In the world of injection molding, ensuring that the final part meets precise design specifications is crucial. However, many injection molders face a challenge when it comes to mold adjustment: molds rarely arrive with perfect dimensions, and significant modifications are often required after the initial mold sampling. Traditionally, molders rely on outside toolmakers to make these adjustments, which can lead to delays, added costs, and extended project timelines. At Toolingsun, we address these challenges by offering in-house mold contouring, a process that significantly reduces project timelines, increases efficiency, and lowers costs for our clients.

In this blog, we’ll explore the benefits of in-house mold contouring, why it’s essential for faster project execution, and how Toolingsun’s expertise in mold-making allows us to provide faster, more precise, and cost-effective solutions for our clients.

The Problem with Outsourcing Mold Adjustments

Injection molders typically rely on external mold builders to custom-create molds based on client specifications. However, these molds are rarely perfect when they arrive. After receiving the mold, most companies must conduct testing and inspections, often finding that the mold doesn’t meet the required specifications. At this point, adjustments are necessary to fine-tune the mold and bring it into compliance with the design. Unfortunately, this process usually involves sending the mold out to external toolmakers for modifications, resulting in delays and additional costs.

These mold adjustments can take anywhere from three to five weeks per iteration, with costs ranging from $1,000 to $10,000 per round of adjustments, depending on the complexity of the part. Beyond the costs of the adjustments themselves, additional expenses such as mold transportation, toolmaker fees, inspection costs, and sampling fees can add up quickly, further extending the timeline.

The Benefits of In-House Mold Contouring at Toolingsun

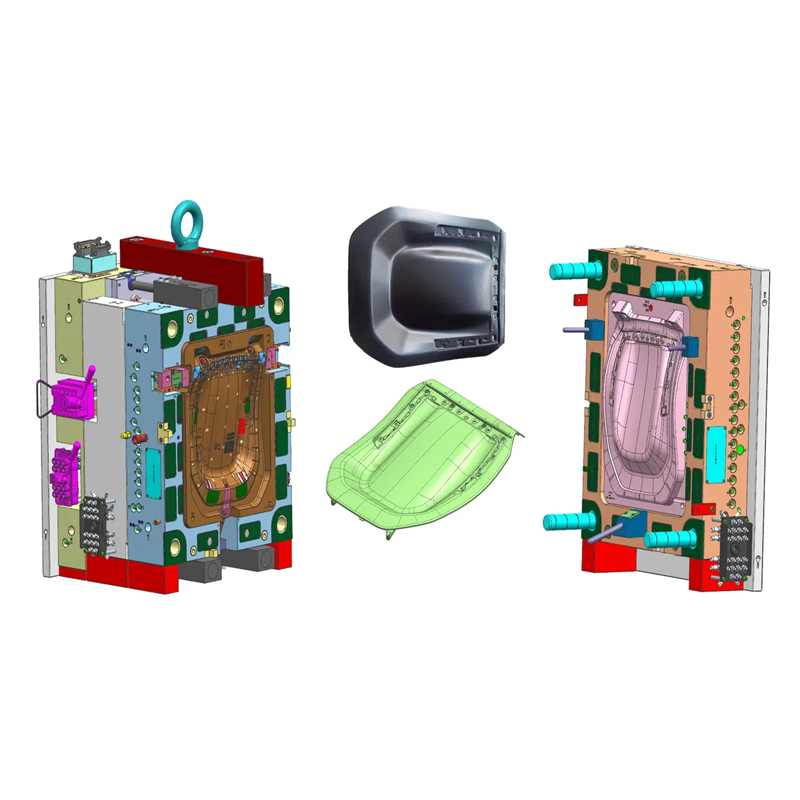

At Toolingsun, we’ve taken a different approach by providing in-house mold contouring capabilities. This allows us to adjust molds after initial sampling, making changes to the core and cavity geometry to meet the precise specifications required. Our experienced team of toolmakers uses advanced technologies, such as Electrical Discharge Machining (EDM) and Computer Numerical Control (CNC), to make these modifications in-house, drastically reducing the time and costs typically associated with outsourcing these processes.

Key Advantages of In-House Mold Contouring

- Faster and More Accurate Communication and Decision-Making

By performing mold adjustments in-house, Toolingsun eliminates the need for external communication, streamlining the decision-making process. Our engineers and toolmakers work together directly, ensuring faster responses and a more coordinated workflow. This reduces delays and ensures that the adjustments are made to the exact specifications required without the back-and-forth communication often involved in outsourcing. - Fewer Adjustment Iterations

When mold adjustments are outsourced, the process often involves multiple iterations to achieve the desired result. With in-house capabilities, we can make adjustments more efficiently and accurately, reducing the number of iterations needed. This leads to quicker turnaround times and helps prevent costly delays. - More Control Over the Mold Shop Schedule

In-house mold contouring gives us greater control over the mold shop’s schedule. We’re not dependent on external suppliers, which means we can schedule adjustments as needed and prioritize projects without waiting for third-party toolmakers to become available. This flexibility helps us deliver molds more quickly, ensuring faster project execution. - Fewer Mistakes and Higher Precision

