expensive and thus directly impact the cost of the mold. As a supplier committed to providing cost-effective solutions, we at Toolingsun carefully select materials that balance durability and cost efficiency for every project, ensuring long-term value for our clients.

4. Prototyping and Testing

Before the mold is ready for production, prototyping and testing are essential steps to ensure that the mold design functions properly. During this phase, prototypes are created and tested for issues like fit, finish, and overall functionality. If any flaws are found, the mold must be adjusted, and another round of prototyping and testing takes place. This iterative process of refinement is crucial to ensure the mold meets all requirements, but it also increases the overall cost.

Alternative Options for Injection Molds

While custom injection molds are indispensable for large-scale production, the high upfront costs may not always be feasible for all companies, especially those requiring low-volume production or prototyping. Fortunately, there are several alternative manufacturing methods that can offer more affordable solutions for your needs.

1. 3D Printing

3D printing has emerged as an alternative for low-volume production and rapid prototyping. It allows designers to create prototypes quickly, test designs, and iterate without the hefty investment required for traditional mold production. While 3D printing is a more affordable option in terms of upfront costs, it comes with limitations such as slower production speeds and material constraints. Additionally, the surface finish of 3D-printed parts may not match the smoothness and precision of injection-molded parts.

At Toolingsun, we provide comprehensive custom services that include both traditional molding and 3D printing for prototyping, allowing you to evaluate design options without the full cost commitment.

2. Soft Tooling (Urethane Molding)

Soft tooling, also known as urethane molding or silicone molding, is a more affordable solution for short production runs or prototypes. It involves creating molds from soft materials such as silicone or urethane rubber, which can be used to produce a limited number of parts without the high initial costs associated with hard tooling. While this method works for low-volume runs, the molds wear out faster and may not provide the same level of precision or durability as traditional injection molds.

Soft tooling can be a good fit for businesses looking to produce a limited number of parts or conduct testing before committing to a full-scale production run. Toolingsun offers soft tooling services that provide flexibility and affordability without compromising quality.

3. Metal Stamping

For projects involving high-volume production of metal parts, metal stamping can be a cost-effective alternative to injection molding. This method involves using a die to shape and cut metal sheets into the desired form. It is suitable for producing parts with simpler geometries and is known for its high production speed and efficiency.

However, metal stamping may not be ideal for more complex designs, as it is better suited for parts with simpler shapes. If you’re considering metal components for your product, Toolingsun can help assess whether metal stamping is the right option for you.

4. Die Casting

Die casting is another alternative to injection molding, particularly for high-volume production of metal parts. It involves injecting molten metal into a mold to create the final part. Die casting offers fast production speeds and is suitable for parts with intricate designs, but it may not offer the same precision as injection molding.

Similar to metal stamping, die casting works best for parts with relatively simple geometries, and it requires significant upfront tooling costs. If you need a balance between cost and precision for your metal parts, die casting may be worth considering. Toolingsun can offer guidance on choosing the best process based on your project’s requirements.

Choosing the Right Manufacturing Partner

When selecting a manufacturer for your custom molds, it’s essential to partner with a company that understands both your technical needs and budget constraints. At Toolingsun, we offer a one-stop service that integrates design, prototyping, and manufacturing, ensuring the entire production process is streamlined and cost-effective.

Our factory is equipped with the latest technology and staffed by skilled professionals who specialize in high-quality custom injection molds. Whether you’re looking for large-scale production or low-volume prototyping, we provide affordable, high-quality solutions tailored to your needs.

Conclusion

While custom injection molds are a critical component of modern manufacturing, their cost can be prohibitive for some businesses. Understanding the reasons behind the high costs can help you make more informed decisions about your manufacturing strategy. At Toolingsun, we offer custom services and provide expert guidance on choosing the right manufacturing process for your needs. If you’re looking for a reliable manufacturer that can deliver top-quality results without breaking the bank, contact us today to discuss how we can assist with your next project. Let’s explore the best options together!