With the entire process managed internally, we reduce the risk of errors that can occur when multiple parties are involved. Our in-house team is highly skilled and experienced, which means fewer mistakes during mold adjustments. The result is a more precise mold, and in turn, a higher-quality final product. - Lower Overall Costs

While there are some upfront costs associated with maintaining in-house mold contouring capabilities, the long-term savings are significant. By eliminating external toolmaker fees, mold transportation costs, and additional sampling expenses, Toolingsun can offer a more cost-effective solution. The reduced timeline also allows for faster time-to-market, which can be crucial for businesses looking to meet tight deadlines or stay ahead of the competition.

Toolingsun’s In-House Mold Contouring Process

At Toolingsun, we’ve developed a streamlined process for in-house mold contouring that ensures accuracy, efficiency, and cost savings for our clients. Here’s a closer look at the steps involved in our process:

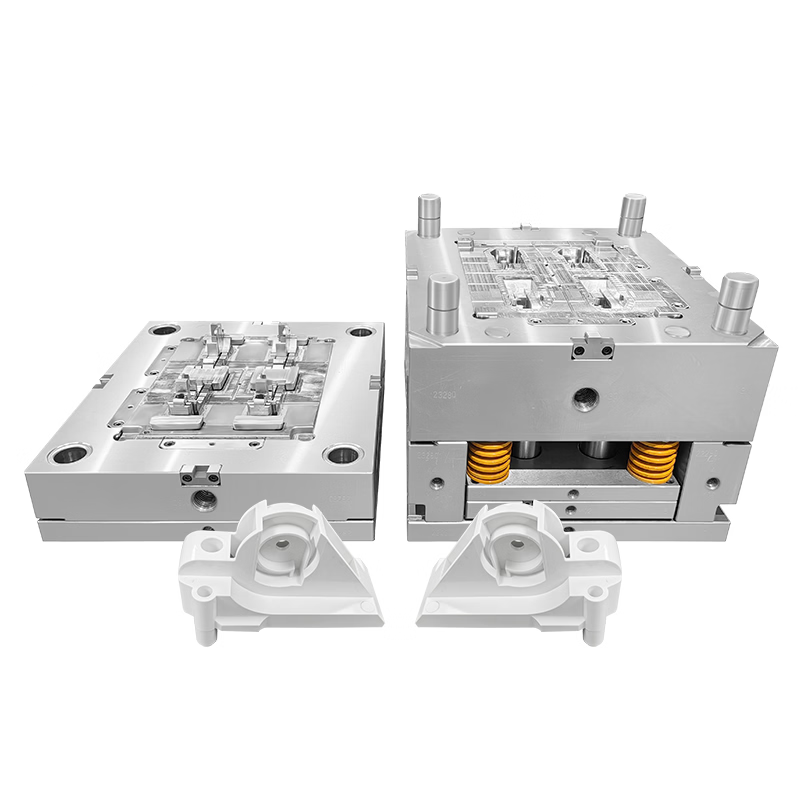

- Receiving the Mold in Steel-Safe Condition

We begin by receiving molds from external sources (domestic or international) in a steel-safe condition. This means that the molds are slightly larger than the required specifications, allowing us to make adjustments as needed. - Setting Up the Injection Process Using Scientific Molding

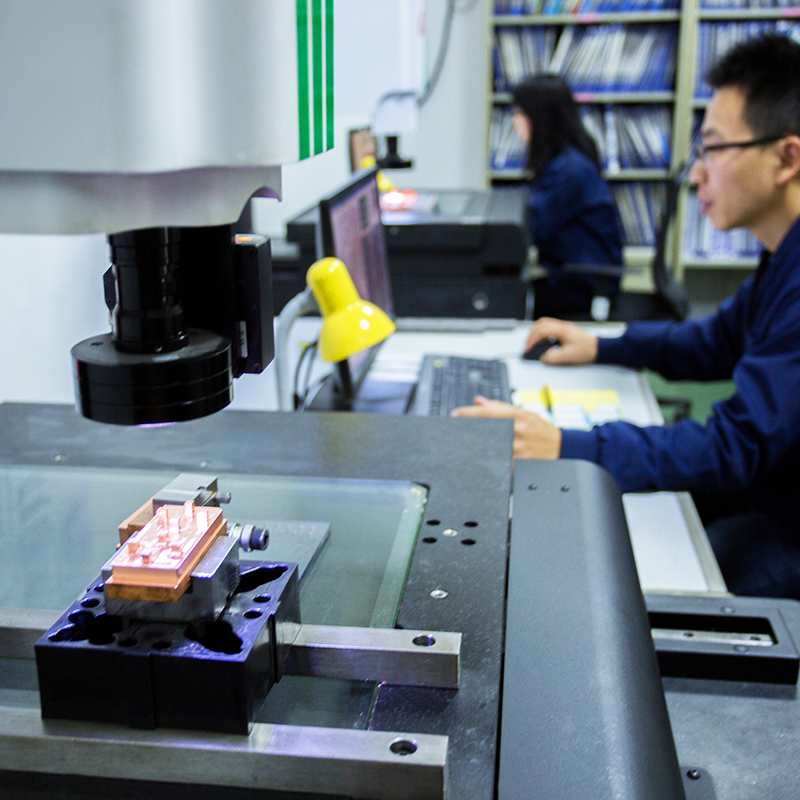

Our team sets up the injection process, utilizing scientific molding methodology to ensure precision and consistency during mold testing. - Measuring Parts and Conducting Capability Studies

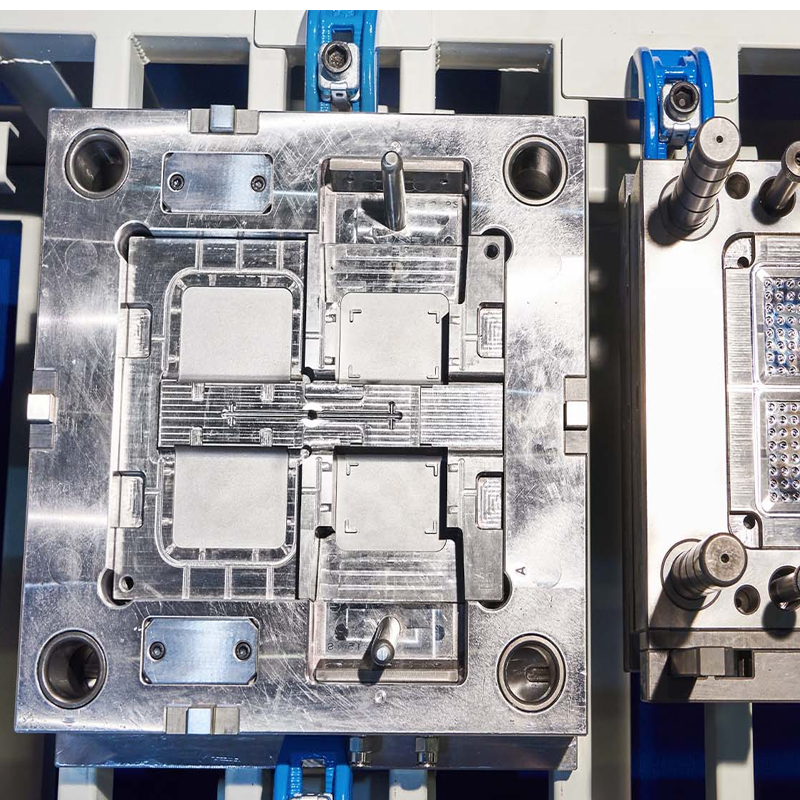

After the initial sampling, we measure the parts and conduct capability studies (if needed) to identify any discrepancies and determine where adjustments are necessary. - Modifying the CAD Model

If required, our engineers and toolmakers modify the part and/or mold CAD model. Using the 3D mold design data, we can make accurate adjustments to the mold without delays. - Fine-Tuning the Mold with EDM and CNC Machines

We use advanced technologies such as EDM and CNC machining to make fine adjustments to the mold. These techniques allow for highly precise modifications to the mold’s core and cavity geometry. - Final Sampling, Inspection, and Submission

Once the adjustments are made, we perform final sampling and inspections to ensure that the mold meets all specifications. After the mold passes inspection, it’s ready for mass production.

Why Choose Toolingsun for In-House Mold Contouring?

At Toolingsun, we pride ourselves on our ability to provide end-to-end solutions for mold-making and injection molding. By handling mold contouring in-house, we offer several advantages that save our clients valuable time and money. Here are a few reasons why businesses choose Toolingsun for their injection mold-making needs:

- Expertise in Mold-Making: Our in-house team consists of experienced toolmakers who are proficient in using the latest equipment to ensure the highest quality molds.

- Faster Time-to-Market: In-house mold contouring helps reduce the overall project timeline, enabling our clients to get their products to market faster.

- Cost Savings: By eliminating the need for third-party toolmakers, we reduce costs associated with mold transportation, toolmaker fees, and additional sampling.

- Superior Quality Control: Our in-house process ensures precise adjustments, minimizing errors and delivering high-quality molds that meet the exact specifications required.

Conclusion: The Value of In-House Mold Contouring at Toolingsun

In-house mold contouring is a critical capability that can save time, reduce costs, and improve the overall quality of injection molded parts. By offering this service, Toolingsun ensures that our clients experience faster project execution, fewer mistakes, and more accurate final products. Our expertise in mold-making and our advanced equipment, including EDM and CNC machining, allow us to fine-tune molds efficiently, ensuring they meet the precise specifications required for mass production.

If you’re looking for a mold-making partner who can streamline your project timeline and reduce costs, contact Toolingsun today. Let us help you take your products from design to production with precision, speed, and cost-effectiveness.